Large two-stroke diesel engine with exhaust gas recirculation system

An exhaust gas recirculation and two-stroke technology, which is applied in the direction of exhaust gas recirculation, engine components, engine control, etc., can solve the problems of expensive blower motors and increased loads, and achieve multi-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

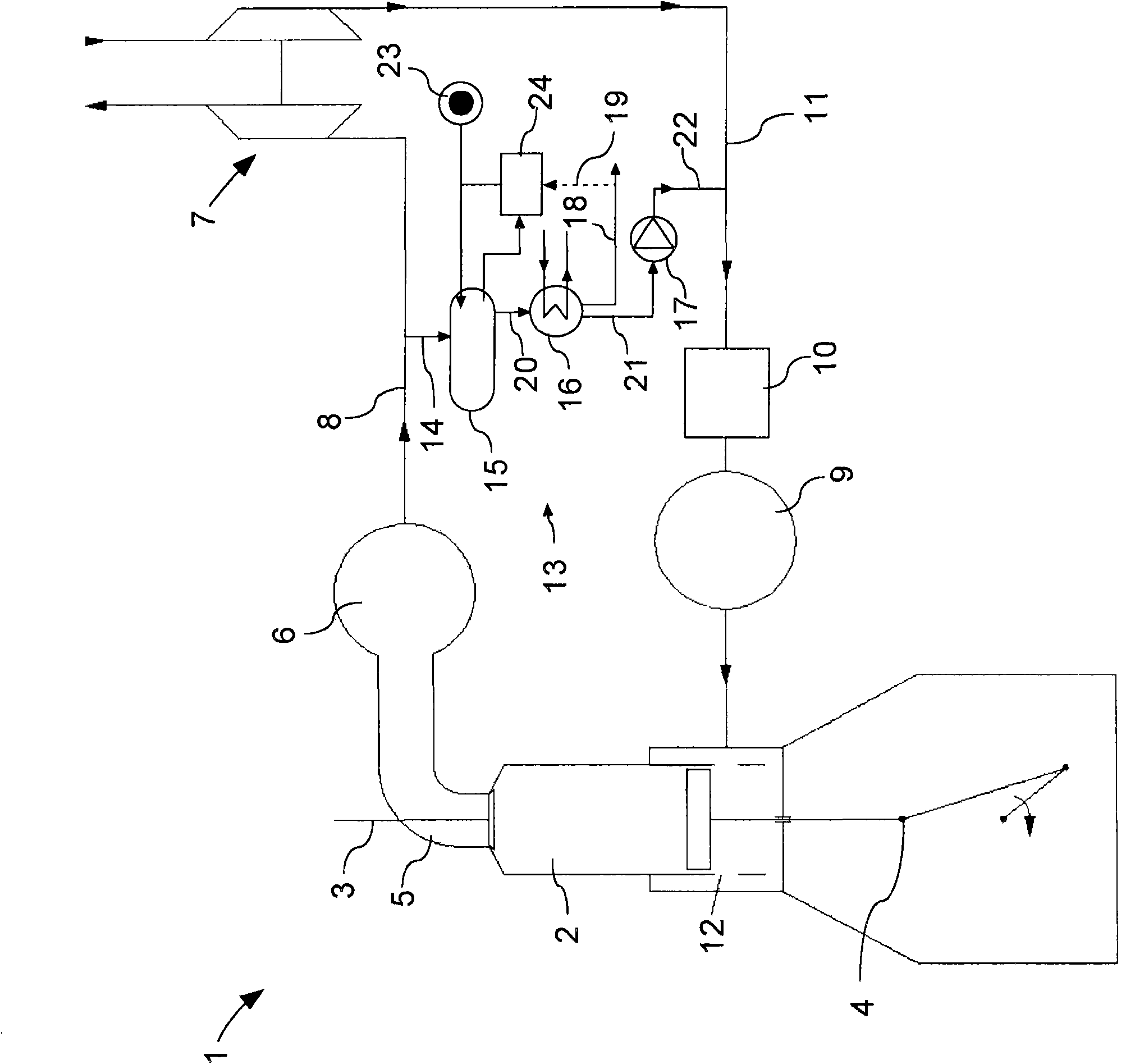

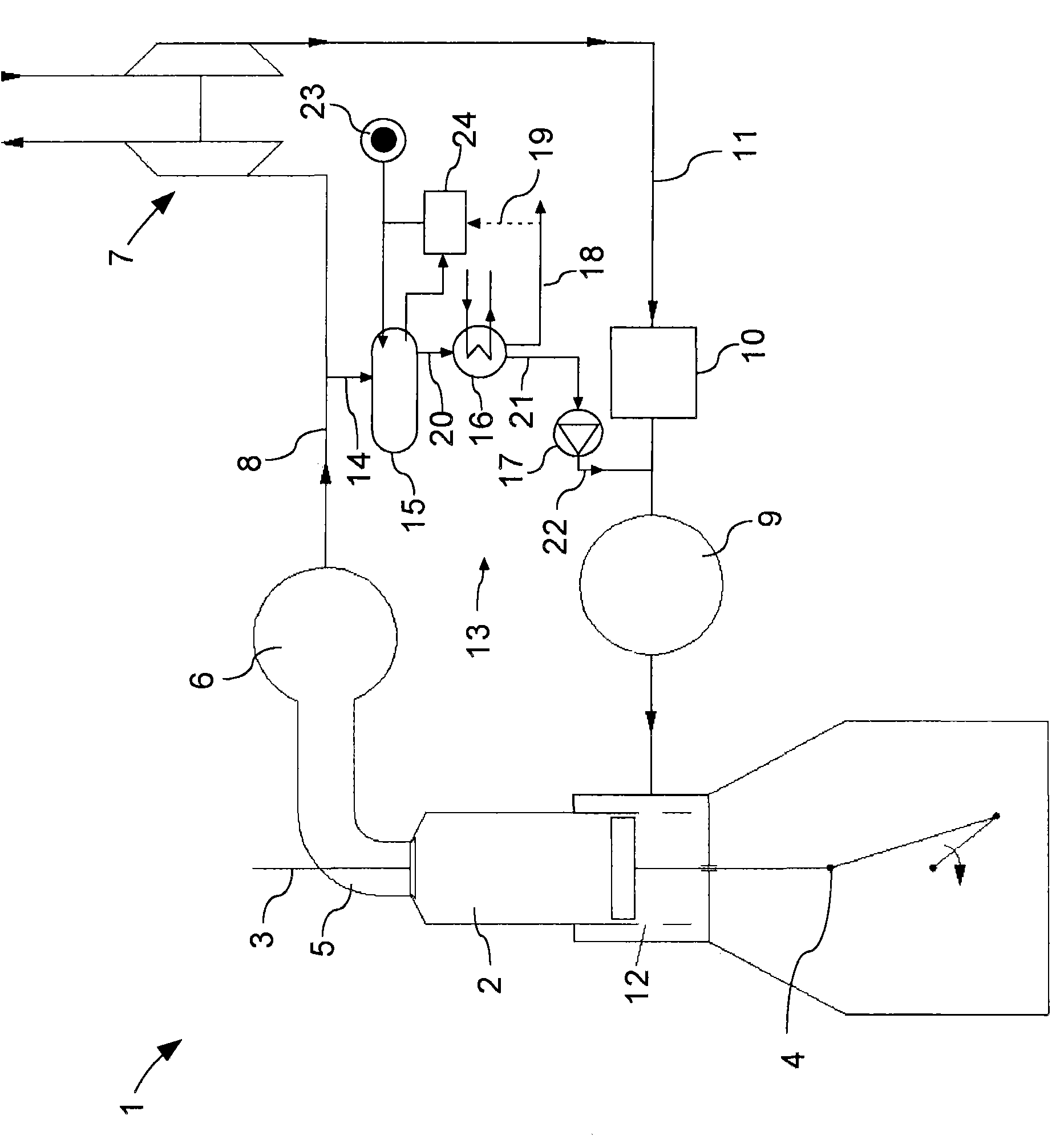

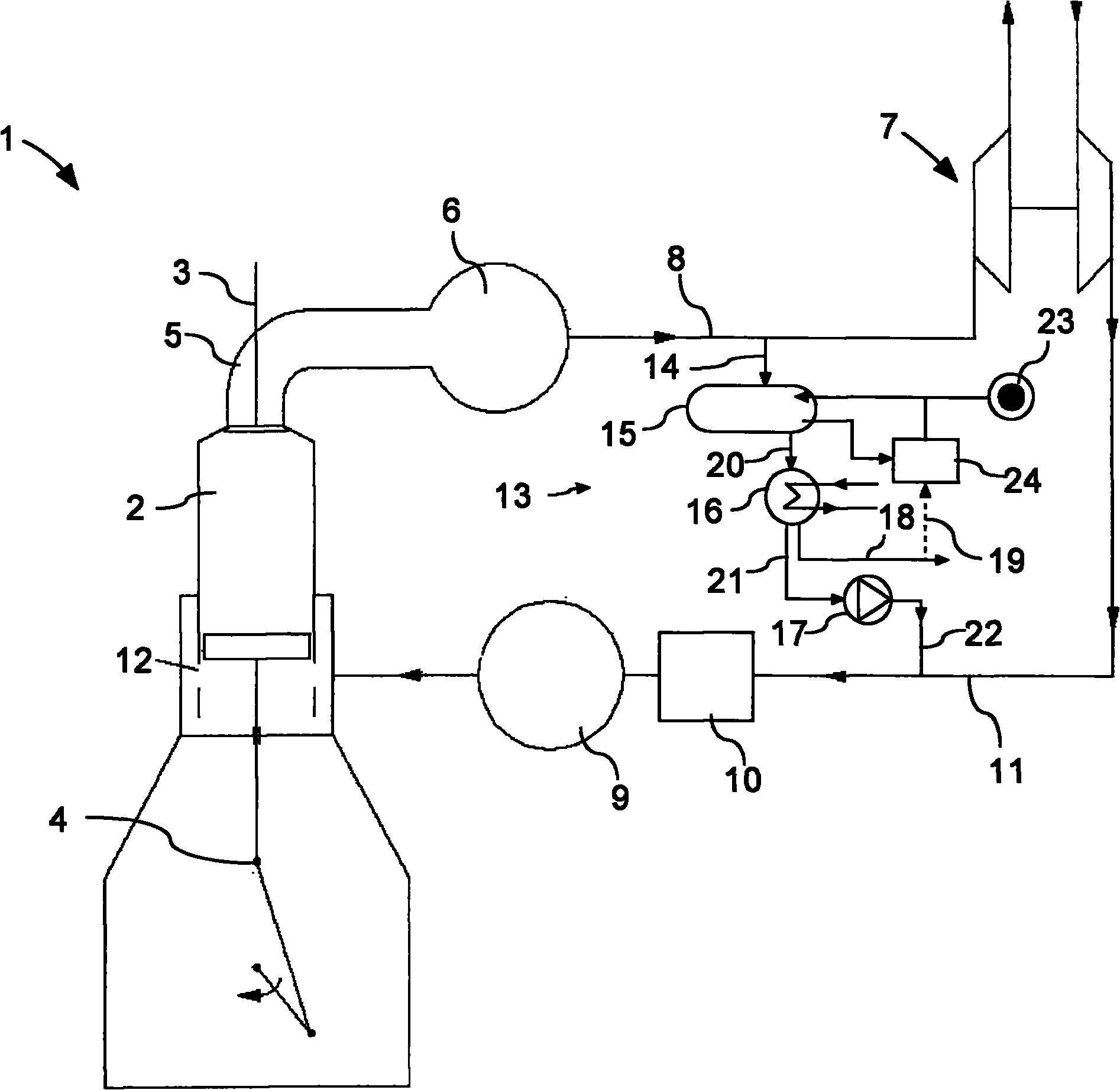

[0039] Hereinafter, a detailed description of a crosshead type large turbocharged two-stroke diesel engine according to the present invention and a method for operating the crosshead type large turbocharged two-stroke diesel engine will be described through exemplary embodiments.

[0040] The structure and operation of large turbocharged diesel engines of the crosshead type is also known and no further explanation should be required herein. Further details regarding the operation of the exhaust system are provided below.

[0041] figure 1 A first exemplary embodiment of a large two-stroke diesel engine 1 according to the invention is shown. The engine 1 may for example be used as a main engine in an ocean-going vessel, or as a stationary engine for operating a generator in a power station. The total output of the engine may, for example, range from 5,000 to 110,000 kW.

[0042] The engine is provided with a plurality of cylinders 2 arranged side by side with each other alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com