Novel high-temperature solar vacuum heat-gathering pipe sealed by ceramic copper cladding

A solar energy and heat collecting tube technology, applied in the field of solar energy technology utilization, can solve the problems of shortening the length of the corrugated tube, complicated process, easy to break, etc., and achieve the effects of reducing the difficulty and cost of the process, having broad application prospects and avoiding the complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

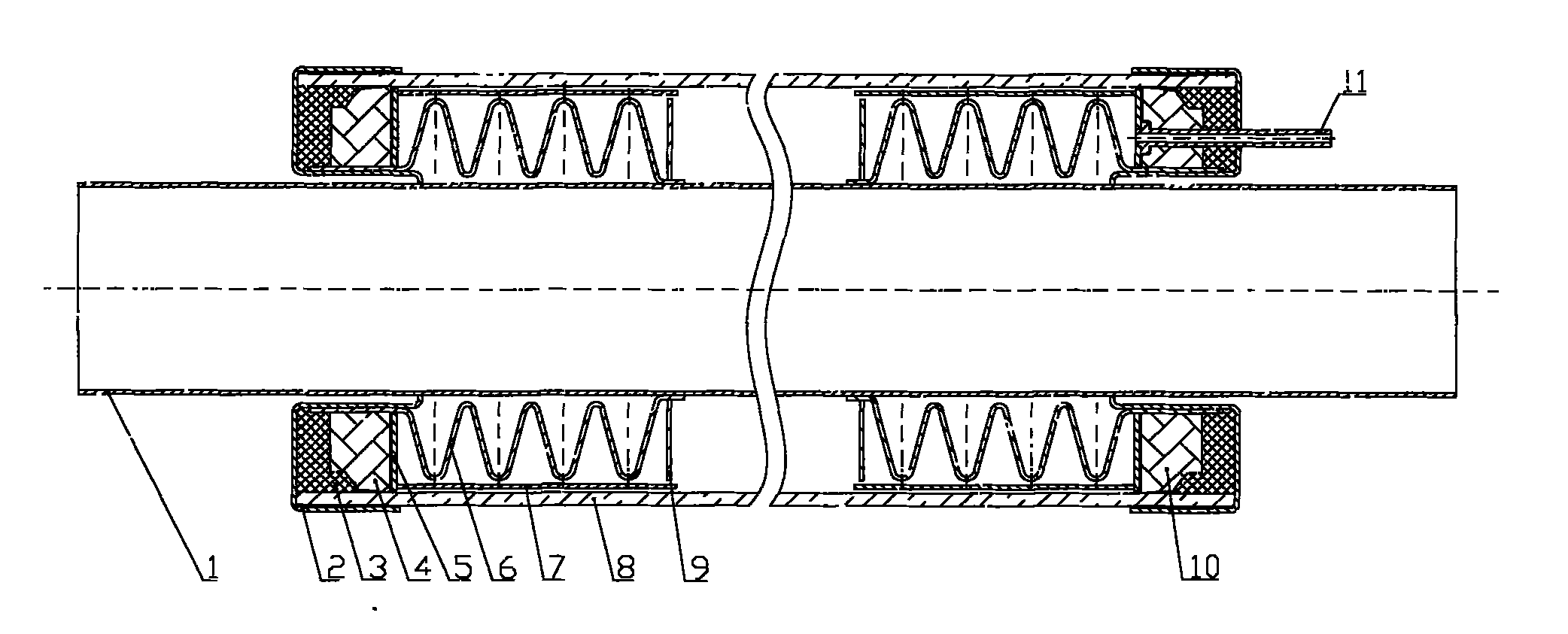

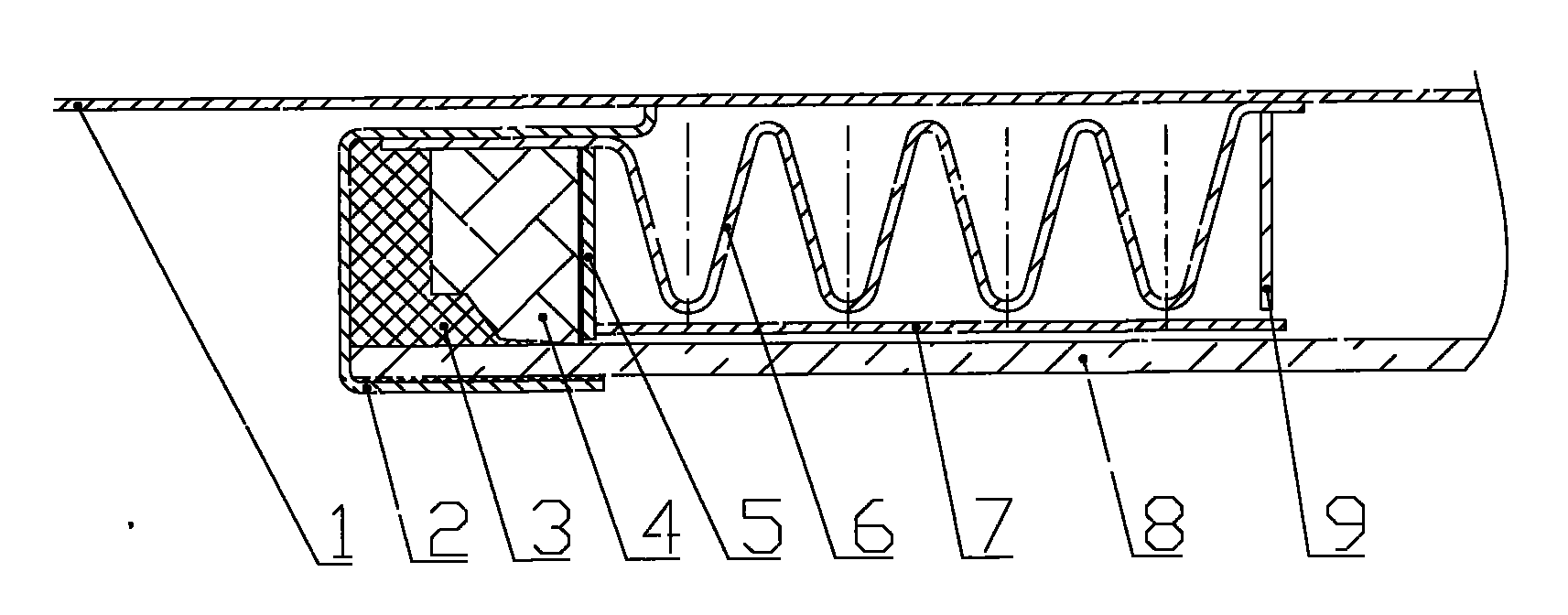

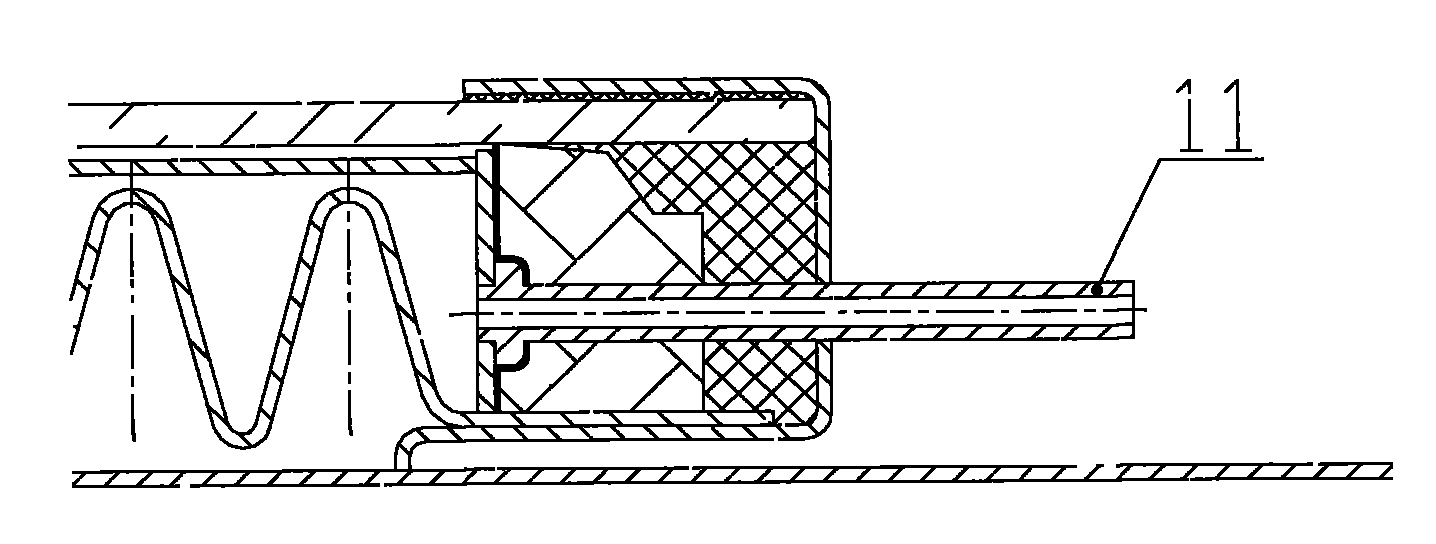

[0013] like figure 1 , figure 2 and image 3 As shown, the high-temperature heat-gathering vacuum tube includes a heat-absorbing metal tube (1), a corrugated tube (6), a corrugated tube sheath (7), a high borosilicate glass tube (8), and a protective ring (9), and is characterized in that: It also includes an open-hole ceramic copper clad ring (10) containing a vacuum suction pipe (11), a protective cover (2), glass adhesives (3) and (3a), a ceramic copper clad ring (4), a sealing ring (5 ) and (5a). The heat-absorbing metal pipe (1) is sealed and welded to the bellows (6), the bellows (6) is sealed to welded to the sealing ring (5), and the sealing ring (5) is sealed to welded to the copper clad surface of the ceramic copper clad ring (4), The glass adhesive (3) or (3a) forms a whole with sealing performance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com