Inclined bidirectional rotary dish washing method and dish washing machine thereof

A two-way rotating and tilting technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of long washing time, high price and incomplete cleaning of dishwashers and other issues, to achieve strong price advantages and market competitiveness, low cost, and shorten the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

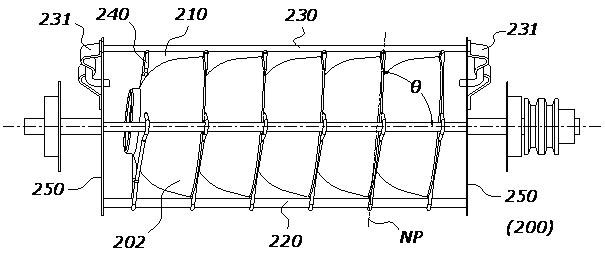

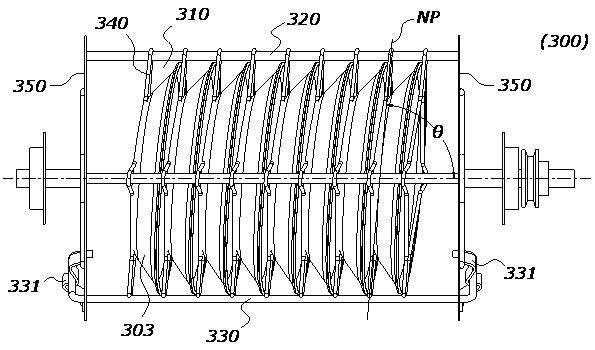

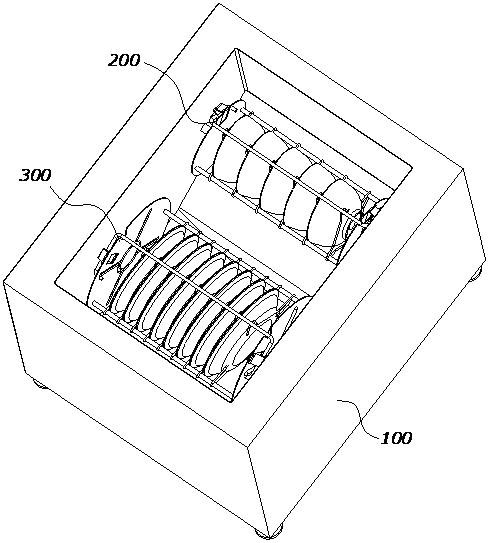

[0025] A method for washing dishes with an inclined two-way rotation of the present invention, one of its specific implementations, can be used in household electric dishwashers, such as figure 1 As shown, the dishwasher includes a cabinet 100 and a rotatable cage frame 200 (and / or 300) that is horizontally arranged inside the lower cabinet 100. The method for washing dishes with an inclined two-way rotation includes the following steps: figure 2 (or 3) shown, the utensil (bowl 202 or plate 303) to be cleaned is put into the compartment 210 (or 310) that is obliquely arranged on the cage frame 200 (or 300) relative to the cage frame 200 (or 300) rotation axis direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com