Three-dimensional punching equipment for disposable hygienic material and punching method thereof

A three-dimensional, hygienic material technology, which is applied in the cutting of textile materials, textiles and papermaking, and fabric surface trimming, can solve the problems of rolling, skin feeling uncomfortable, and small liquid storage capacity of perforated non-woven fabrics, and achieve urine The effect of large liquid volume, reduced contact area, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

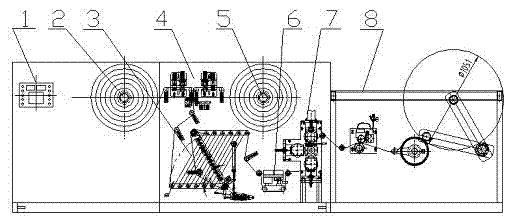

[0019] Embodiment 1: with reference to attached Figure 1-7 . Three-dimensional three-dimensional punching equipment for disposable sanitary materials, which includes PLC controller 1, first unwinding material roller 2, tension control mechanism 3, pressing material cutting and splicing mechanism 4, second unwinding material roller 5, encoder 6, Three-dimensional three-dimensional punching mechanism 7 and winding mechanism 8,

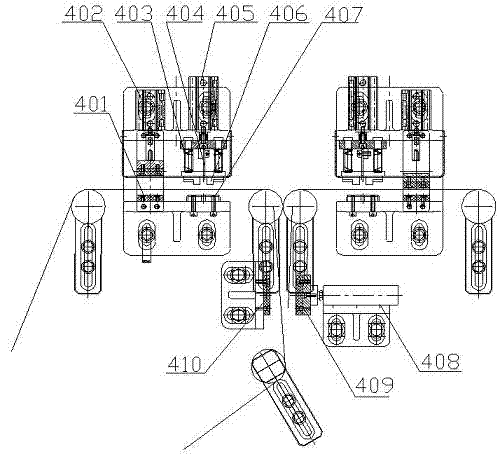

[0020] The pressing material cutting and splicing mechanism 4 is composed of two sets of pressing material cutting devices with the same structure and a set of splicing devices. The cylinder 405 and the groove cutter plate 407 are formed, the pressing plate 401 is composed of an upper plate and a lower plate, the upper plate is connected with the pressing cylinder 402, the lower plate is fixed on the frame and is opposite to the upper plate surface; the cutting cylinder 405 piston The end face is connected with the cutter press plate in the elastic cu...

Embodiment 2

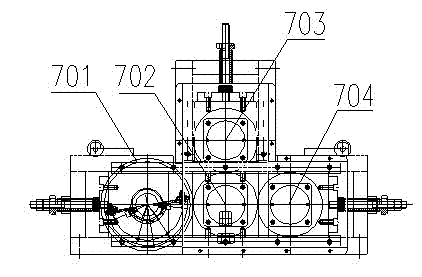

[0025] Embodiment 2: On the basis of Embodiment 1, the perforated concave roller 702 and the perforated convex roller 703 are distributed up and down, that is, the perforated concave roller 702 is on the bottom and the perforated convex roller 703 is on the top, or the perforated concave roller 702 is on, punching convex roll 703 is down.

Embodiment 3

[0026] Embodiment 3: on the basis of embodiment 1, with reference to appended Figure 8 . Three-dimensional three-dimensional punching method for disposable hygienic materials, (1) the non-woven fabric splicing cloth head on the second unwinding material roller 5 is glued with double-sided adhesive tape and is located on the fixing plate 410 of the pressing device of the pressing cutting and splicing mechanism 4 Standby with the movable plate 409, at this time, the pressure cylinder 402 in the second pressure cutting device compresses the spare non-woven fabric coil through the pressure plate 401 under the PLC command; The non-woven fabric roll enters the three-dimensional punching mechanism 7 through the pressing cutting and splicing mechanism 4, the tension control mechanism 3, and the knitting device 6, and then passes through the traction roller 704 to the convex-concave extrusion of the punching concave roller 702 and the punching convex roller 703. After punching both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com