Polypropylene composite used for injection moulding splicing floor and preparation method thereof

A technology of injection molding and compounding, which is applied in the direction of building structure, building, floor, etc., to achieve the effects of good resilience, stable color and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

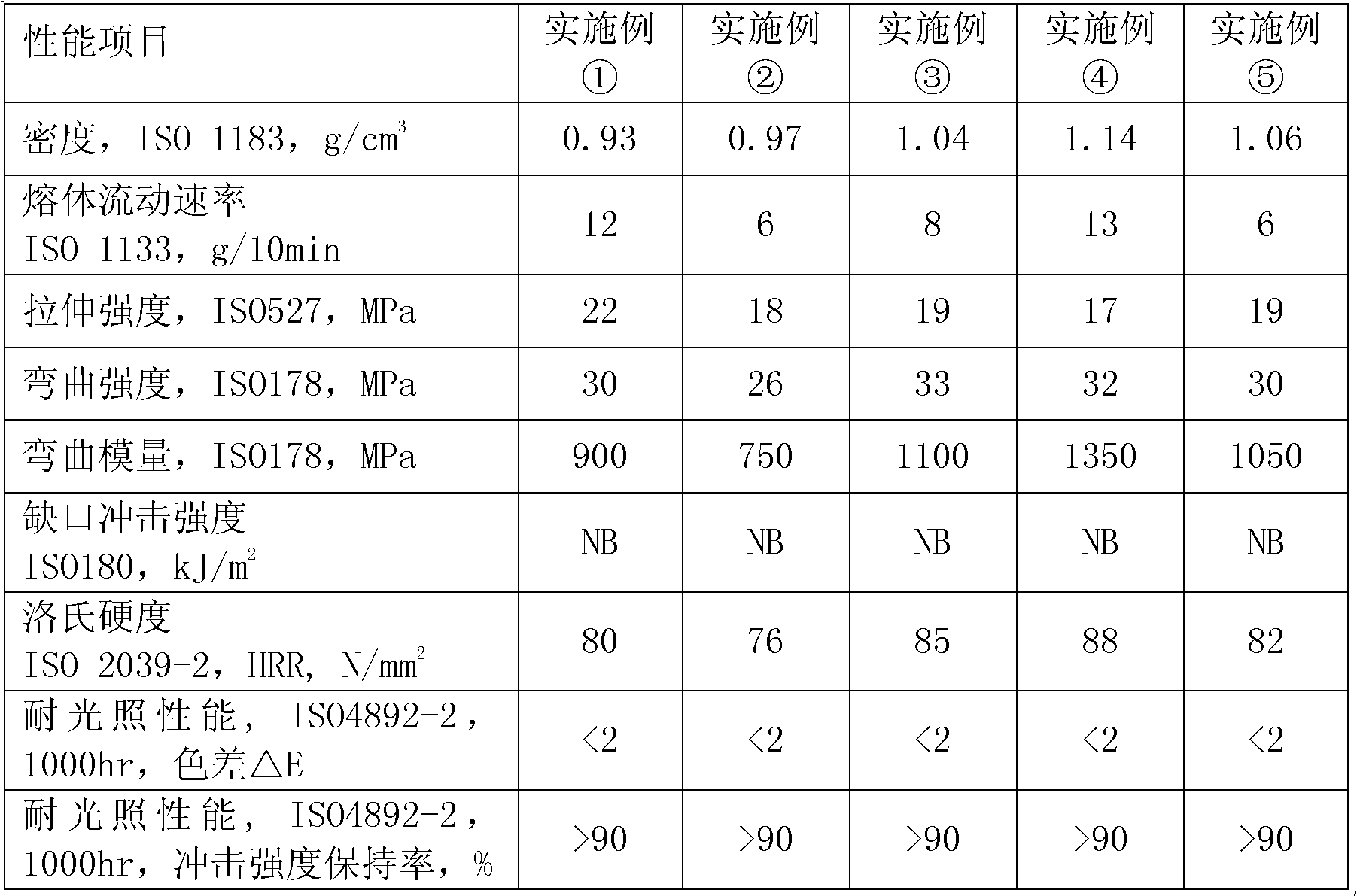

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment, the present invention will be further described.

[0025] Prepare polypropylene composites respectively according to the formula described in Table 1, wherein: the PP resin used is AZ564 of Singapore TPC, and its MFR is 24g / 10min (the test condition of MFR is: 230 ℃, 2.16Kg); the SEBS used is Kraton The white oil used is 100# refined white oil; the average particle size of talcum powder used is 1250 mesh, and the average particle size of calcined kaolin is 800 mesh; the weather-resistant toner used is inorganic (such as titanium dioxide, carbon black, ultramarine, Iron oxide red) and organics (such as phthalocyanine blue, phthalocyanine green, permanent red, permanent yellow); other additives used include light stabilizers UV-531 and UV-2908, antioxidant 1010 And 168, processing aid erucamide.

[0026] Wherein the preparation steps are:

[0027] ①Put the toughening agent and part of the copolymerized polypropylene into the high mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com