Diffusion plate of multilayered diffusion particle layer

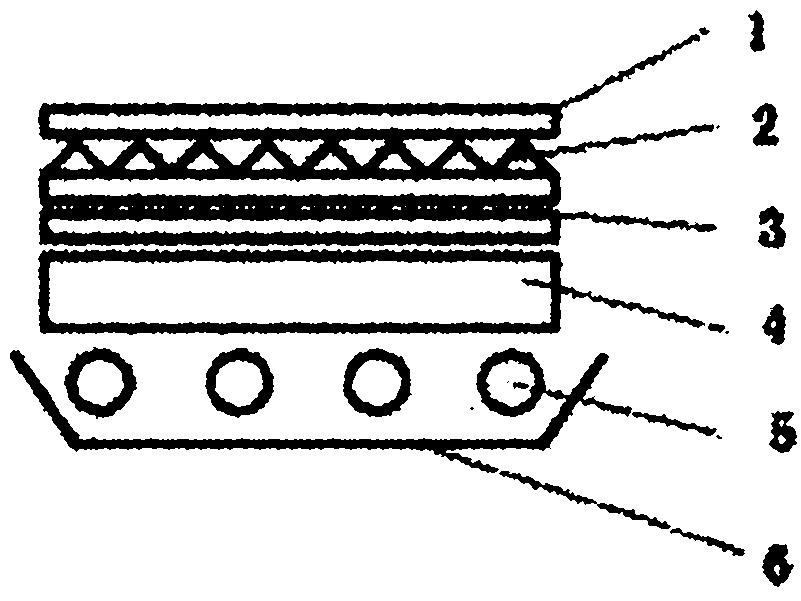

A technology of diffusion particles and diffusion plates, which is applied in the field of diffusion plates, can solve problems such as high cost and difficult processing, and achieve the effects of increasing brightness, uniformly diffusing light, and strong anti-ultraviolet absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

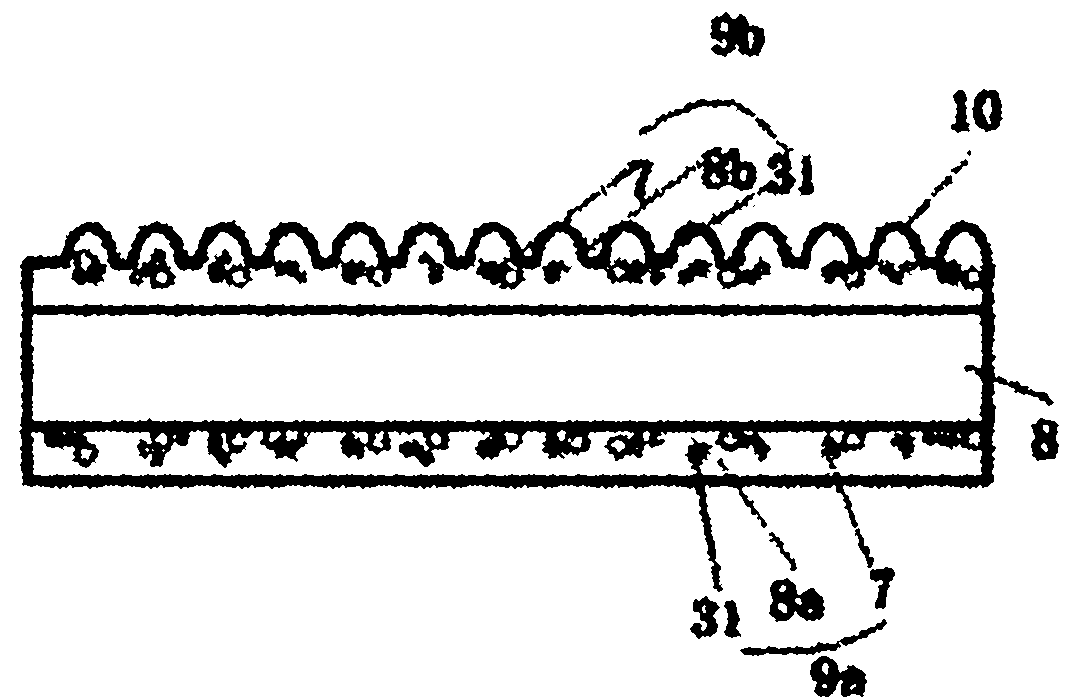

Embodiment 1

[0043] Such as figure 2 As shown, the present invention is a structural schematic diagram of Embodiment 1 of a diffusion plate with multiple diffusion particle layers. The light diffusing particles 31 are doped in the first diffusing particle layer 9a and the second diffusing particle layer 9b, and the transparent resin substrate layer 8 is sandwiched therein. The thicknesses of the transparent resin substrate intermediate layer 8 and the first diffusion particle layer 9 a and the second diffusion particle layer 9 b are all 1 mm. The doping amount of diffusion particles and ultraviolet absorber in each layer of diffusion particle layer accounted for 0.04% and 0.004% by weight of the current layer of diffusion particle layer respectively. There are a plurality of hemispherical structures 10 arranged in a rectangle on the upper surface of the diffusion plate, the radius of the spheres is 0.1 mm, and the distance between the centers of the spheres is 0.4 mm.

[0044] The middl...

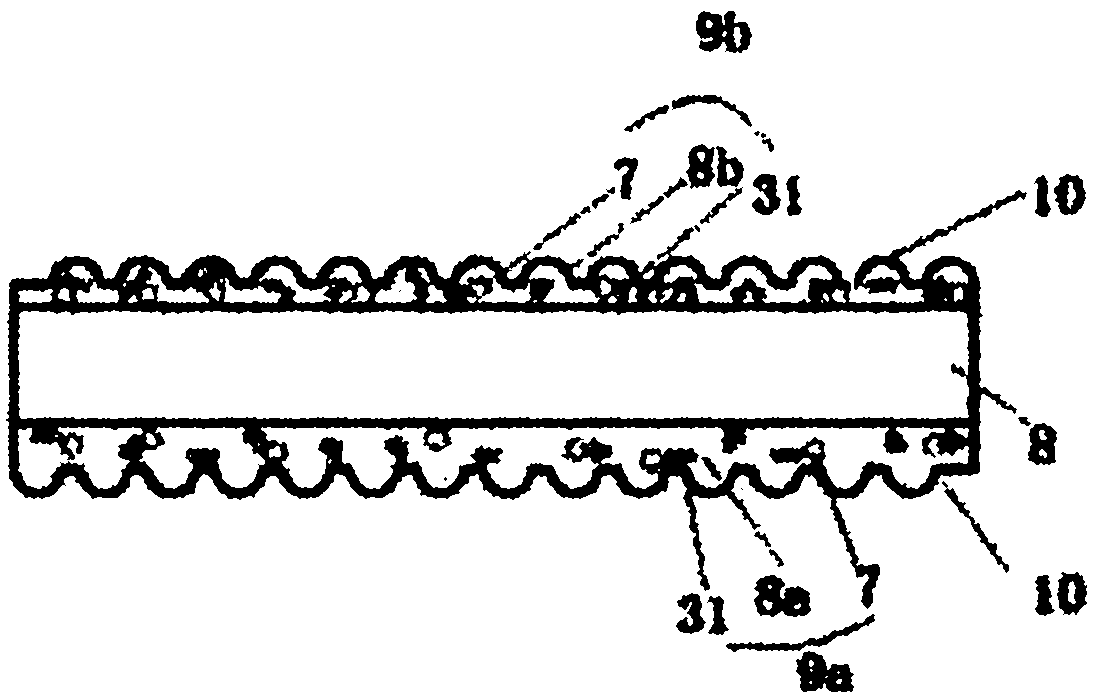

Embodiment 2

[0046]The main difference between embodiment 2 and embodiment 1 is that the lower surface of the diffusion plate in embodiment 2 has a plurality of hemispherical structures 10 arranged in a rectangle, the radius of the spheres is 0.1 mm, and the distance between the centers of the spheres is 0.4 mm.

Embodiment 3

[0048] Such as image 3 Shown is a schematic structural view of another preferred embodiment 3 of the present invention. The main difference between embodiment 3 and embodiment 1 is that there are a plurality of hemispherical structures 10 arranged in a rectangle on the upper and lower surfaces of the diffusion plate in embodiment 3, the radius of the spheres is 0.1 mm, and the distance between the centers of the spheres is 0.4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com