Final-stage moving blade of wet cooling steam turbine

A technology for steam turbines and moving blades, which is applied to machines/engines, supporting elements of blades, mechanical equipment, etc., can solve the problems of uneven force on the arched shroud, affecting the safe and normal operation of the steam turbine, and difficult to accurately calculate the frequency. The effect of high economy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] All features disclosed in this specification, except mutually exclusive features, can be combined in any way. Any feature disclosed in this specification, unless specifically stated, can be replaced by other equivalent or similar purpose alternative features. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

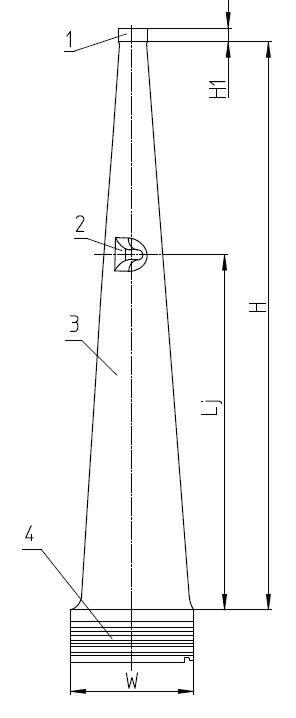

[0034] The design carrier of this moving blade is a wet-cooled double-exhaust 220MW steam turbine. The most suitable design back pressure of this machine is 8kPa. Within this design back pressure range, the structure of the last-stage moving blade determined by the final scheme can be found in figure 1 . The blade is made of suitable alloy steel blade and rotor material. The moving blade is composed of 4 parts, namely: shroud 1, damping boss reinforcement 2, blade body 3, and blade root 4. All parts are integrally manufactured with the same high-strength alloy steel.

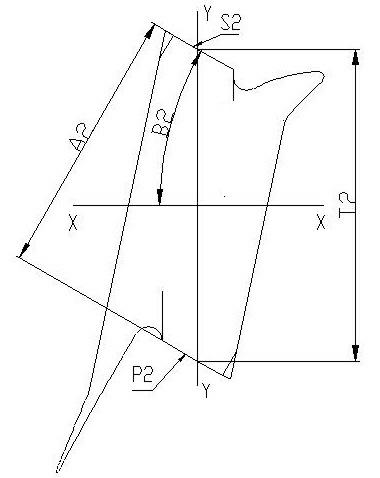

[0035] (1) Blade bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com