Elastic support of lampshade of paper lamp and manufacturing method

A technology for elastic brackets and lampshades, which is applied in the direction of lampshades, lighting devices, lighting device components, etc., can solve problems such as high production costs, easy falling off of steel wire brackets, complicated manufacturing process of steel wire brackets and ring iron sheets, etc., to achieve Easy to fix, not easy to fall off, stable and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

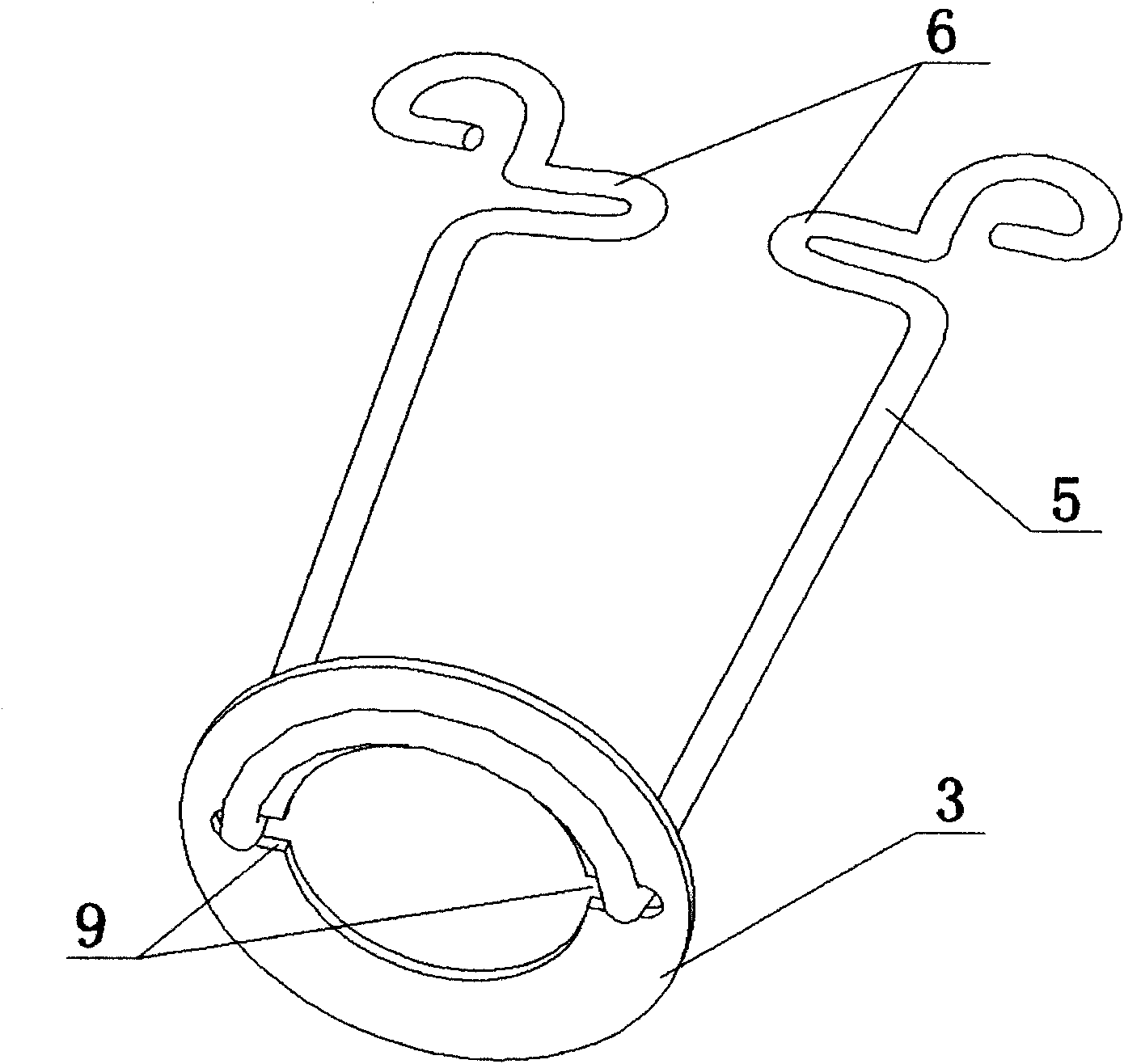

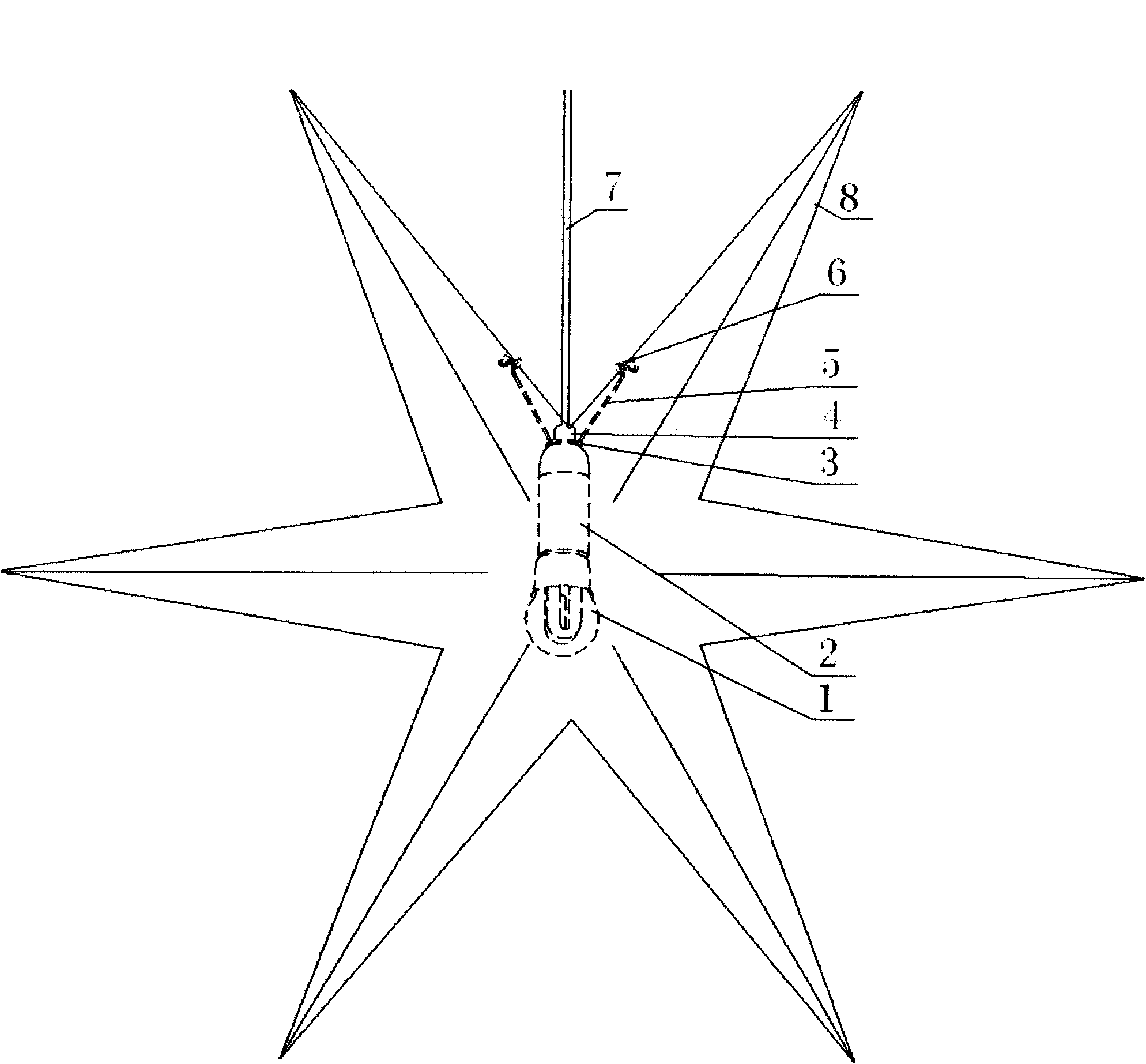

[0018] Embodiment 1: as figure 1 As shown, a paper lamp lampshade elastic support, it includes an annular iron sheet 3 and an elastic steel wire support 5, two notches 9 for fixing steel wires are arranged symmetrically along the inner edge of the annular iron sheet 3, and the elastic steel wire support 5 is folded by a steel wire It is bent into a 180° arc in the middle of the steel wire, and then folded with the two endpoints of the arc as inflection points. The folding angle is 90° from the arc plane, and the two ends of the steel wire are respectively bent inward to Hang the lug 6 of the lampshade, and the elastic steel wire support 5 is installed in the notch 9 of the fixed steel wire and makes the arc section of the steel wire close to the annular iron sheet 3.

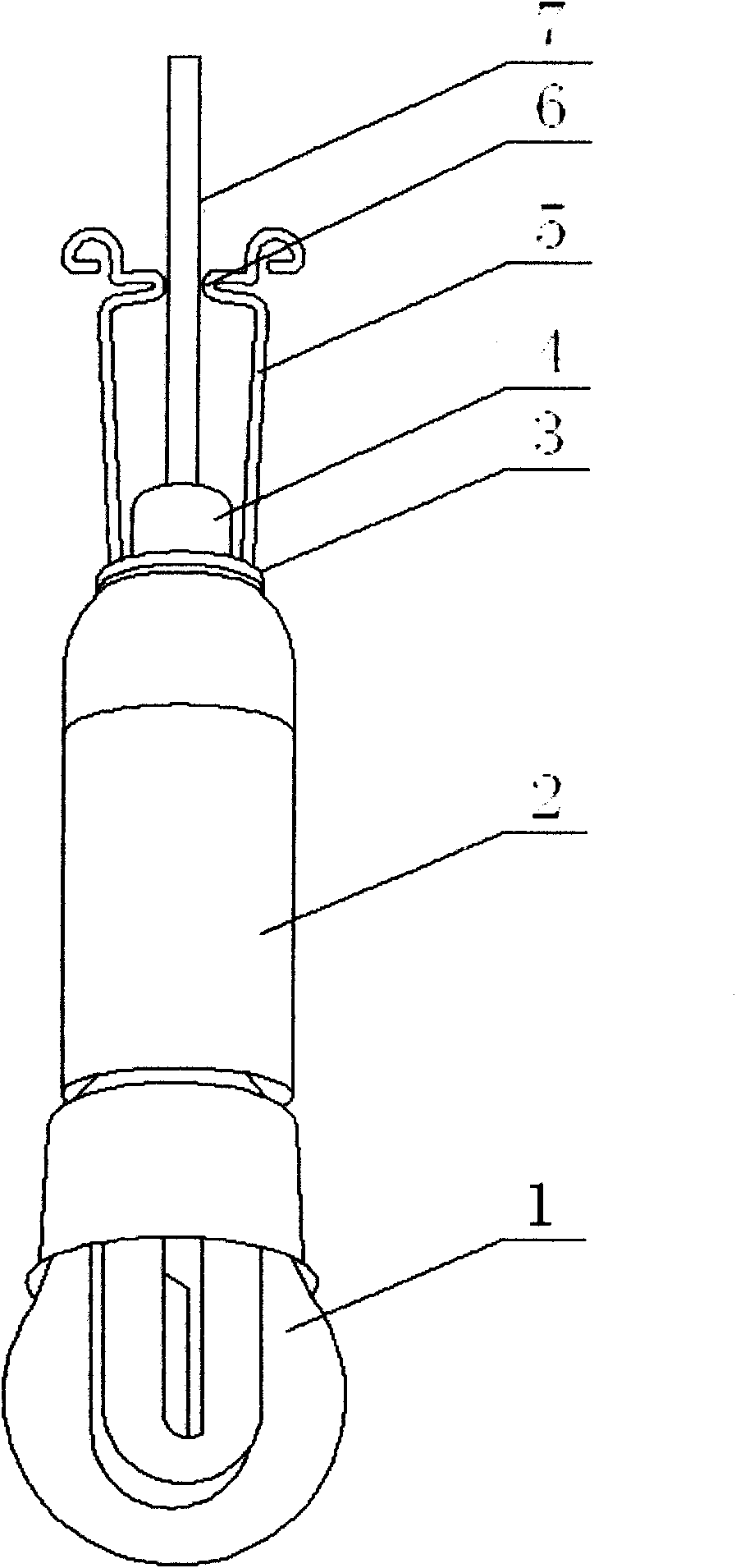

[0019] Such as figure 2 As shown, it is a schematic diagram of the installation of the elastic bracket of the lampshade of the paper lamp, the lamp holder and the bulb. The bulb 1 is installed under the lamp h...

Embodiment 2

[0021] Embodiment 2: The manufacturing method of the elastic support of the lampshade of the paper lamp, which includes the following steps: 1) stamping the iron plate into an annular iron sheet with two symmetrical fixed steel wire notches along the inner edge; 2) selecting a diameter of 1-1.2mm The 65# manganese steel wire is made according to the size of the section; 3) The middle section of the steel wire is bent into a 180° arc, and then the two ends of the arc are used as the folding points to fold the steel wire. The folding angle is 90° from the arc plane. Both ends are respectively bent inward to form the lampshade hanging lug and the top end to turn back to make an elastic steel wire support; 4) Assemble the elastic steel wire support to the ring iron sheet; 5) Manually operate the shaping; 6) Add tempering and electroplating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap