Rotating disc type aircraft engine

An aero-engine, turntable-type technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as waste, insufficient utilization of fuel combustion energy, and large impact force of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

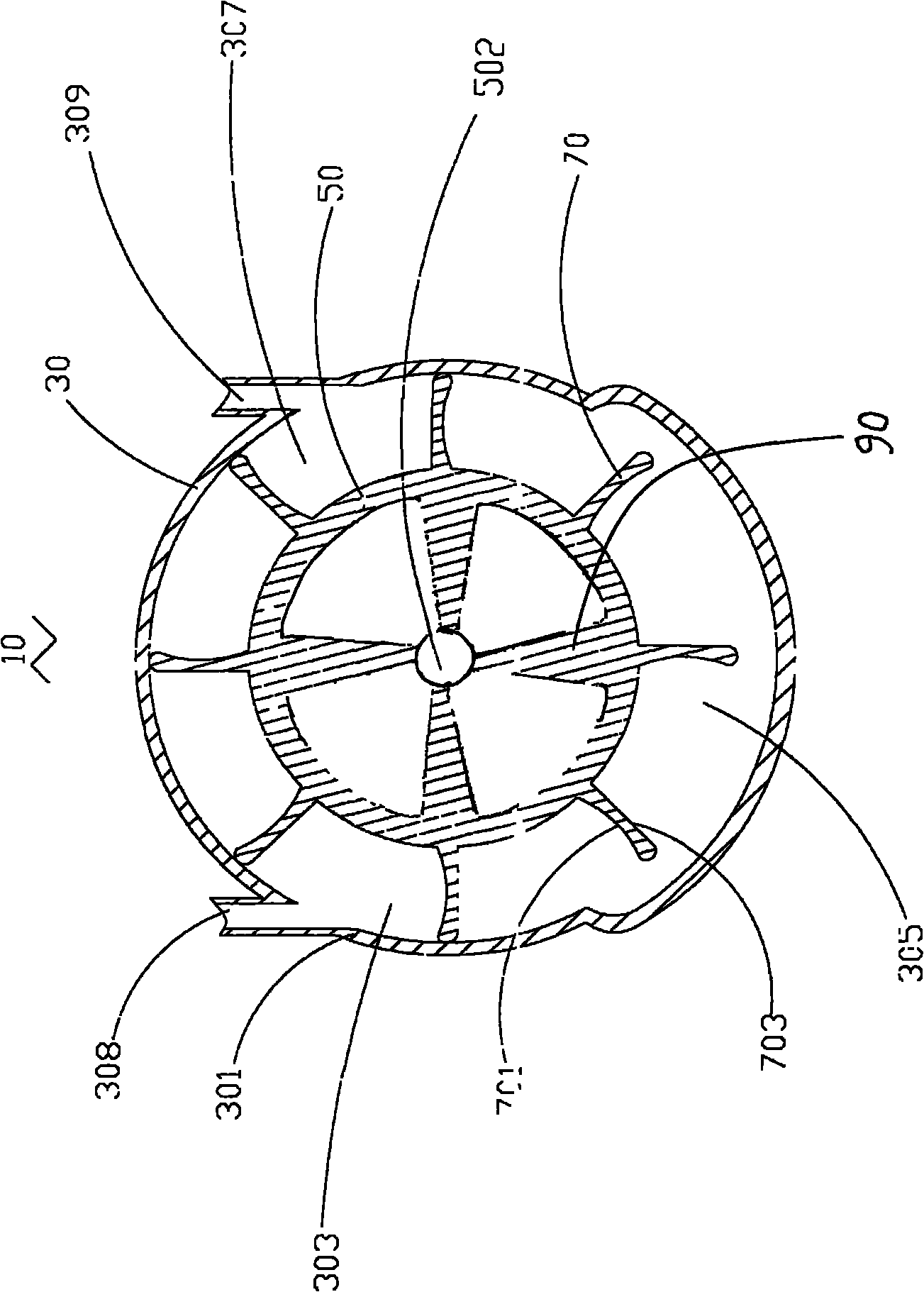

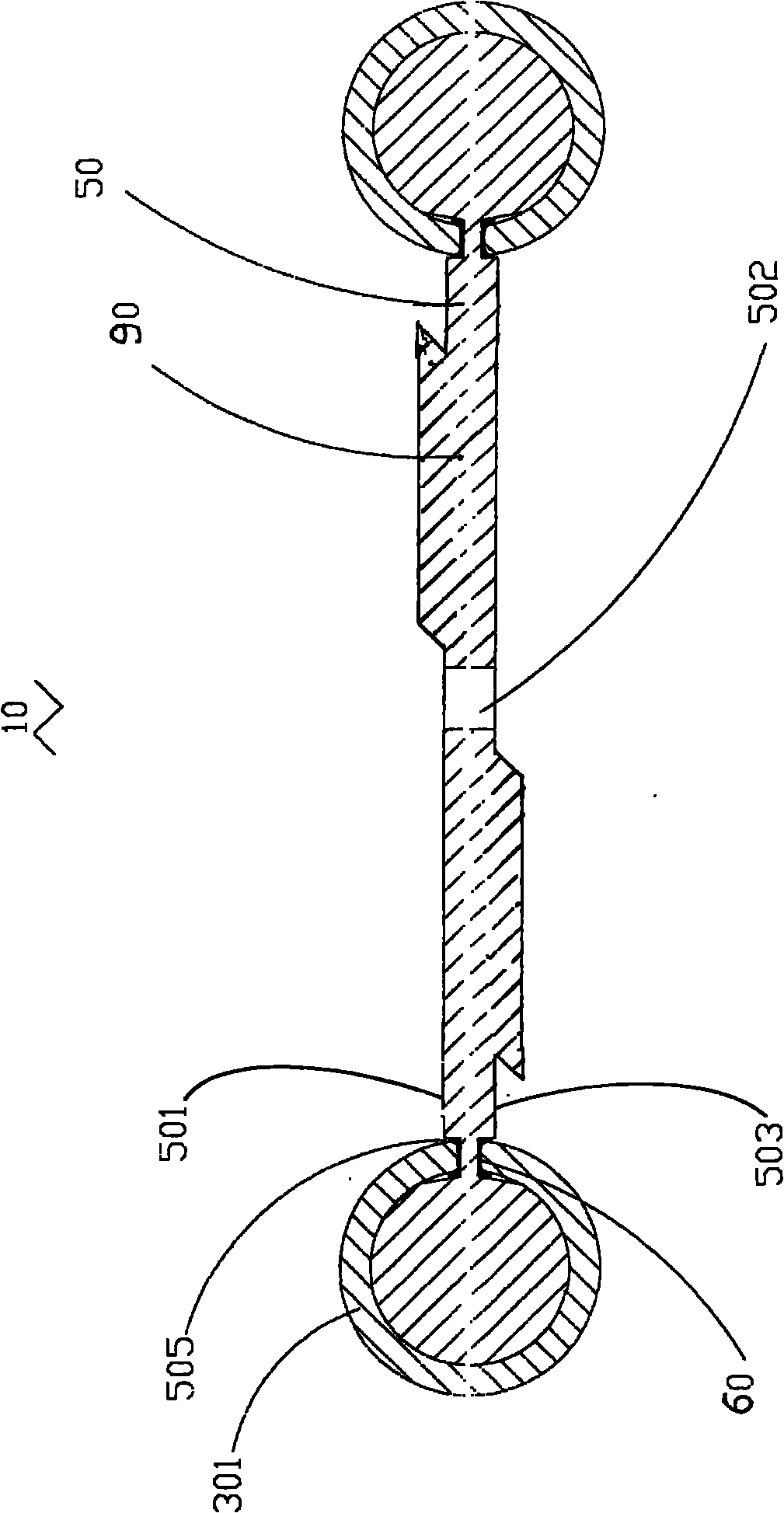

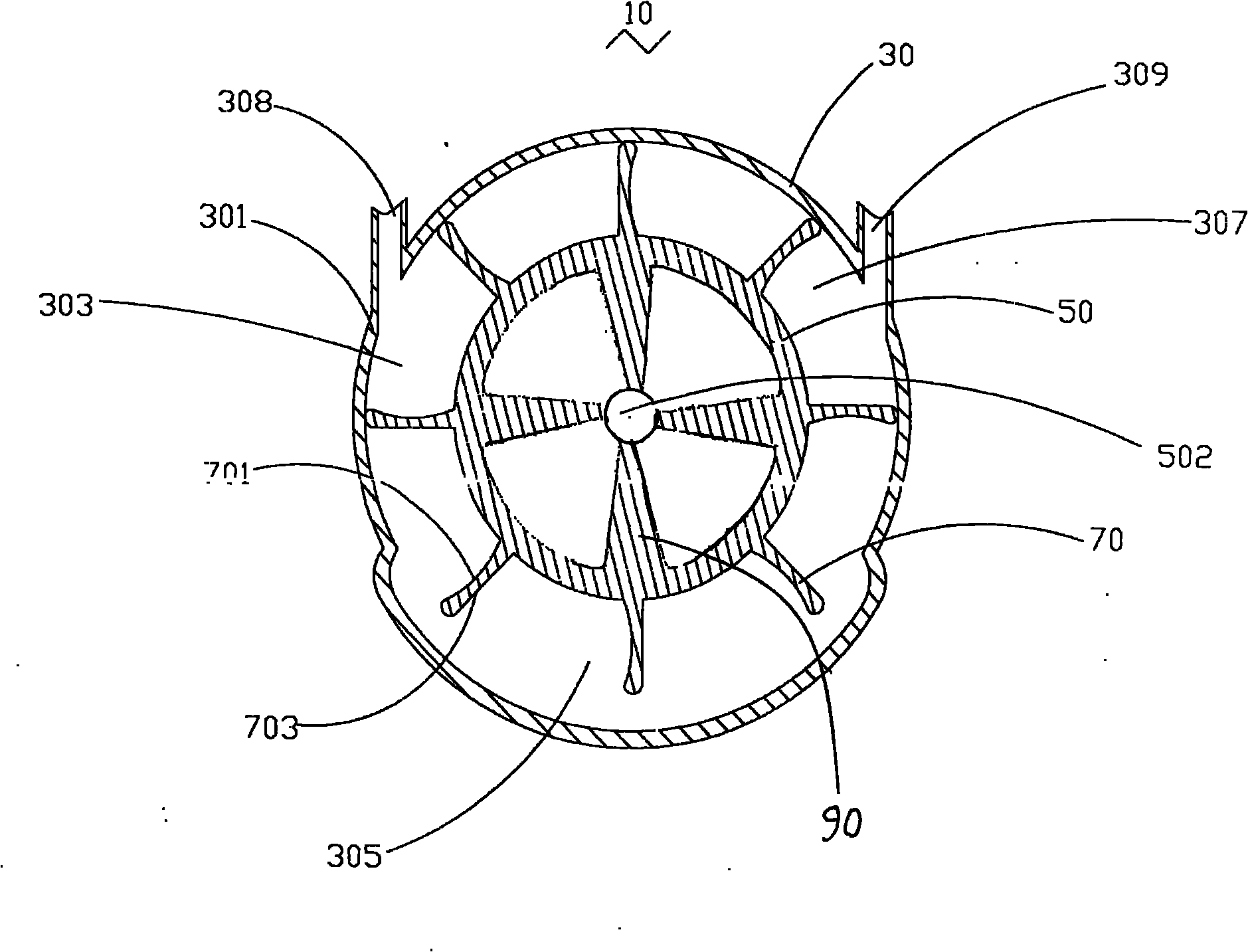

[0007] see figure 1 , the present invention provides a rotary disc aero-engine 10 , which includes a cylinder 30 , a rotary disc 50 , a piston 70 connected to the rotary disc 50 and blades 90 . The engine 10 is also provided with a combustion chamber (not shown in the figure), and the combustion chamber is connected to the cylinder block 30 .

[0008] Please also refer to figure 2 , the cylinder body 30 is generally hollow and annular. In this embodiment, the cylinder body 30 is provided with a cylinder wall 301, and the inner circumference of the cylinder wall 301 of the cylinder body 30 is provided with a gap from the horizontal direction, so that the cross-sectional shape of the cylinder body 30 is C-shaped. The cylinder wall 301 encloses a cavity. The cavity 302 of the cylinder body 30 includes an intake cavity 303 , a pressure release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com