Halogen-free flame-retardant resin composition and preparation method of prepreg and laminated plate

A technology of flame retardant resin and composition, applied in the fields of laminate, preparation of prepreg, and halogen-free flame retardant resin composition, to achieve the effect of reducing material cost, strong self-extinguishing property and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] a. Glue preparation:

[0055] At room temperature, add 50 parts of epoxy resin, 50 parts of cyclohexanone, 15 parts of toluene, and 20 parts of phosphazene flame retardant into the glue tank respectively, and after stirring for 0.5 hours at 20°C, add inorganic flame retardant two 25 parts of silicon oxide, 15 parts of 4,4-diaminodiphenylmethane, 1 part of accelerator 2-methylimidazole, stir for 1 hour, take a sample, and use a knife to test the molding time of the glue (160°C hot plate) for 200 seconds , the glue solution is prepared;

[0056] b. Glass cloth prepreg preparation:

[0057] The glass cloth is coated with halogen-free flame retardant resin glue through a vertical or horizontal gluing machine and pre-baked through the drying channel of the gluing machine. The 24m drying channel of the gluing machine is divided into 3 sections, each section is 8 m, and Determine the baking temperature range of the gluing machine drying tunnel and the speed and linear speed ...

Embodiment 2

[0061] a. Glue preparation:

[0062] At room temperature, add 50 parts of polyamine-imide resin, 40 parts of toluene, 25 parts of ethylene glycol dimethyl ether, and 10.5 parts of phosphazene flame retardant into the compounding tank respectively. After stirring at 50°C for 2 hours, add inorganic 10.5 parts of flame retardant aluminum hydroxide, 15 parts of bisphenol A epoxy resin as curing agent, 0.5 parts of boron trifluoride ethylamine as accelerator, stir for 1 hour, take samples, and test the molding time of the glue with the knife method (heated at 160 ℃ board) 600 seconds, the glue preparation is completed;

[0063] b. Glass cloth prepreg preparation:

[0064] (see Example 1 for the basic process, and see Table 1 below for specific process parameters);

[0065] c. Halogen-free flame-retardant glass cloth laminate pressing:

[0066] (See Example 1 for the basic process, and Table 2 for specific process parameters).

Embodiment 3

[0068] a. Glue preparation:

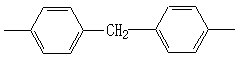

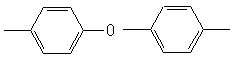

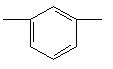

[0069] At room temperature, respectively add 70 parts of benzoxazine resin (structural formula 2 in the content of the invention), 20 parts of dimethylformamide, 35 parts of methyl ethyl ketone, and 3 parts of phosphazene flame retardant into the glue mixing tank, and stir at 60°C for 2 After 1 hour, add 20 parts of inorganic flame retardant magnesium hydroxide and 0.01 part of accelerator 2-phenylimidazole, stir for 1 hour, take samples, and use a knife to test the molding time of the glue (160°C hot plate) for 550 seconds. Prepared;

[0070] b. Glass cloth prepreg preparation:

[0071] (see Example 1 for the basic process, and see Table 1 below for specific process parameters);

[0072] c. Halogen-free flame-retardant glass cloth laminate pressing:

[0073] (See Example 1 for the basic process, and Table 2 for specific process parameters).

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com