Horizontal swing type inter-plant weeding device

A horizontal swing and inter-plant technology, which is applied in the field of agricultural robots, can solve the problems of damage to crops, high prices, and lack of mature inter-plant weeding tools, and achieve the effect of reducing precision requirements and reducing system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

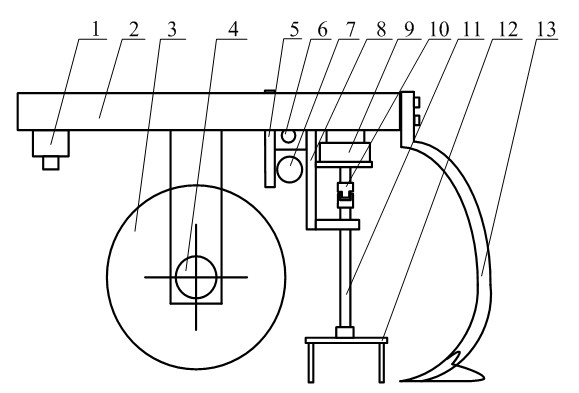

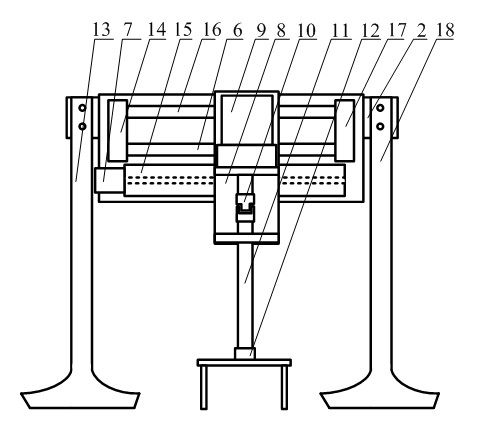

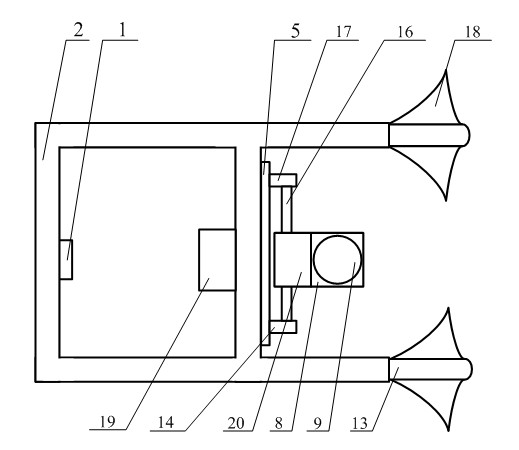

[0023] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0024] Such as Figure 1 to Figure 6 As shown, the present invention discloses a horizontal weeding device between rows, including a car body, the car body includes a main frame 2 and a depth-gauge wheel 3, wherein it also includes a horizontal weeding structure arranged on the main frame, a weeding Weeding components, inter-row weeding structure, vision and control system, the weeding weeding structure makes the weeding parts enter the inter-plant area through swaying motion for weeding, and the inter-row weeding structure uses a pair of wing shovels to shovel into the soil for weeding, vision and control system The crops are identified, the plant protection area and the inter-row weeding area are determined, and the weeding structure and the inter-row weeding structure are controlled to weed in the inter-row weeding area. The main frame 2 provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com