Machining method for online measurement and compensation of high-precision blade

A processing method and high-precision technology, applied in instruments, computer control, simulators, etc., can solve problems such as measurement errors, and achieve the effect of improving processing qualification rate, processing efficiency and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

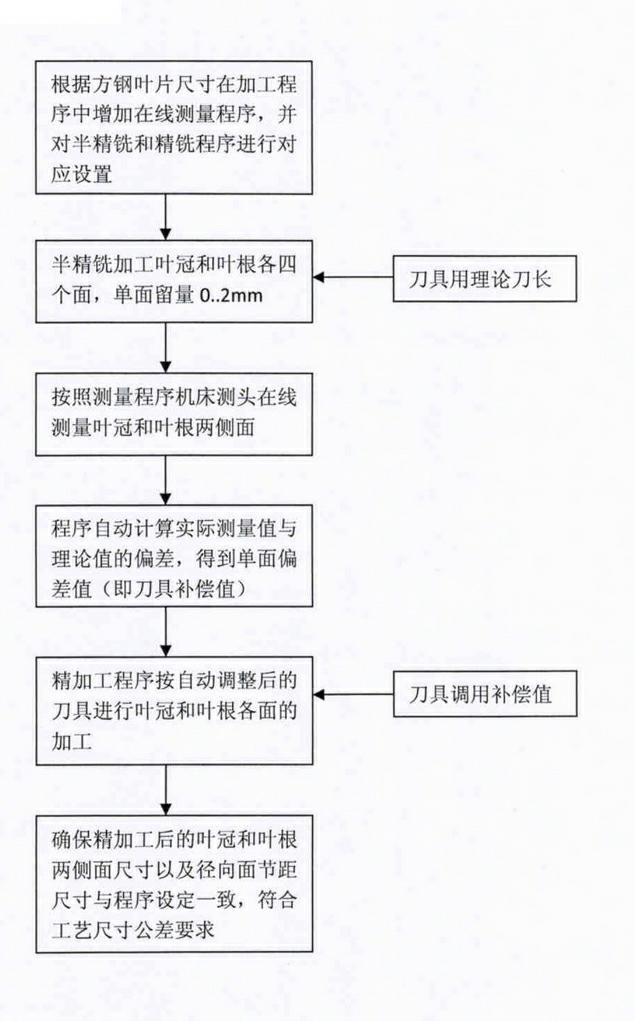

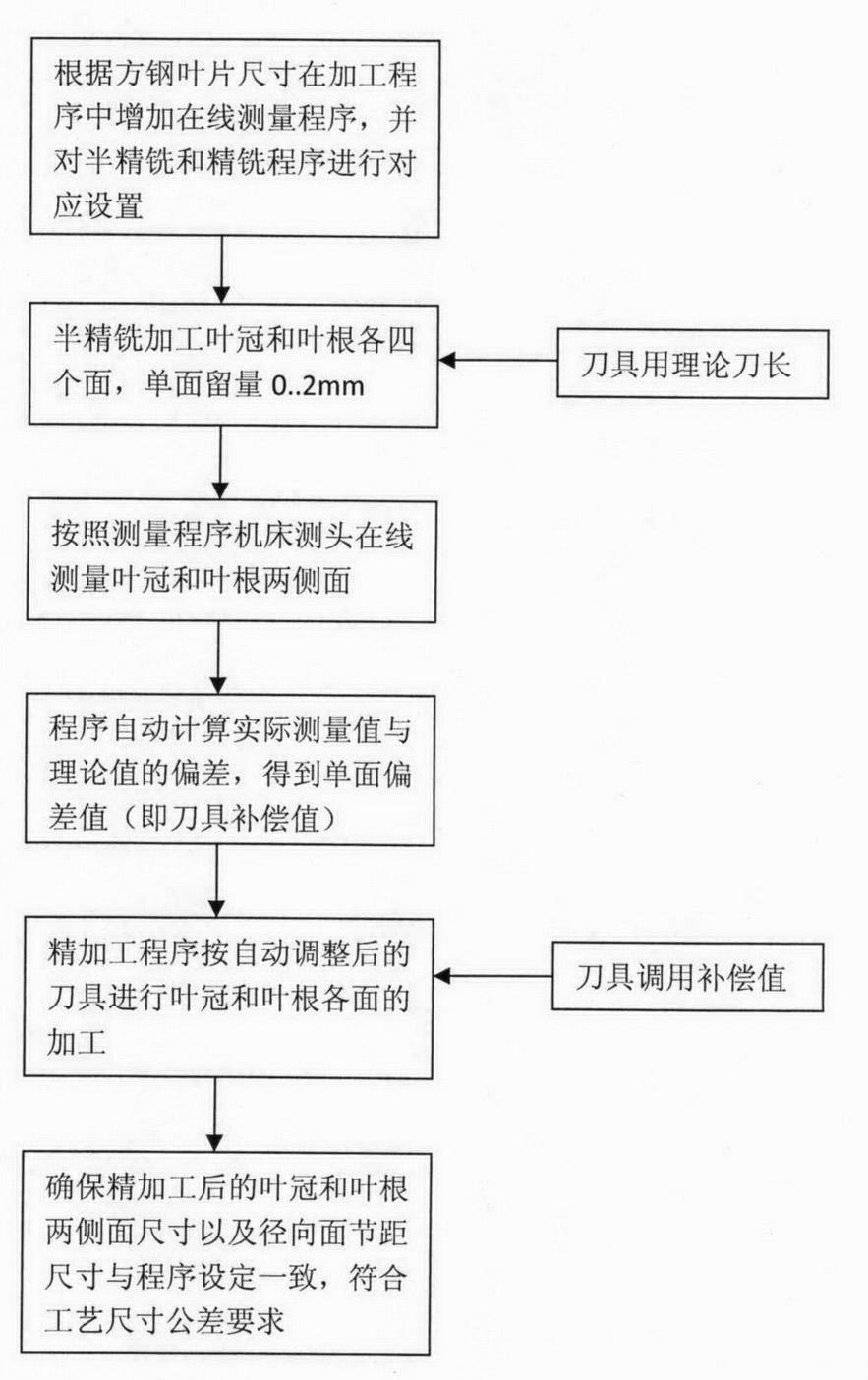

[0018] The size of both sides of the crown of a square steel blade is 35mm±0.03, and the size of the sides of the blade root is 40mm 0 -0.05 , the tolerance of the radial pitch of the blade shroud and the radial pitch of the blade root is +0.04mm~-0.02mm; during semi-finishing milling, it is processed according to the procedure of 0.2mm for one side, and the four sides of the blade shroud are used The φ20 face milling cutter is used for processing, and the four sides of the blade root are processed with a φ63 face milling cutter; after processing, online measurement is carried out according to the program, and the actual size value after semi-finishing milling is obtained at this time: the size of the two sides of the blade crown is 35.43mm (theoretical value should be 35.4mm), the size of both sides of the blade root is 40.45 (theoretical value should be 40.4mm), two compensation values can be obtained after comparing the online measurement program with the theoretical valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com