Method and equipment for controlling constant polishing force of buffing machine

A control method and polishing force technology, applied in the field of polishing, can solve problems such as poor polishing effect, and achieve the effects of convenient standardized production, uniform polishing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

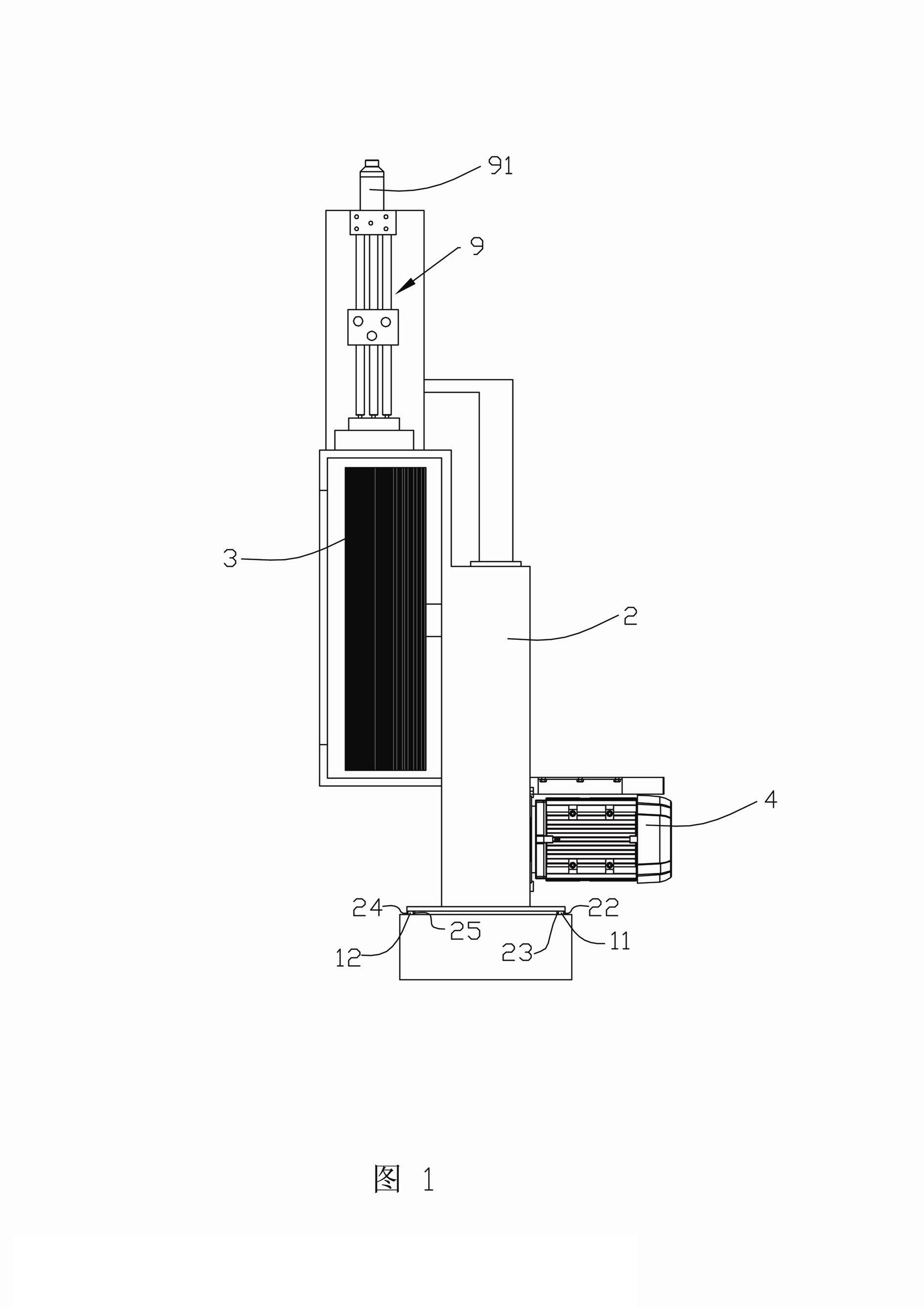

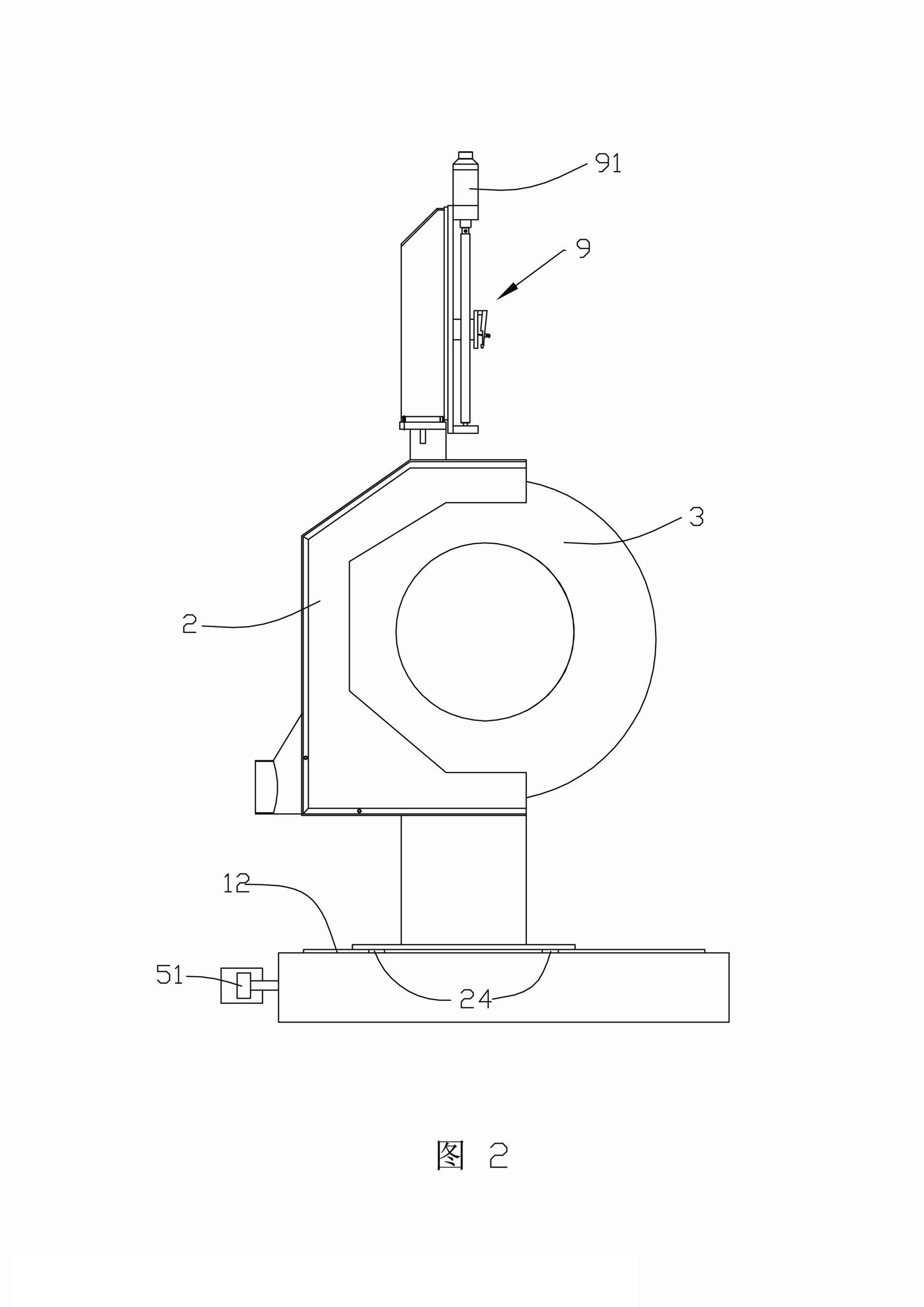

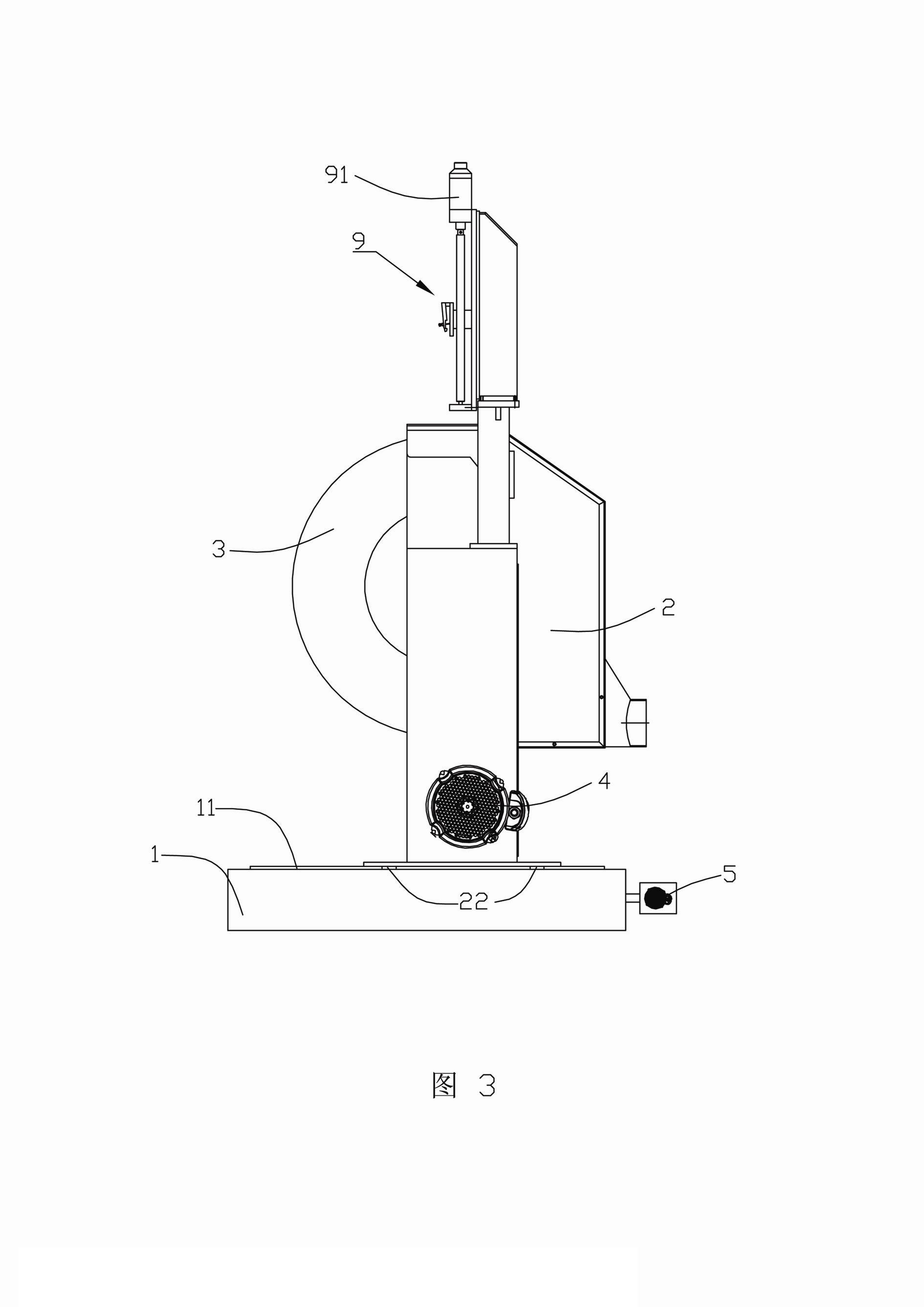

[0031] A method for controlling the constant polishing force of a cloth polishing machine, comprising the following steps:

[0032] a. The PLC control system sets the control parameters, starts the driving motor, and makes the cloth throwing wheel rotate;

[0033] b. The robot clamps the polished product and presses it on the circumference of the cloth polishing wheel for polishing, and keeps it;

[0034] c. The PLC control system obtains the real-time working current of the driving motor of the cloth throwing wheel through the frequency converter, and obtains the real-time working radius of the cloth throwing wheel through the servo motor;

[0035] d. The PLC control system obtains the real-time polishing force of the cloth throwing wheel according to the real-time working current and real-time working radius obtained above. When the real-time polishing force is greater than the set polishing force, the PLC control system sends a signal to make the driver drive The servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com