Valve body assembly

A component and valve body technology, applied in the direction of lift valve, valve detail, multi-way valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The terms front and back have been chosen in a purely conventional and arbitrary manner to simplify the description of the valves, but without prejudice to the orientation of the valves in use. In this case, front and rear are relative to the plane of the seal of the valve shutter, and rear is the end of the recirculation exhaust gas channel leading to the heat exchanger.

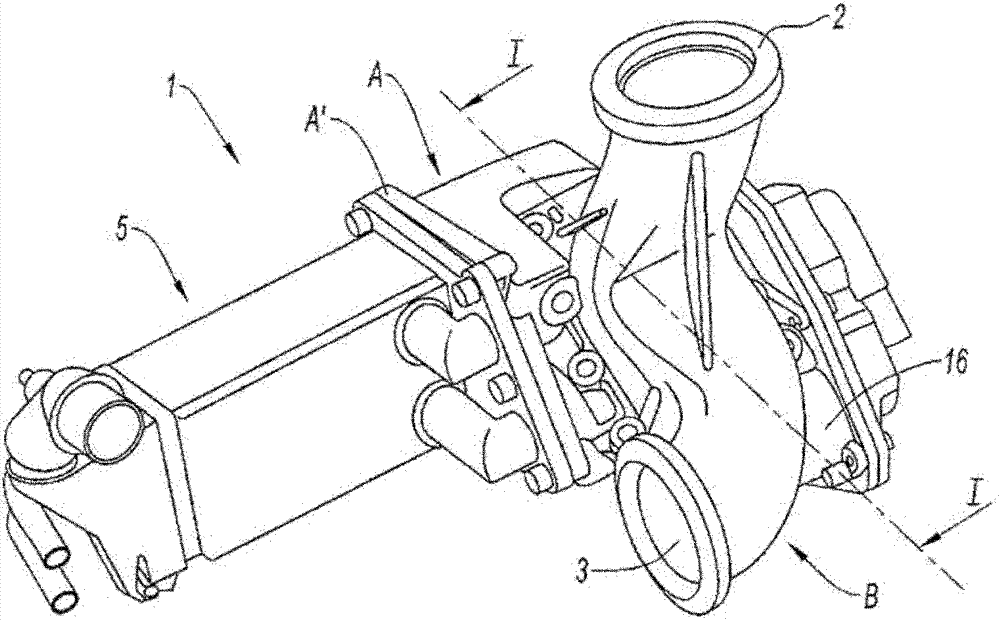

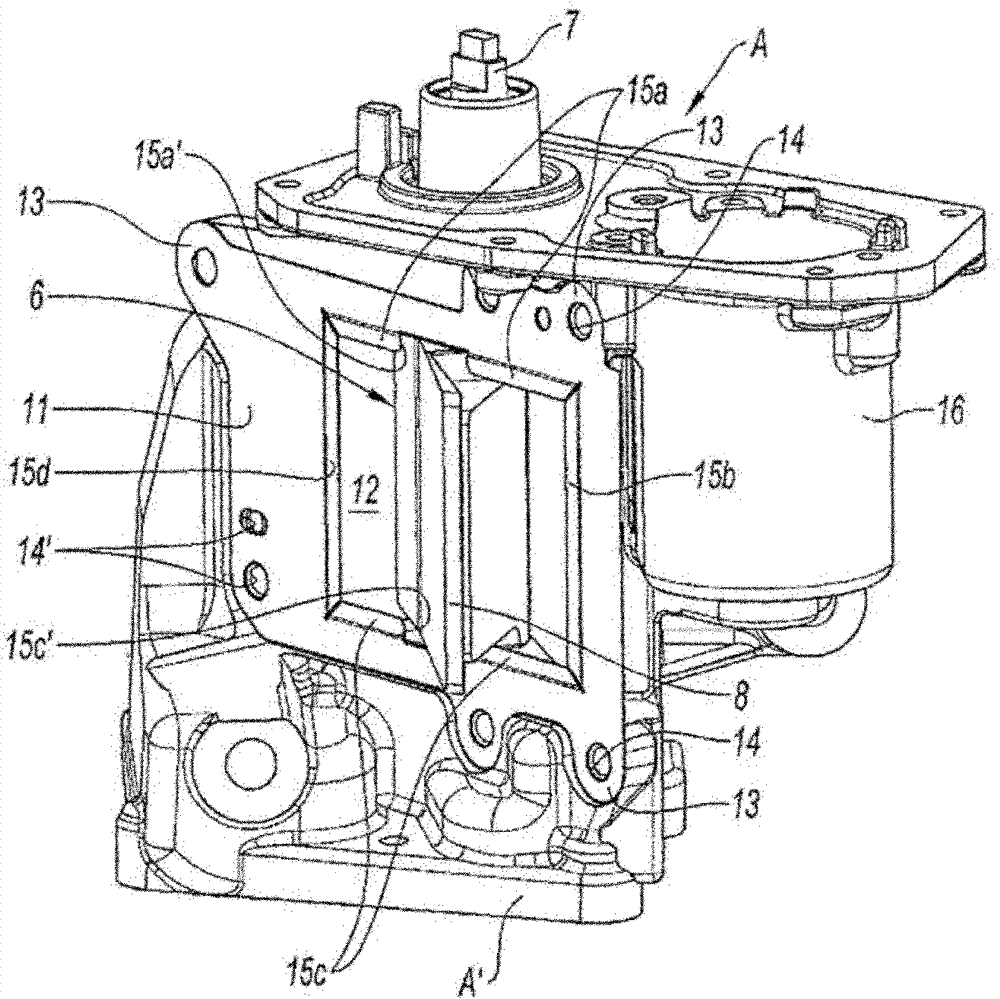

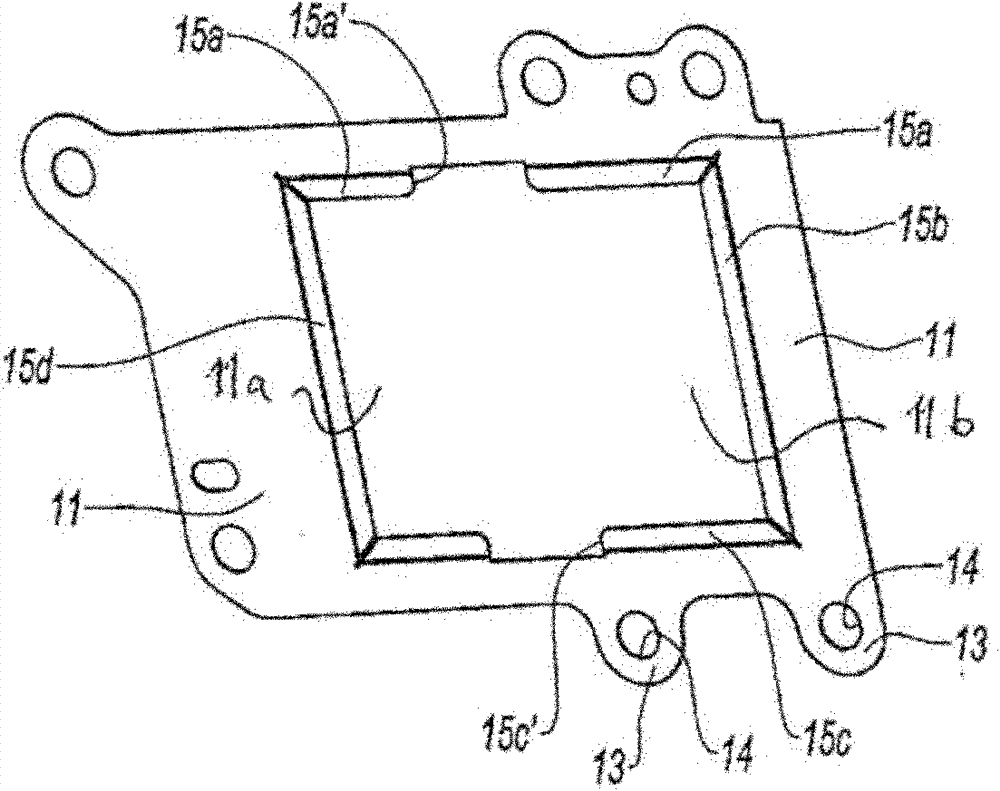

[0041] functionally, see figure 1 , a so-called "three-way" valve 1 comprising an inlet channel 2 for gas entering the valve, a first gas outlet channel 3 and a second gas outlet channel 4 . Structurally, the valve 1 comprises a valve body A, to which an exhaust pipe B is mounted and fixed;

[0042] It should be noted that, by definition, a valve is a component comprising a valve shutter and a plurality of channels, while the valve body is a structural element of the valve supporting the valve shutter 6 .

[0043] The first outlet channel 3 is a direct exhaust gas outlet channel; it is called exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com