Exhaust treatment devices for diesel engines

A technology for exhaust treatment devices and diesel engines, applied to exhaust devices, engine components, machines/engines, etc., can solve problems such as not being able to fully improve PM capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

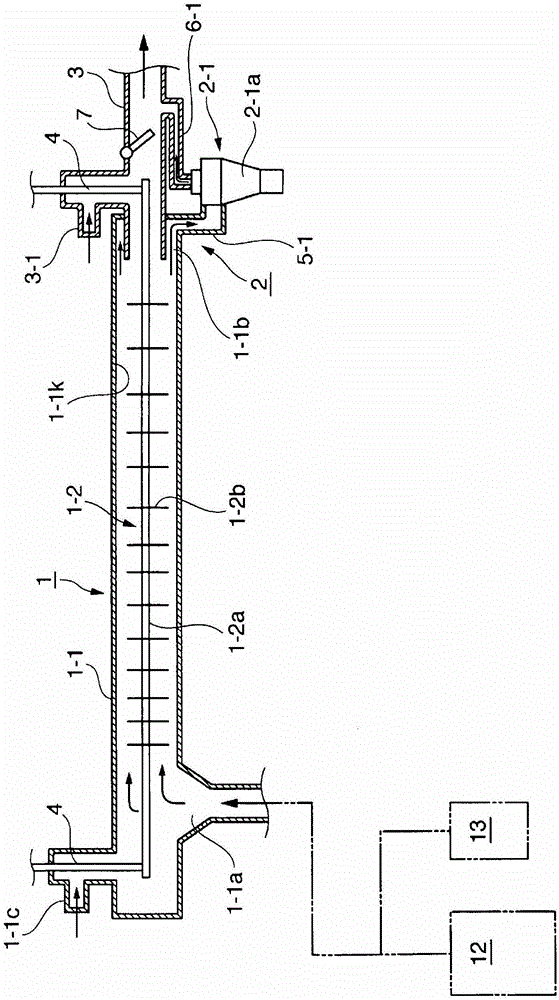

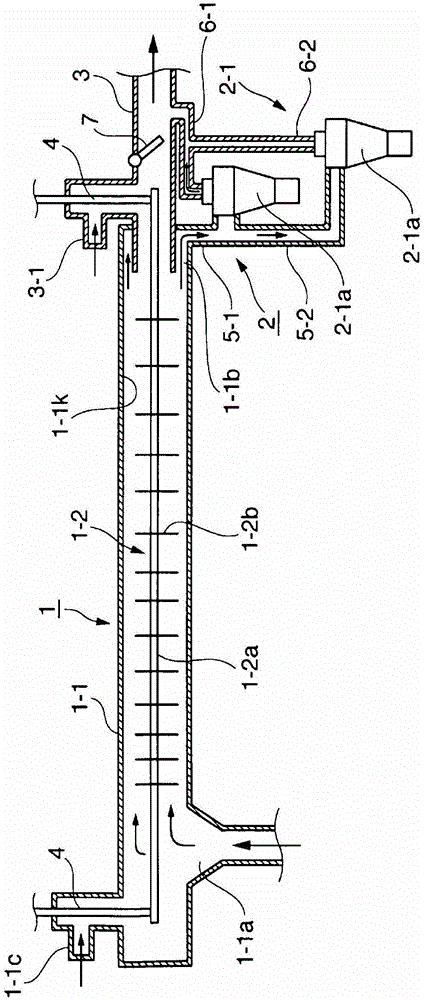

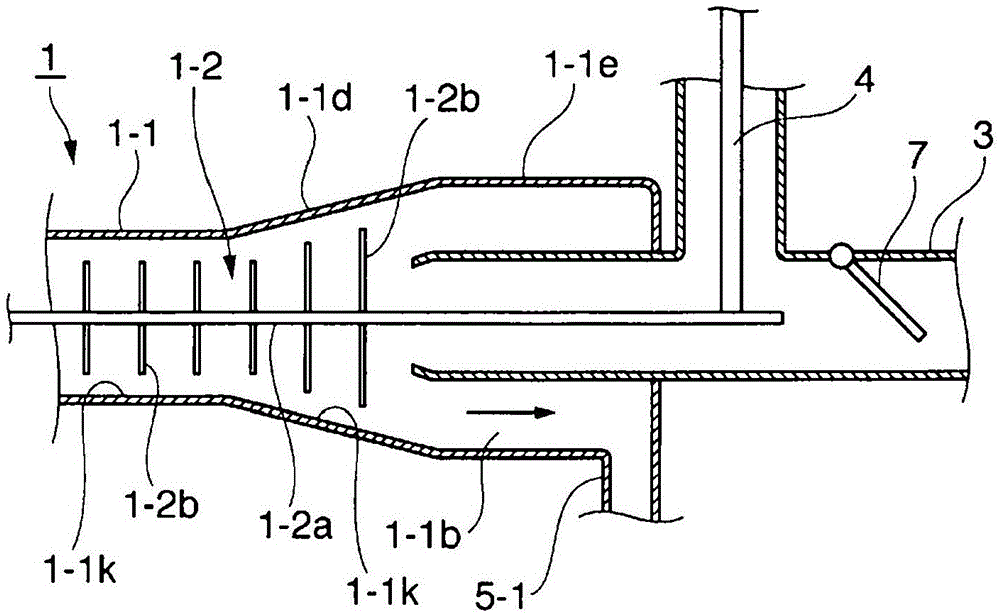

[0061] in figure 1 The exhaust gas treatment device for a large displacement diesel engine that uses low-quality fuel below heavy oil as shown in the device as the first embodiment of the present invention is roughly divided and includes a tubular collection part 1 constituting an electric dust collection mechanism And the separation and collection unit 2 constituting the separation and collection mechanism, and the tubular collection unit 1 provided to collect PM particles is equipped with a collection tube 1-having a predetermined length and a collection wall surface 1-1k constituting a dust collecting electrode. 1. And discharge electrodes 1-2 that charge PM contained in exhaust gas. On the collecting pipe 1-1 constituting the dust collecting electrode, there is an exhaust gas inlet 1-1a at the end of the upstream side (diesel engine side), and the PM low concentration exhaust is connected and installed near the axis of the downstream end. The gas outlet pipe 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com