Optical fibre plug, optical fibre socket and optical fibre connector

A technology of optical fiber plug and optical fiber socket, which is applied in the coupling of optical waveguide and other directions, can solve the problems of optical signal loss, optical axis misalignment, and reduced signal transmission performance of optical fiber coupling connectors, so as to achieve accurate alignment and ensure signal transmission performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

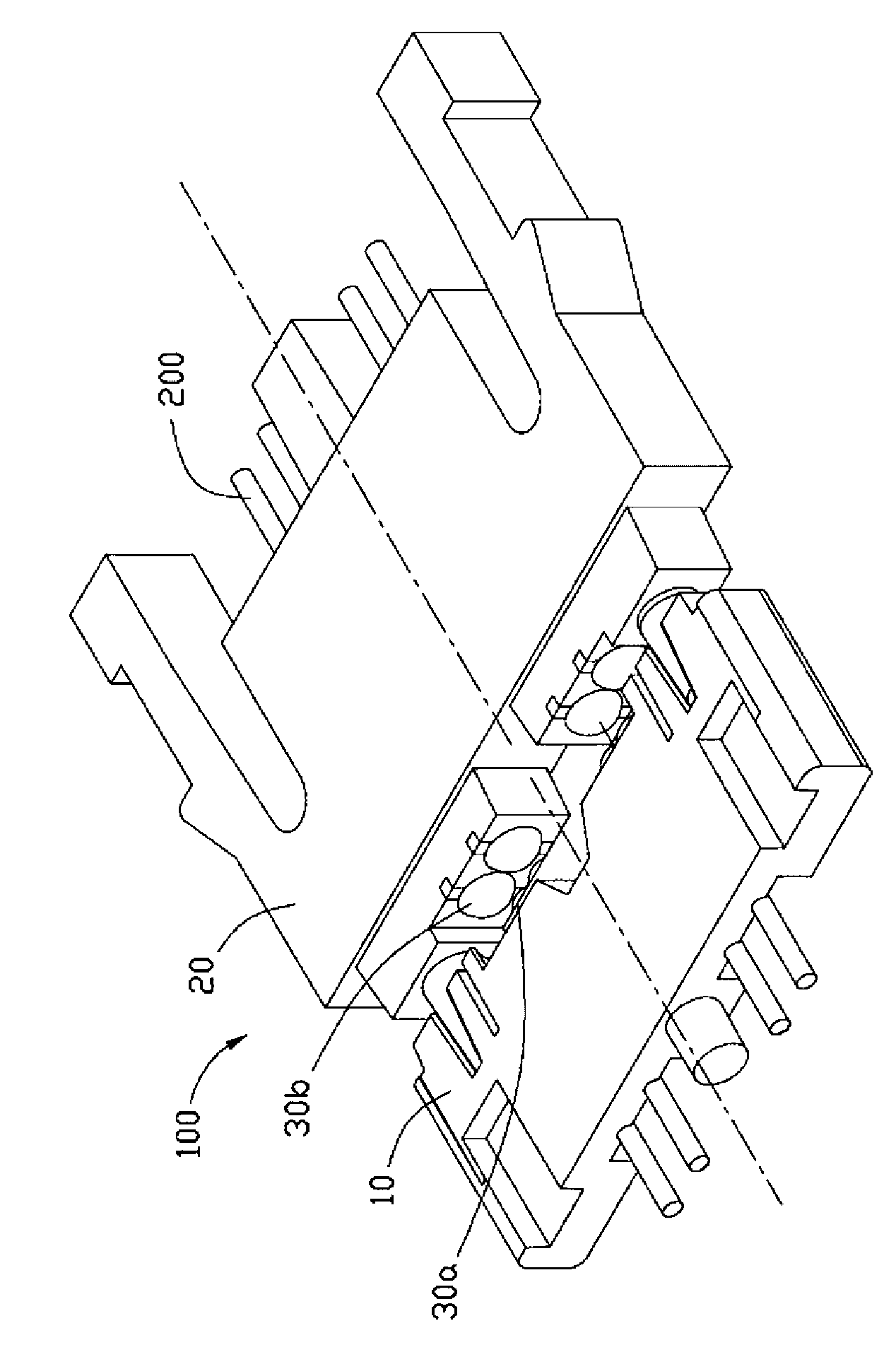

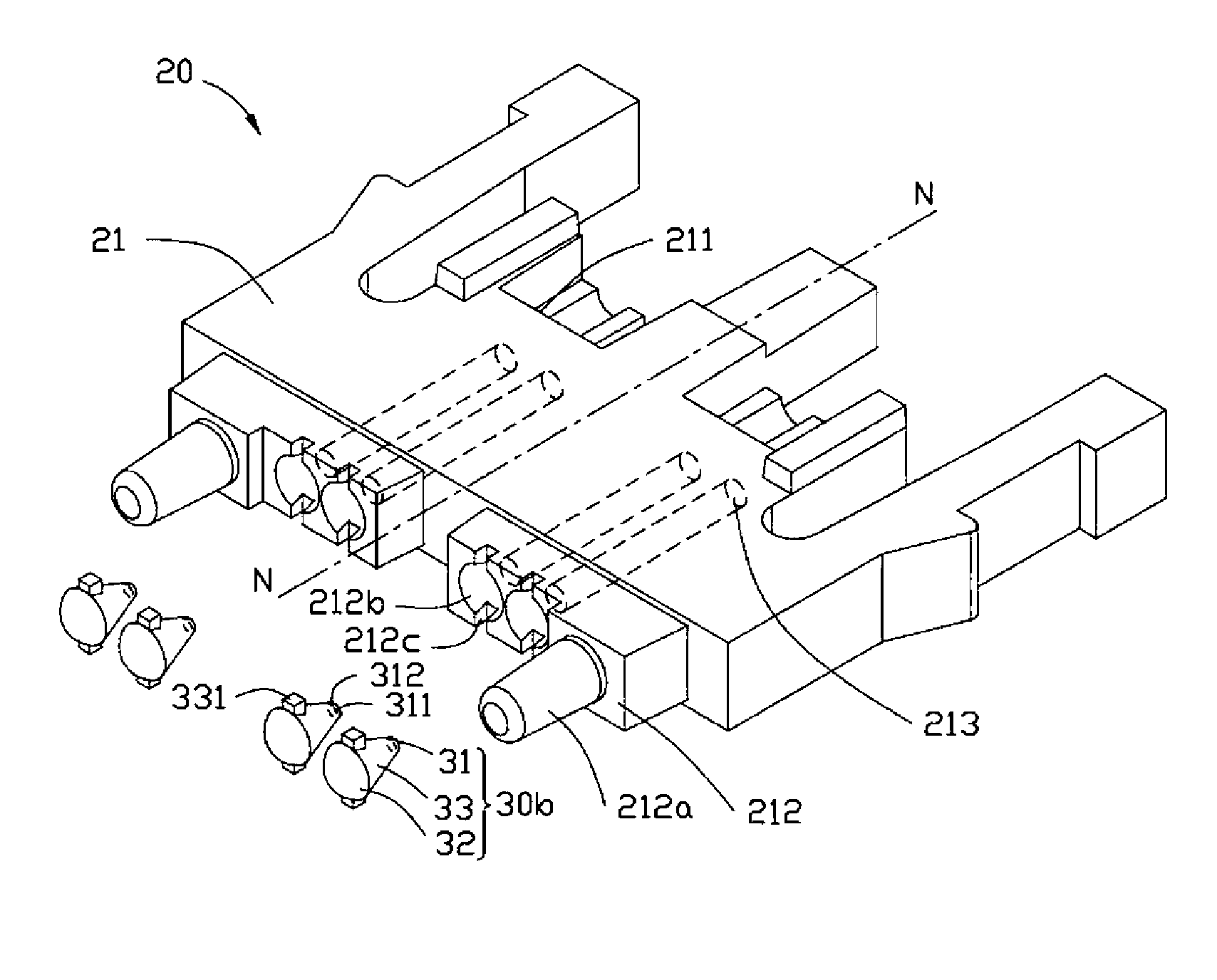

[0040] Such as Figure 1 to Figure 3 As shown, it is an optical fiber connector 100 provided by the embodiment of the present invention, which is used for coupling and connecting an optical fiber 200; The sockets 20 cooperate with each other.

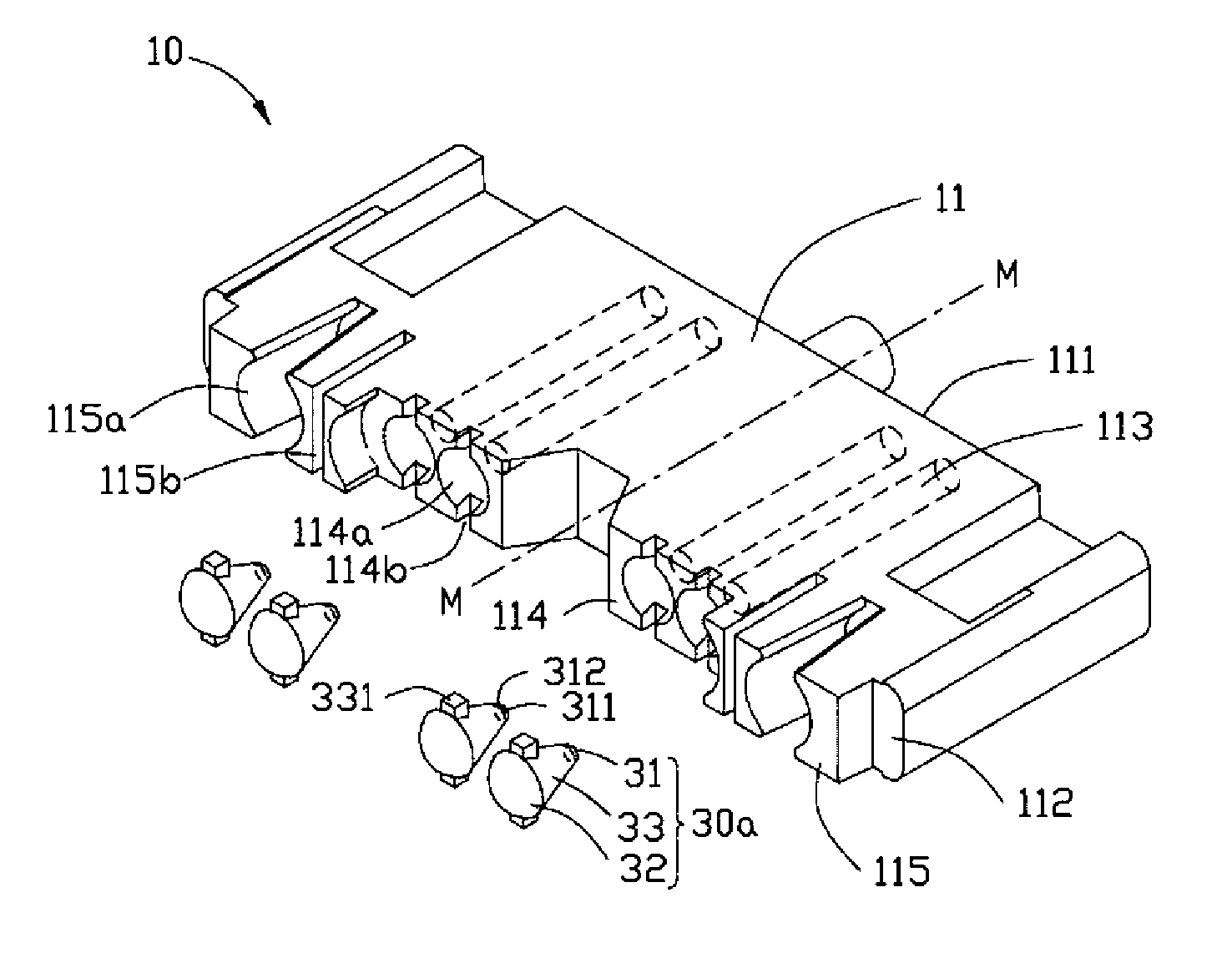

[0041] The fiber optic plug 10 includes a first body 11 and at least one first focusing lens 30a. The first body 11 includes a first end surface 111 , a second end surface 112 opposite to the first end surface 111 , and a symmetry axis M perpendicular to the first end surface 111 and the second end surface 112 . At least one first guide hole 113 extending toward the second end surface 112 along a direction parallel to the axis of symmetry M is defined on the first end surface 111 . In this embodiment, the number of the first guide holes 113 is four and two pairs are symmetrically distributed on both sides of the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com