Plasma induced damage (PID) detection structure and manufacture method thereof

A technology of damage detection and manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electric solid-state devices, etc., and can solve the problem of inability to accurately detect the size of the electric charge of the antenna structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

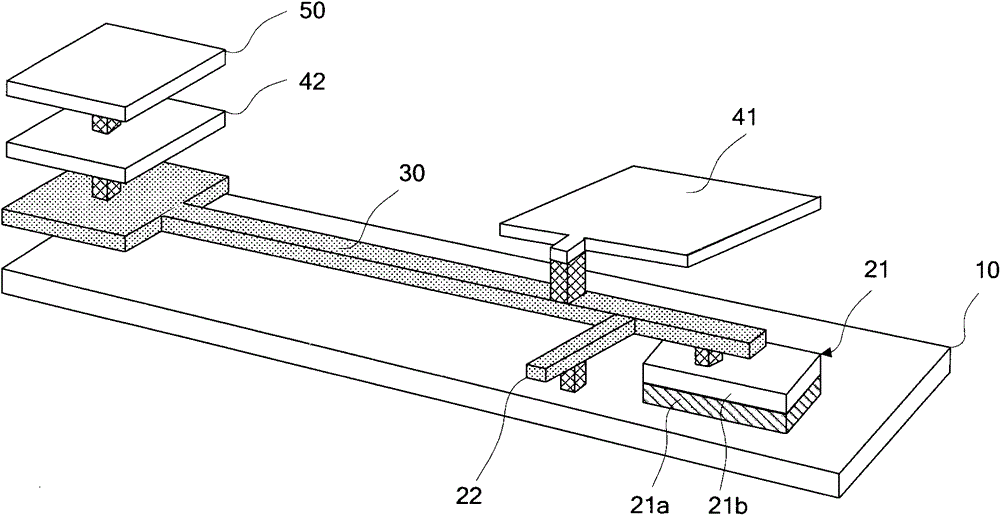

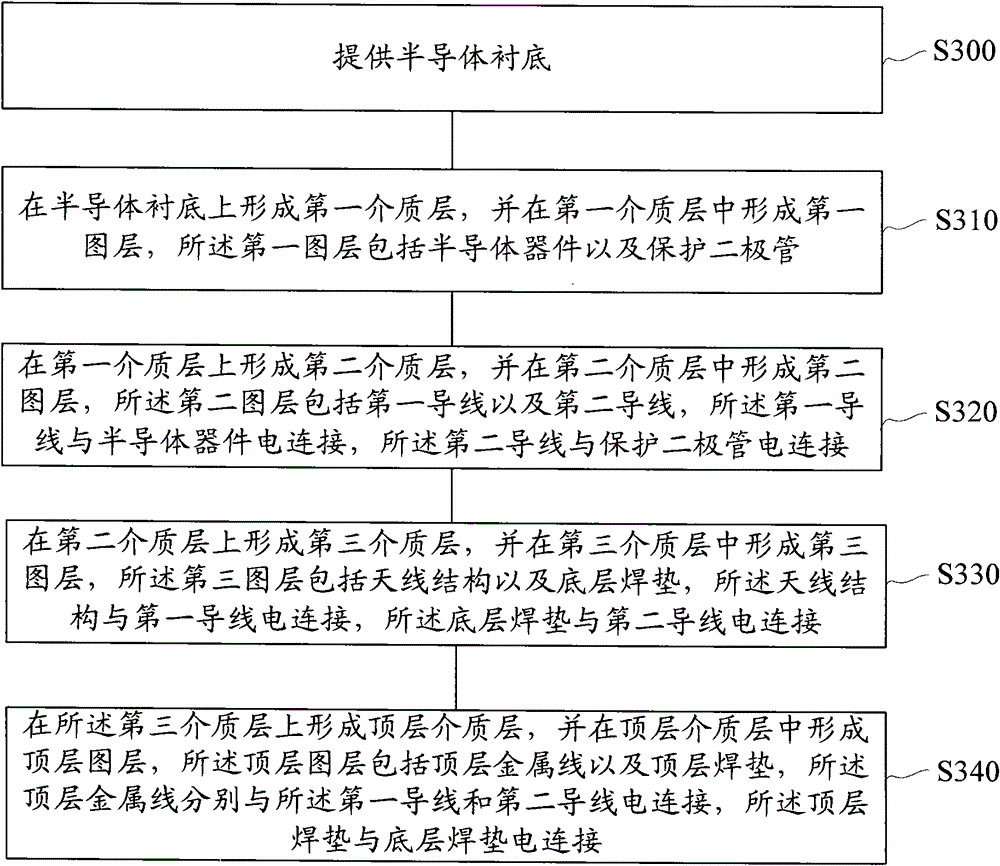

[0039] Please refer to figure 2 , which is a schematic diagram of the plasma damage detection structure provided by the first embodiment of the present invention, such as figure 2 As shown, the plasma damage detection structure provided by the first embodiment of the present invention includes: a semiconductor substrate 100, a first layer, a second layer, a third layer and a top layer.

[0040] The first layer is disposed in the first dielectric layer, and the first layer includes the semiconductor device 210 and the protection diode 220 formed on the semiconductor substrate 100;

[0041] The second layer is disposed in the second dielectric layer, the second layer includes a first wire 310 and a second wire 320, the first wire 310 is electrically connected to the semiconductor device 210, and the second wire 320 electrically connected to the protection diode 220;

[0042] The third layer is disposed in the third dielectric layer, and the third layer includes an antenna st...

no. 2 example

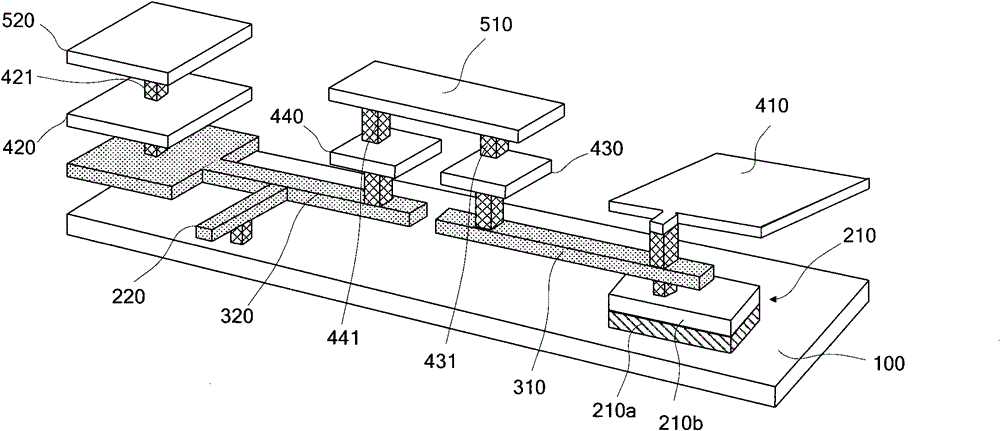

[0064] Please refer to Figure 5 , which is a schematic diagram of the plasma damage detection structure provided by the second embodiment of the present invention. Different from the first embodiment of the present invention, the plasma damage detection structure provided by the second embodiment of the present invention further includes covering the third An intermediate dielectric layer of the dielectric layer and a plurality of intermediate layers disposed in the intermediate dielectric layer.

[0065]Specifically, each intermediate layer includes an intermediate layer pad 620, a first intermediate layer metal wire 630 and a second intermediate layer metal wire 640, and the intermediate layer pad 620 is connected to the bottom layer pad 420 and the top layer pad respectively. 520 is electrically connected, the first middle layer metal wire 630 is respectively electrically connected with the first bottom layer metal wire 430 and the top layer metal wire 510, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com