Integration online detection system for full-automatic wheel dynamic balance and hop

A detection system and jump detection technology, applied in the static/dynamic balance test, measuring device, machine/structural component test, etc., can solve the problems of unable to realize mixed line detection, unable to meet the needs of online detection, etc., to achieve balance speed High, guaranteed consistency, high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

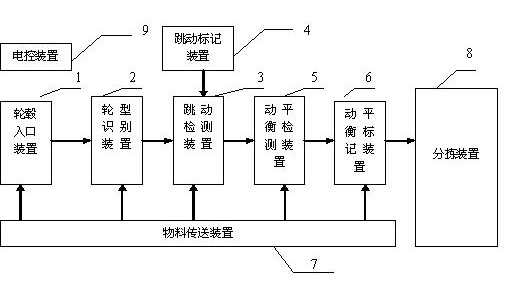

[0019] like figure 1 As shown, the fully automatic wheel dynamic balance and runout integrated online detection system includes: wheel hub inlet device, wheel type identification device, runout detection device, runout marking device, dynamic balance detection device, dynamic balance identification device, sorting device, material transfer device, electronic control device. Hub inlet device 1, wheel type identification device 2, runout detection device 3, runout marking device 4, dynamic balance detection device 5, dynamic balance marking device 6, and sorting device 8 are connected into an organic whole through material conveying device 7.

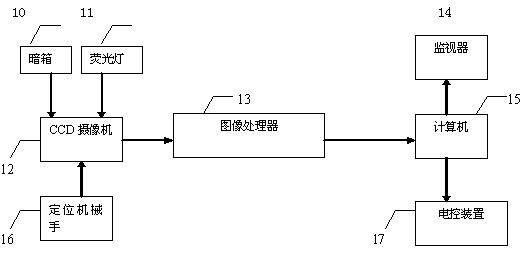

[0020] like figure 2 As shown, the wheel type recognition device 2 is composed of a dark box 10, a fluorescent lamp 11, a CCD camera 12, an image processor 13, a monitor 14, a computer 15, a positioning manipulator 16, and an electric control device 17. The CCD camera 12 is installed on the top of the dark box 10 On the bracket, a fluo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap