Chemical metallurgical connecting method for heat pipe and radiating fins

A heat-dissipating fin and chemical metallurgy technology, applied in the field of heat-dissipating devices, can solve the problems of reduced production efficiency, easy change of fin position, insignificant reduction of thermal resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

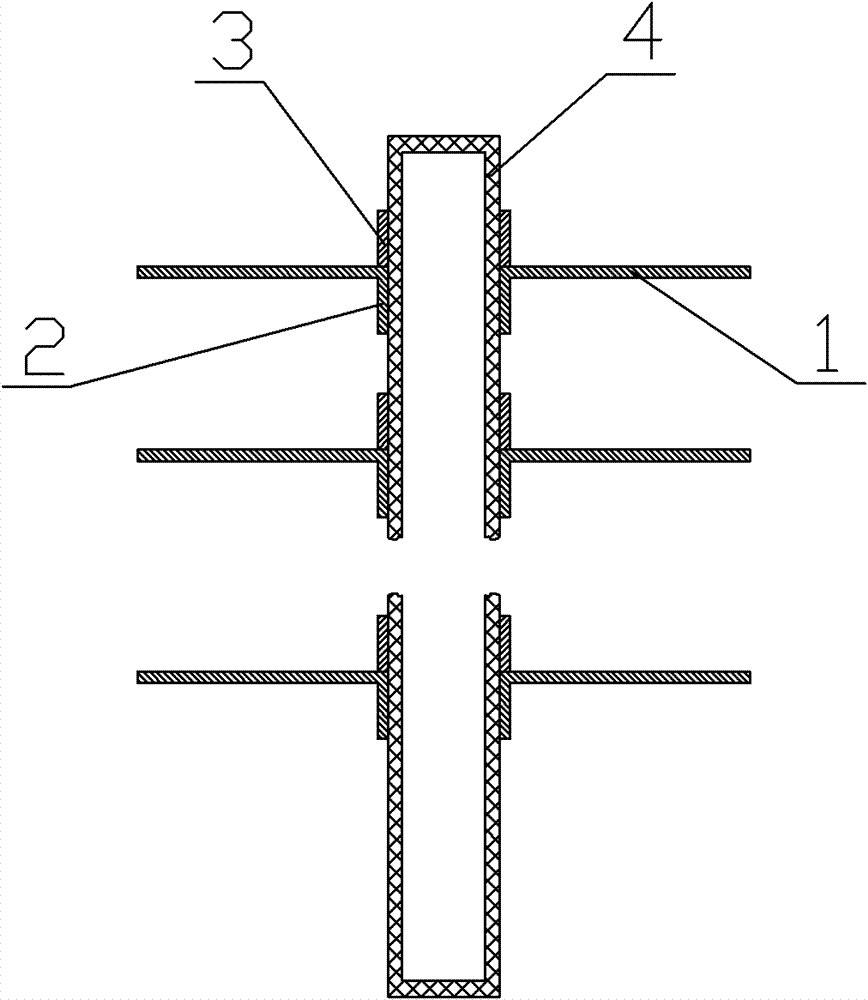

[0017] Such as figure 1 As shown, the cooling fin 1 with flange 2 is interspersed on the heat pipe 4, the outer diameter of the heat pipe 4 is 10.000mm, the tolerance is +0.000mm~+0.050mm, the inner diameter of the flange 2 is 10.000mm, the tolerance is + 0.100mm~+0.500mm, the outer diameter is 10.600mm, the height is 2.000mm, the thickness of the cooling fin 1 is 0.300mm; the tin ring 3 is inserted along the heat pipe on the side facing away from the flange 2, and the tin ring 3 is connected with the heat dissipation The fins 1 are in contact, so that a plurality of cooling fins 1 and tin rings 3 are socketed on the heat pipe repeatedly. The inner diameter of the tin ring 3 is 10.200mm, the outer diameter is 11.000mm, and the height is 4.000mm; then Place the socket piece in the heat treatment furnace along the downward direction of the flange 2, heat the tin ring 3 to melt into tin liquid, and the tin liquid penetrates into the matching gap between the flange 2 and the heat ...

Embodiment 2

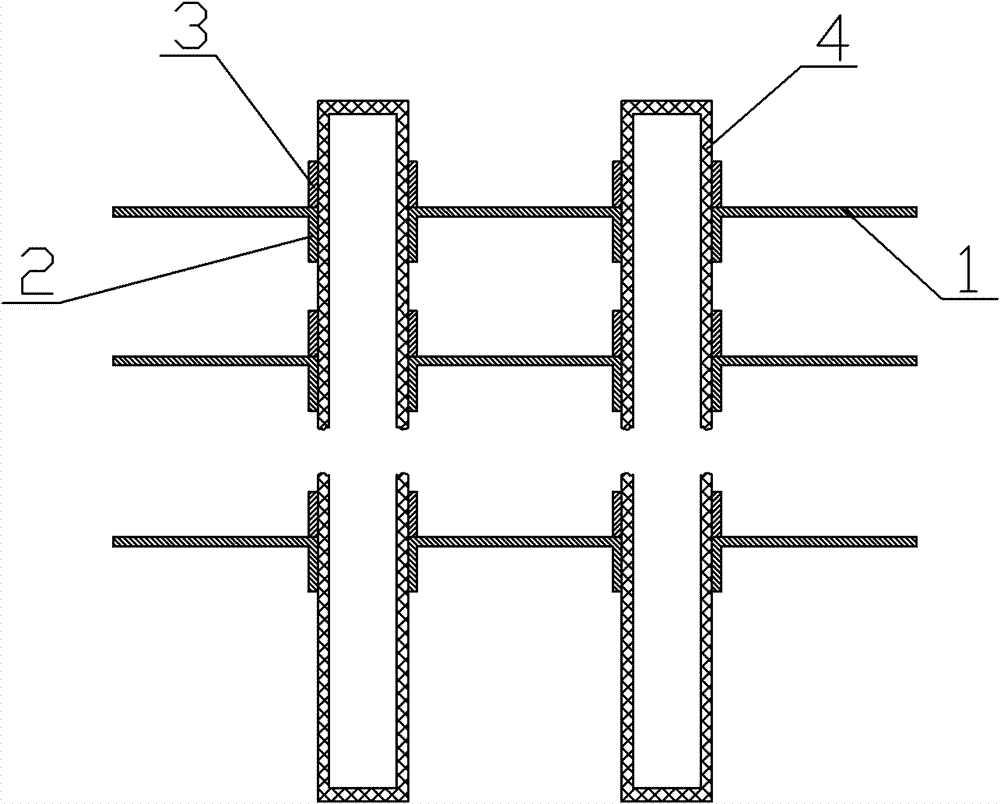

[0020] Such as figure 2 As shown, two heat pipes 4 are arranged in parallel, and the cooling fins 1 with flanging 2 are interspersed on the heat pipe 4. The outer diameter of the heat pipe 4 is 8.000mm, and the tolerance is +0.000mm~+0.050mm. is 8.000mm, the tolerance is +0.050mm~+0.200mm, the outer diameter is 8.600mm, the height is 2.000mm, and the thickness of the cooling fin 1 is 0.300mm; the tin ring 3 is inserted along the heat pipe on the side facing away from the flange 2, And the tin ring 3 is in contact with the heat dissipation fin 1, so that a plurality of heat dissipation fins 1 and the tin ring 3 are sleeved on the heat pipe repeatedly, and the inner diameter of the tin ring 3 is 8.100mm, and the outer diameter is 11.100mm , with a height of 3.000mm; then place the socket piece in a heat treatment furnace along the downward direction of the flange 2, heat the tin ring 3 to melt into tin liquid, and the tin liquid penetrates into the matching gap between the flan...

Embodiment 3

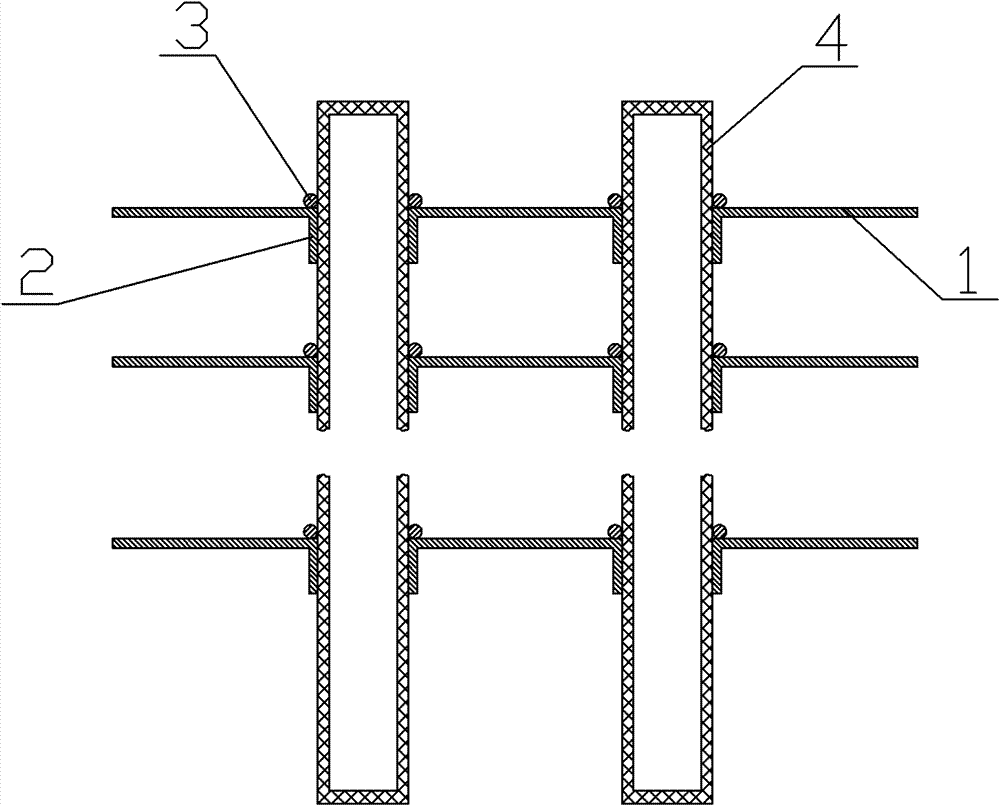

[0023] Such as image 3 As shown, two heat pipes 4 are arranged in parallel, and the cooling fins 1 with flanging 2 are interspersed on the heat pipes 4. 6.000mm, the tolerance is +0.050mm~+0.200mm, the outer diameter is 6.600mm, the height is 2.000mm, the thickness of cooling fin 1 is 0.300mm; And the tin ring 3 is in contact with the heat dissipation fin 1, so that a plurality of heat dissipation fins 1 and the tin ring 3 are sleeved on the heat pipe repeatedly, and the inner diameter of the tin ring 3 is 6.100mm, and the outer diameter is 13.200mm , with a height of 1.000mm; then place the socket piece in a heat treatment furnace along the downward direction of the flange 2, heat the tin ring 3 to melt into tin liquid, and the tin liquid penetrates into the matching gap between the flange 2 and the heat pipe 4 , to realize the chemical metallurgical connection between the heat pipe and the cooling fin; the width of the fitting gap is 2 μm to 25 μm; the distance between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com