Light emitting diode array structure and manufacturing method thereof

A technology of light-emitting diodes and array structures, which is applied to electrical components, electrical solid-state devices, circuits, etc., and can solve problems such as difficult processes and damage to electrical connection structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

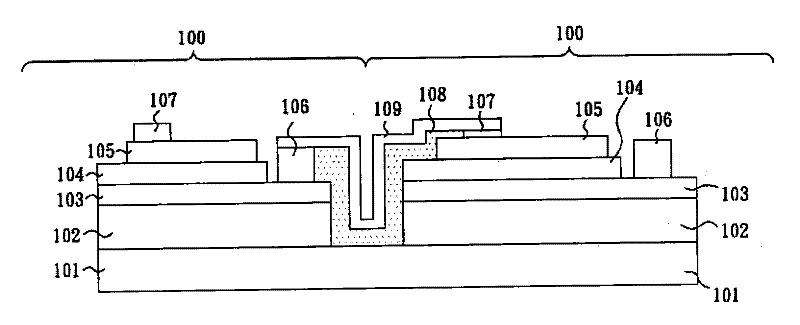

[0032] The invention discloses a light emitting diode array structure and a manufacturing method thereof. In order to make the description of the present invention more detailed and complete, please refer to the following description and cooperate with Figures 2A to 4 's icon.

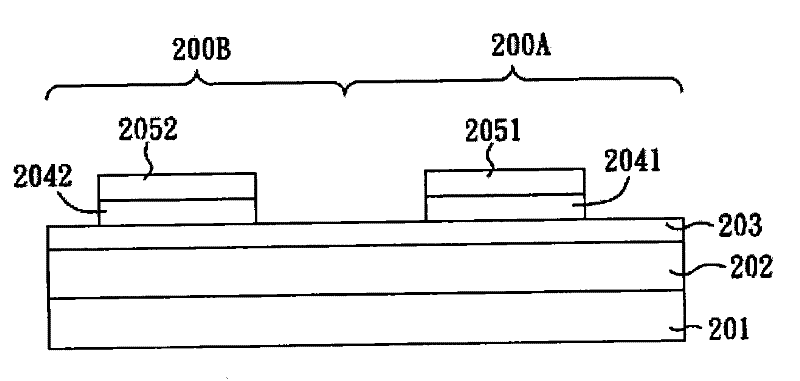

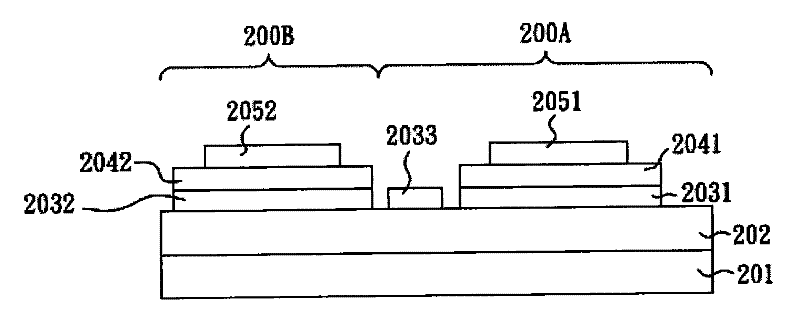

[0033] Figures 2A to 2K It is a schematic structural diagram of the manufacturing process according to the first embodiment of the present invention. like Figure 2A As shown, it includes a temporary substrate 201, a plurality of first light-emitting stacks 200A and a plurality of second light-emitting stacks 200B, wherein the plurality of first light-emitting stacks 200A and the plurality of second light-emitting stacks 200B are sequentially formed in the temporary on the substrate 201 . The first light emitting stack 200A includes an n-type semiconductor layer 203 formed on the temporary substrate 201, a first active layer 2041 formed on the n-type semiconductor layer 203, and a first p-type se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com