Manufacturing execution system (MES) for manufacturing process of printed circuit board (PCB)

A technology of process equipment and alarm system, applied in the field of MES system, can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

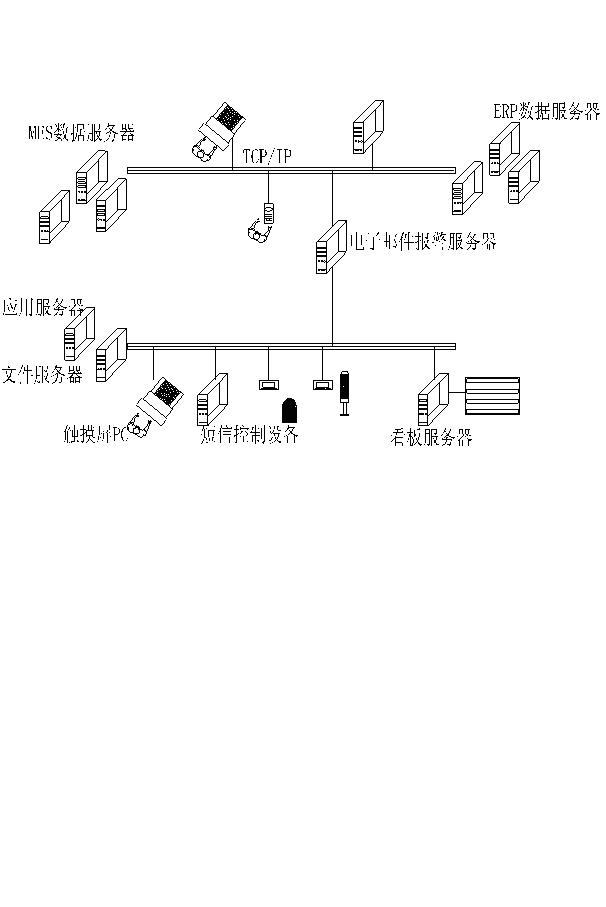

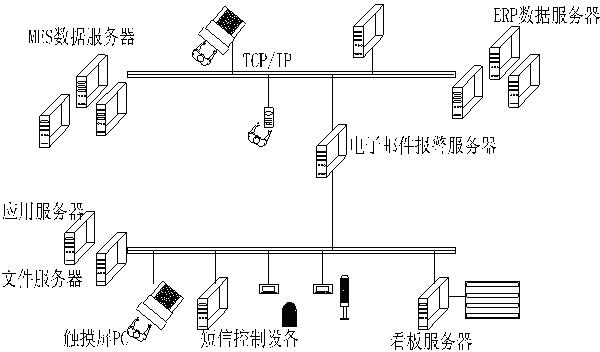

[0018] The invention provides an MES system related to the PCB manufacturing process. The MES system is positioned as an execution layer between the planning layer and the field automation system, and is mainly responsible for workshop production management and scheduling execution.

[0019] An MES system related to the PCB manufacturing process of the present invention is carried out in sequence according to the following three stages: the first stage, the second stage and the third stage connected with the upper ERP system.

[0020] Specifically, the first stage further includes the following steps: transfer the data from the ERP engineering system to the engineering parameters of each process equipment, monitor each production machine equipment in real time, display the downtime on the on-site LED electronic kanban, and analyze the relationship between each production machine equipment and The utilization rate of each process equipment provides an integrated analysis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com