Liquid return circuit breaker valve

A technology of cut-off valve and valve core, which is used in mining equipment, earth-moving drilling, pillars/supports, etc., can solve problems such as leakage, and achieve the effect of prolonging service life and protecting biasing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

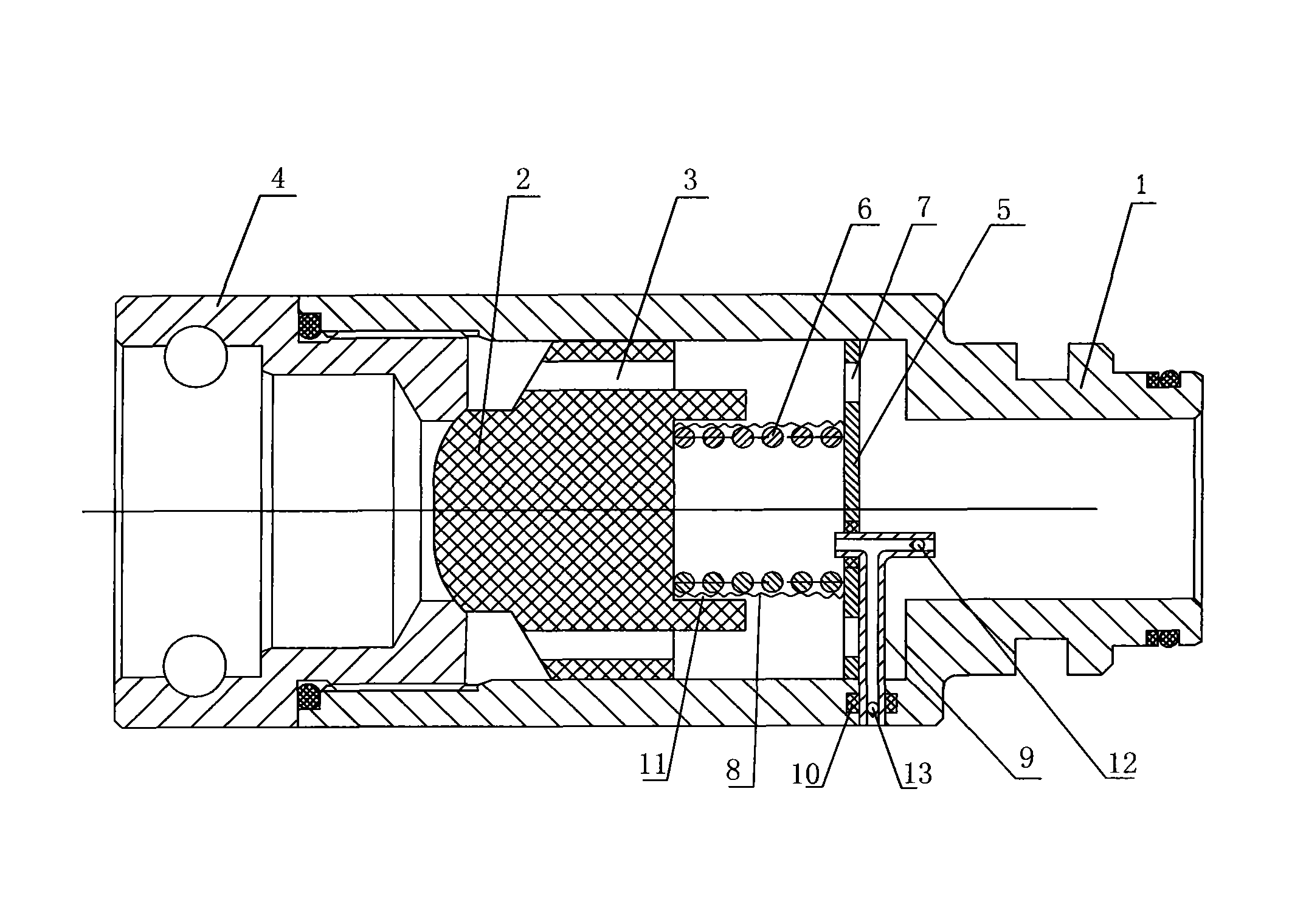

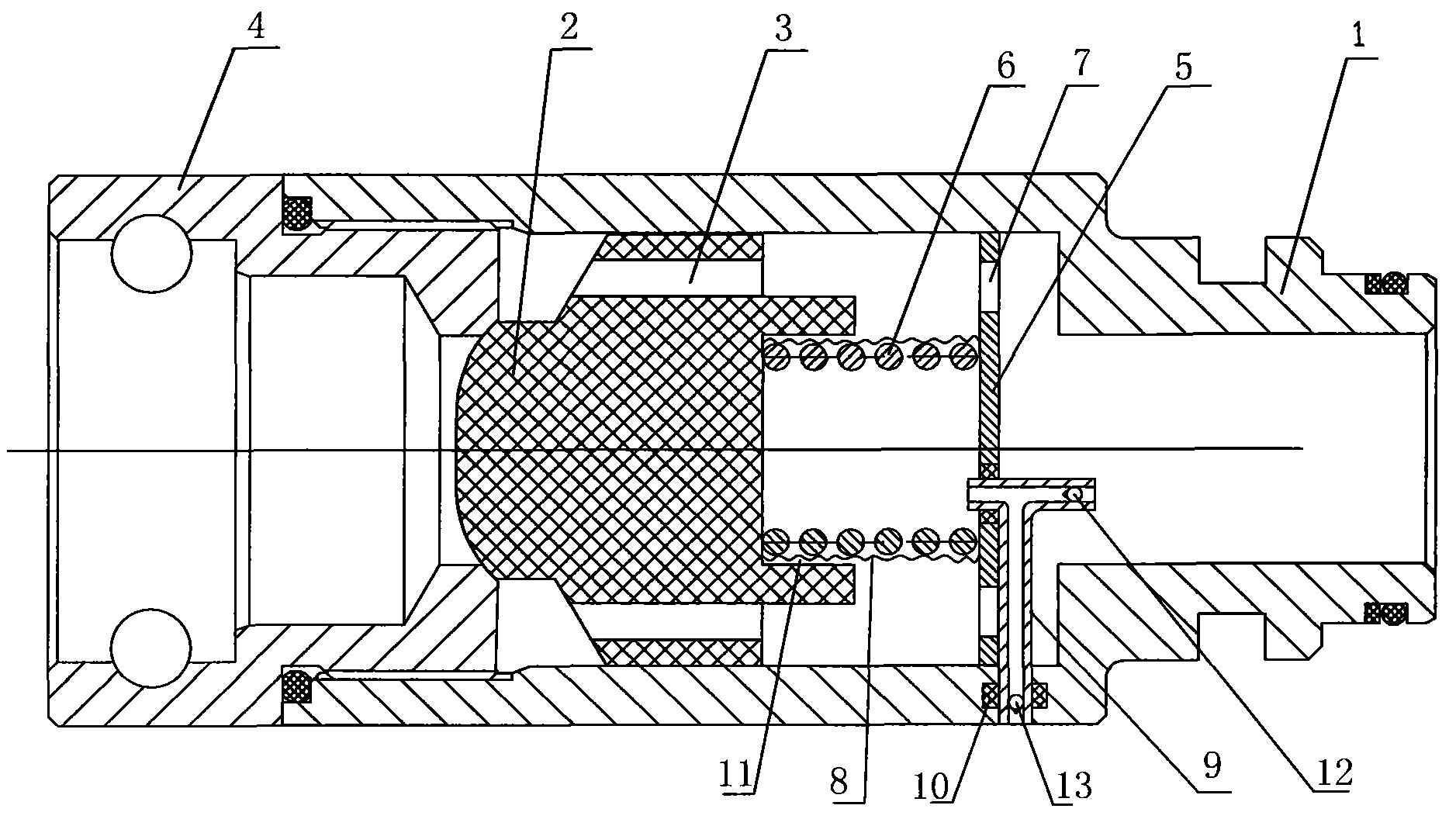

[0020] Such as figure 1 As shown, a liquid return cut-off valve in this embodiment includes a housing 1, and a cavity is formed in the housing 1;

[0021] A spool 2, the spool 2 is arranged in the through cavity, and the spool 2 is also provided with a liquid through hole 3 towards the tail of the spool;

[0022] A joint 4, the joint 4 is connected to one end of the housing 1 pointed to by the head of the valve core, and a through hole suitable for the insertion of the head of the valve core is formed in the joint 4, and the through hole of the joint 4 A contact seal is formed between the parts in contact with the head of the spool;

[0023] A biasing device, the biasing device is arranged at the tail of the valve core, and makes the head of the valve core close to the through hole by resisting the tail of the valve core;

[0024] A fixed plate 5, the fixed plate 5 is fixed in the through cavity at the tail of the valve core, and the fixed plate 5 is formed with a liquid hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com