A kind of halogen-free intumescent flame retardant containing ketone cyanuric acid structure and its synthesis method

A technology of intumescent flame retardant and cyanuric acid, which is applied in the fields of compounds, chemical instruments and methods, organic chemistry, etc. of Group 5/15 elements of the periodic table. The problems of complicated preparation steps of the burning agent, etc., can achieve the effect of high phosphorus and nitrogen content, reducing the loss of mechanical properties, and high flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 2.9727g triglycidyl isocyanurate in 30ml N,N-dimethylformamide into a 50ml three-neck flask, then dissolve 1.38g diethyl phosphite in 5ml N,N-dimethylformamide and add To the above-mentioned three-necked flask, under nitrogen protection, magnetic stirring and condensing and reflux, the temperature was raised to 150° C., and the reaction was carried out for 6 hours. Then concentrated by rotary evaporation and precipitated with dichloromethane to obtain the crude product TGIC-DEPP. The crude product was centrifuged and washed three times with dichloromethane, and finally the product TGIC-DEPP was obtained.

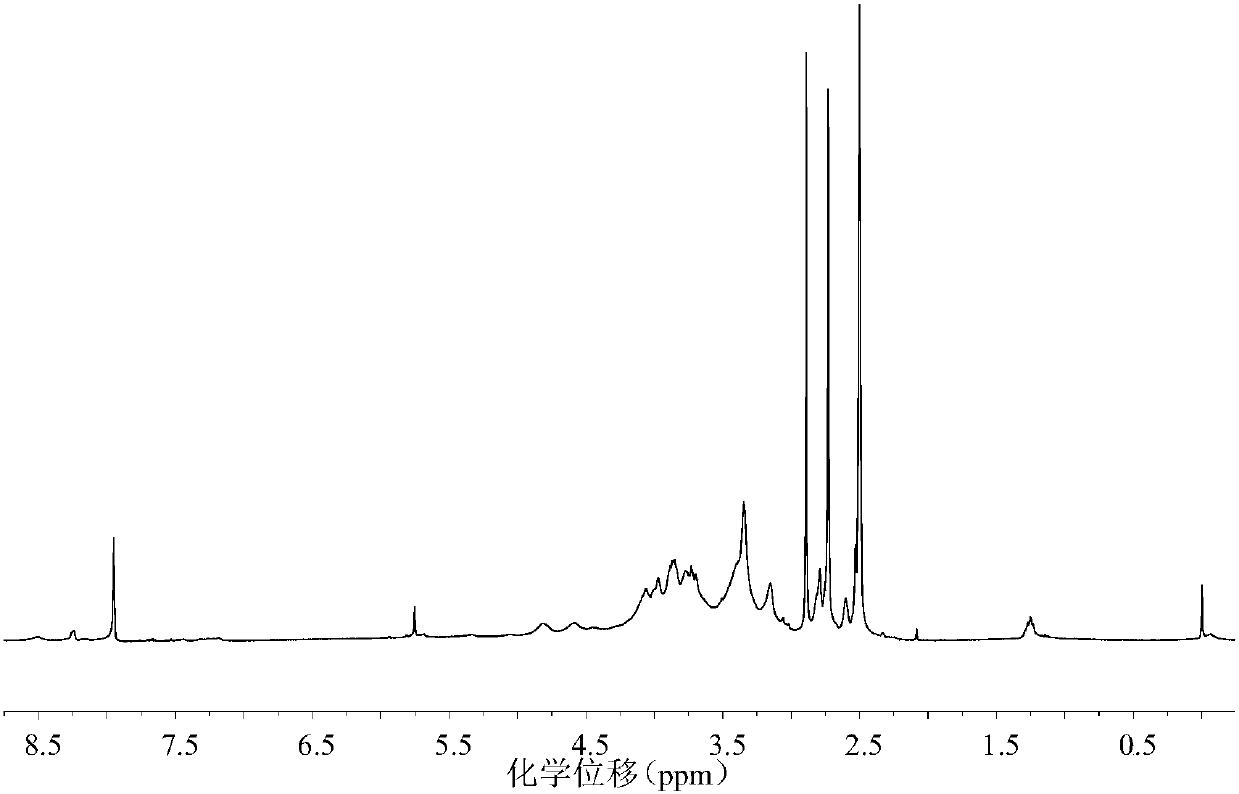

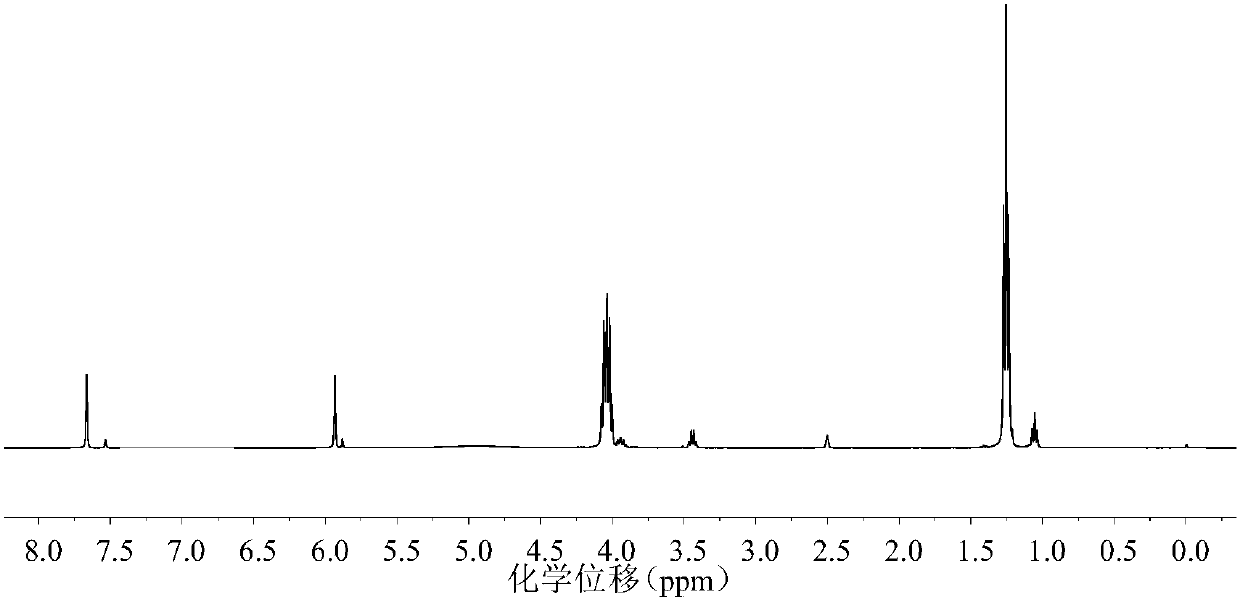

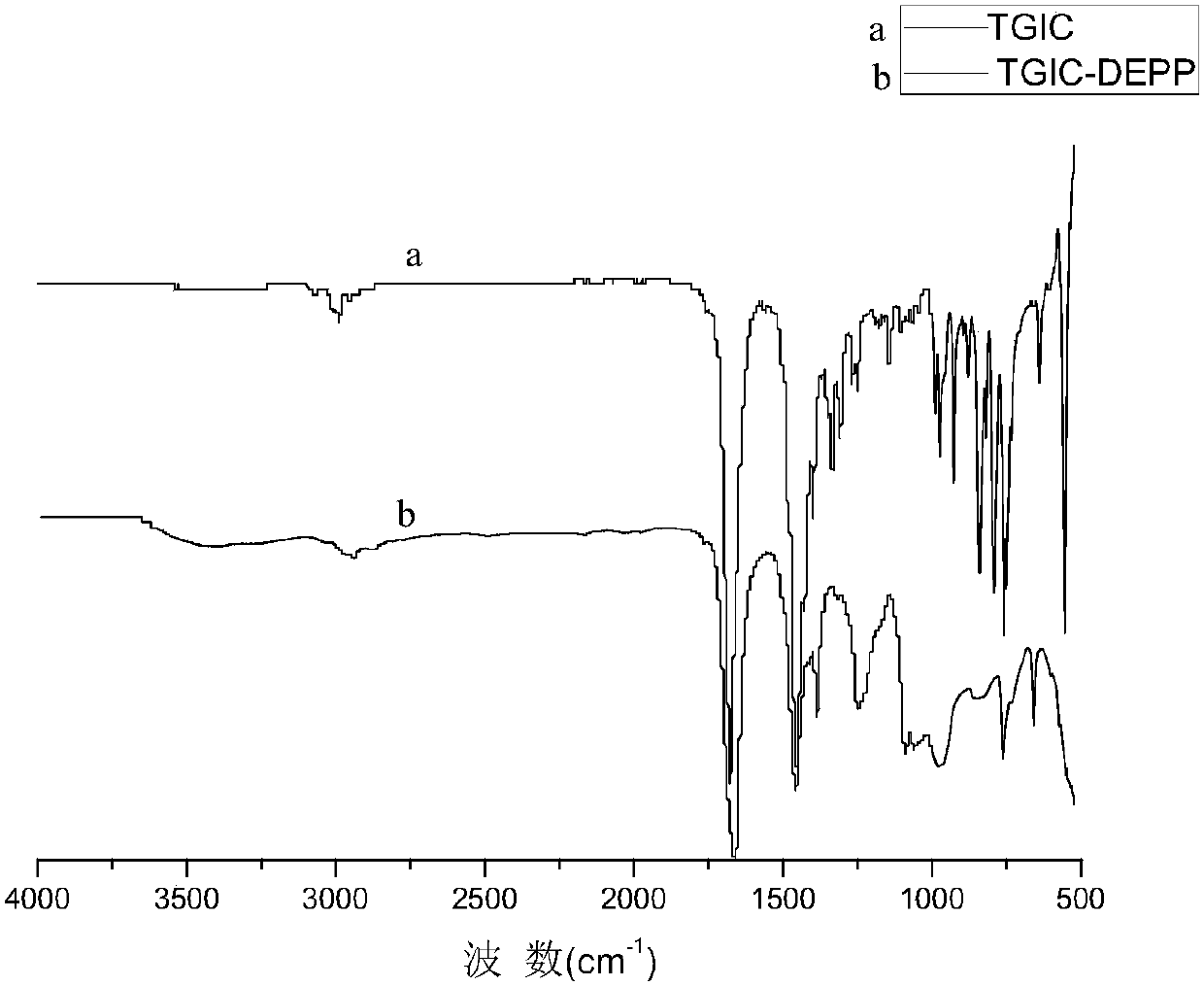

[0023] pass figure 1 Intumescent flame retardant TGIC-DEPP 1 H NMR spectrum and raw materials figure 2 It can be seen from the comparison figure 1 Intumescent flame retardant TGIC-DEPP 1 In the H NMR nuclear magnetic spectrum, the proton peaks of diethyl phosphite P-H at 7.66ppm and 5.93ppm disappeared, and -OCH in diethyl phosphite appeared 2 CH 3 Th...

Embodiment 2

[0026] Dissolve 11.8908g triglycidyl isocyanurate in 90ml dioxane and add it to a 150ml three-necked flask, then dissolve 16.56g diethyl phosphite in 20ml dioxane and add it to the above-mentioned three-necked flask. Under sub-stirring and condensing and reflux, the temperature was raised to 105°C, and the reaction was carried out for 15 hours. Then concentrated by rotary evaporation and precipitated with dichloromethane to obtain the crude product TGIC-DEPP. The crude product was centrifuged and washed three times with dichloromethane, and finally the product TGIC-DEPP was obtained.

Embodiment 3

[0028] Dissolve 8.9181g triglycidyl isocyanurate in 75ml N,N-dimethylformamide and add to a 150ml three-neck flask, then dissolve 4.14g diethyl phosphite in 15ml N,N-dimethylformamide and add To the above-mentioned three-necked flask, under nitrogen protection, magnetic stirring and reflux, the temperature was raised to 120° C., and the reaction was carried out for 10 h. Then concentrated by rotary evaporation and precipitated with dichloromethane to obtain the crude product TGIC-DEPP. The crude product was centrifuged and washed three times with dichloromethane, and finally the product TGIC-DEPP was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com