Liquid cooling type radiator

A liquid cooling and radiator technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem that the cooling effect of the radiator cannot be uniform, the distribution of cooling liquid flow is uneven, and the cooling effect of the radiator is different. problem, to achieve the effect of small difference, equalization of flow, and improvement of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

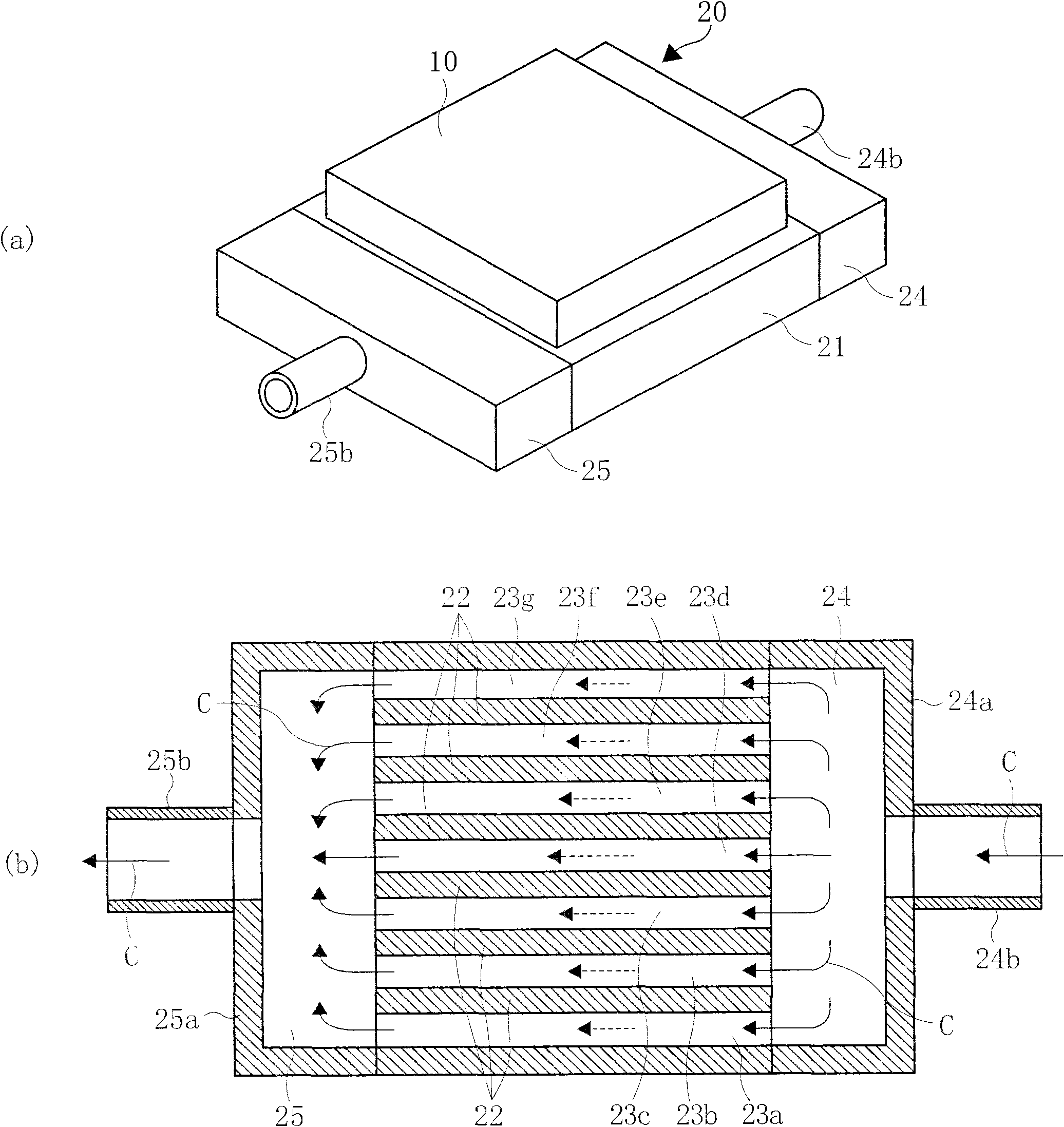

[0039] figure 1 represents the first embodiment of the present invention, figure 1 The configuration of the liquid cooling type radiator according to the first embodiment of the present invention is shown, wherein (a) is a perspective view showing the appearance, and (b) is a plan sectional view showing the internal configuration.

[0040] exist figure 1In the reference numeral 10, a modular semiconductor element as a heating element is bonded to the surface of a flat rectangular parallelepiped heat sink 20 made of a high thermal conductivity material such as copper or aluminum. The radiator 20 is provided with a radiator main body 21, and a plurality of fins 22 arranged in parallel at intervals therein form a plurality of cooling liquid flow passages 23 (23a to 23g). At both ends of the radiator main body 21 , an inflow header 24 through which the cooling liquid flows in and an outflow header 25 through which the cooling liquid flows out communicate with the cooling liqu...

no. 2 example

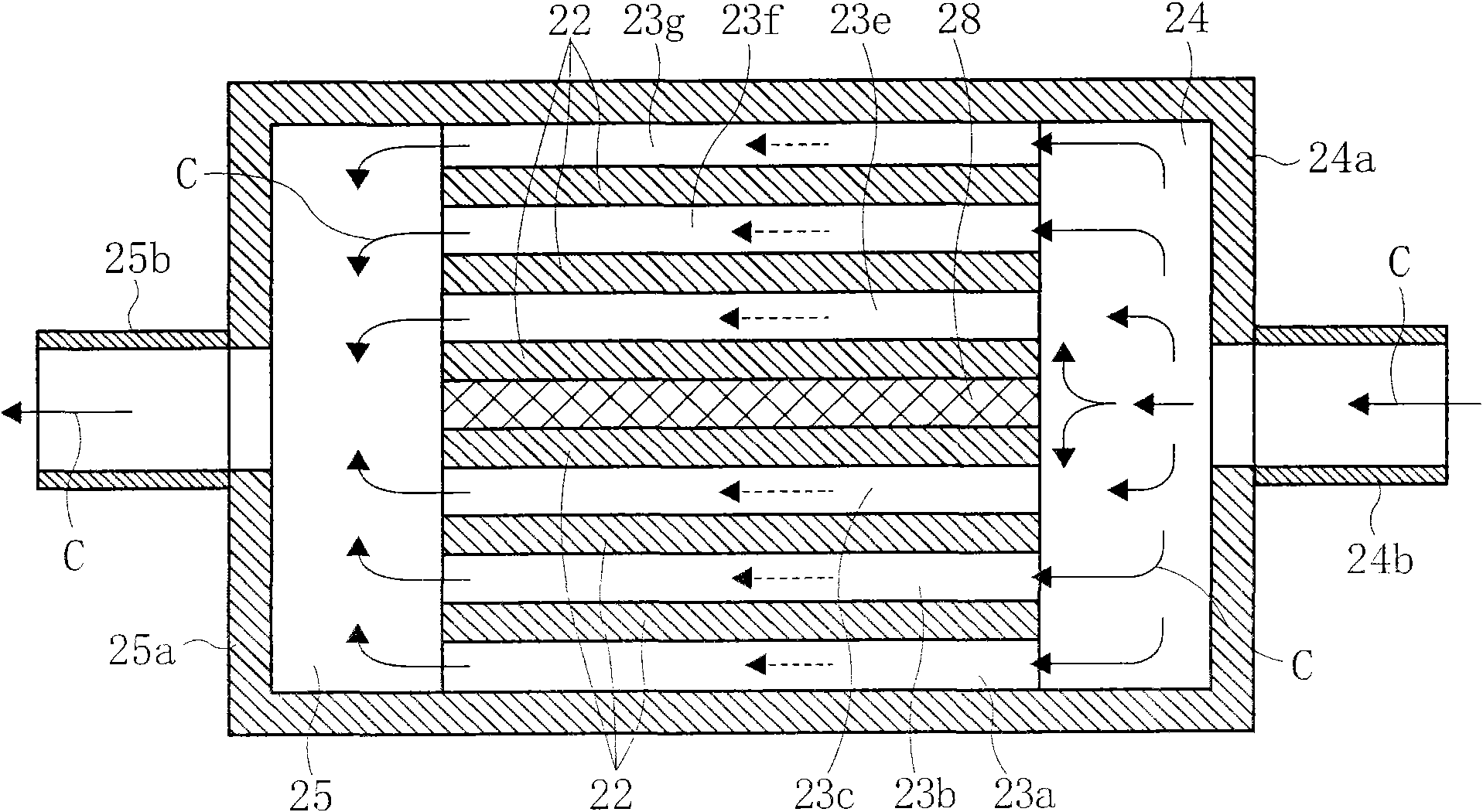

[0046] figure 2 Shows the second embodiment of the present invention. In the second embodiment, in the first embodiment, the flow rate of the cooling liquid circulation channel 23d located in the center is suppressed from being large, so that the flow rate of the cooling liquid circulating through each cooling liquid circulation channel is more equal.

[0047] The second example is figure 2 As shown, the closing body closes the cooling liquid circulation channel 23d in the center of the radiator main body 21 opposite to the cooling liquid inlet 24b and the cooling liquid outlet 25b, and serves as the cooling liquid flow control mechanism 28. Therefore, the cooling liquid from the cooling liquid inflow header 24 toward the central cooling liquid flow passage 23d is distributed and supplied to the cooling liquid flow passages on both sides, so the flow rates of the remaining cooling liquid flow passages 23a to 23c and 23e to 23g increase and the flow rates distributed as f...

no. 3 example

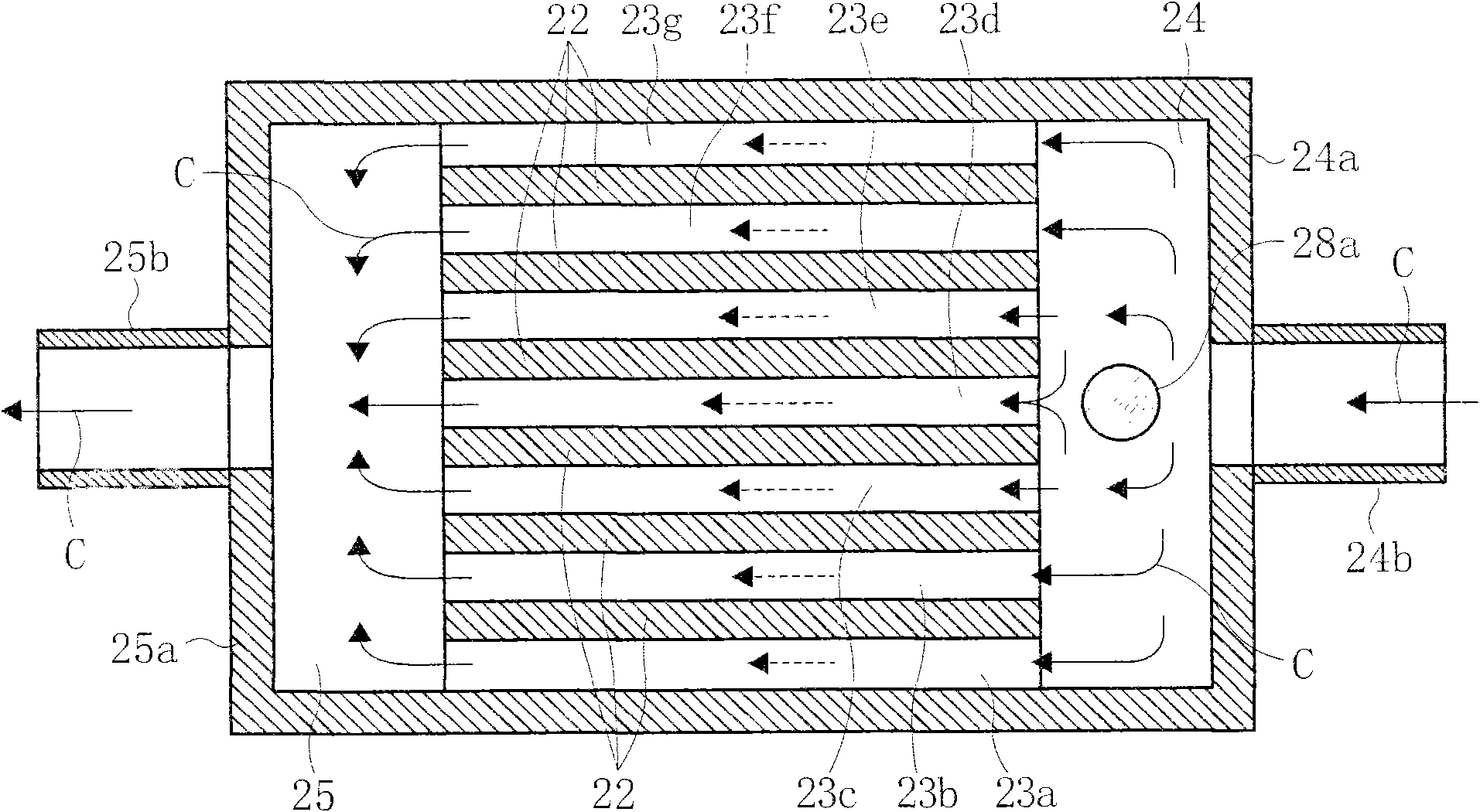

[0050] image 3 Shown is the third embodiment of the present invention.

[0051] In this third embodiment, between the cooling liquid inflow port 24b in the cooling liquid inflow header 24 and the central cooling liquid circulation channel 23d, a control protrusion 28a for guiding the cooling liquid flow from the center to both sides is provided, The inflow of the cooling liquid to the central cooling liquid circulation passage 23d is restricted.

[0052] The control protrusion 28a restricts the amount of cooling liquid flowing into the central cooling liquid flow path 23d, which usually has a large flow rate. Therefore, the flow rate of the central cooling liquid flow path 23d decreases, and the flow rates of the other cooling liquid flow paths on both sides Relatively increased, the flow distribution of the overall flow channel is as follows image 3 Homogenization is obtained as indicated by the dotted arrow. Therefore, the uniformity of the cooling effect of the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com