Double-layer coiled welded pipe production line programmable logic controller (PLC) control cabinet

A double-layer coiled welded pipe and production line technology, applied in electrical program control, program control in sequence/logic controllers, metal processing, etc., can solve problems such as single function, reduce the influence of human factors, and achieve the effect of reasonable matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described with reference to the accompanying drawings and embodiments.

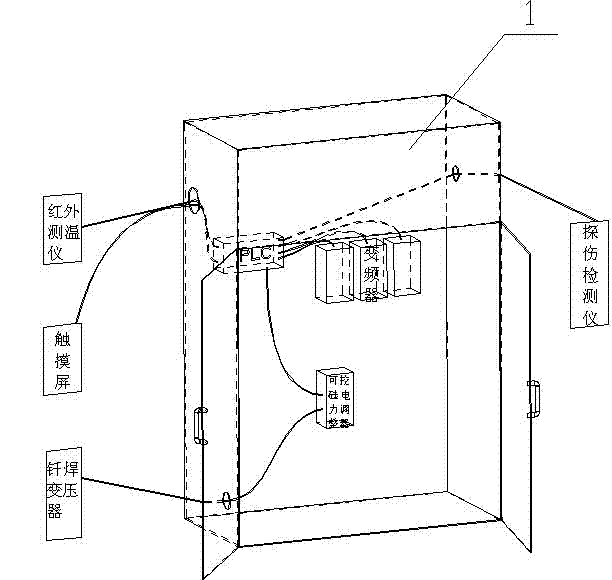

[0029] figure 1 In the middle; inside the control cabinet 1 are PLC controllers, frequency converters, and thyristor power regulators; outside the control cabinet 1 are infrared thermometers, touch screens, brazing transformers, and flaw detectors. Adjustment, infrared thermometer, touch screen, brazing transformer, flaw detector connection.

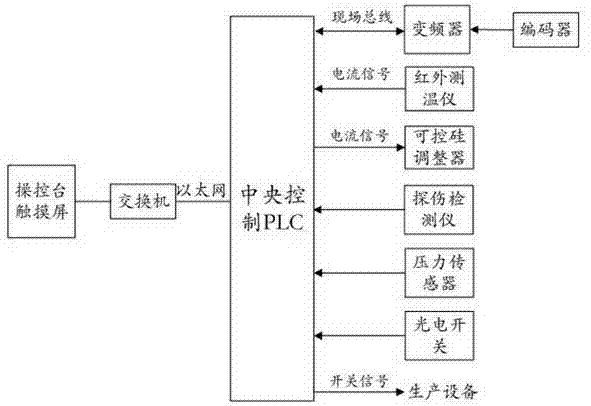

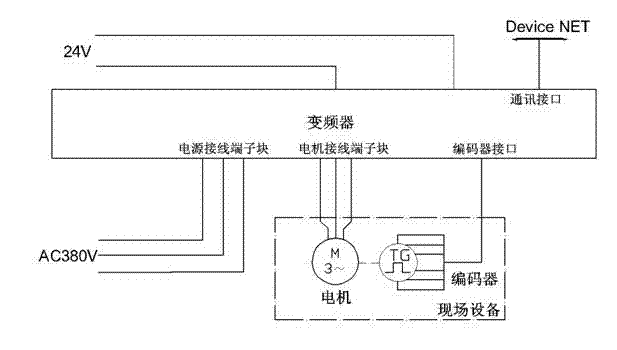

[0030] figure 2 Middle: The central control PLC, that is, the PLC controller is connected with encoders, touch screens, frequency converters, infrared thermometers, thyristor regulators, flaw detectors, pressure sensors, photoelectric switches, and production equipment, and is connected with corresponding electrical components Constitute the control system, the PLC controller collects the switch signals and analog signals collected from the production equipment, switches and monitoring devices, and outputs the switch s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com