Aluminum alloy strip material rolling method

A technology of aluminum alloy strip and rolling speed, applied in the direction of metal rolling, metal rolling, rolling mill control device, etc., can solve the problem of increasing the production cost of the oil film on the surface of aluminum alloy strip, unfavorable promotion and application, and rolling affecting production efficiency and other problems, to achieve the effect of solving the sticky defect of coiling, avoiding the defect of coiling sticky and avoiding the lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

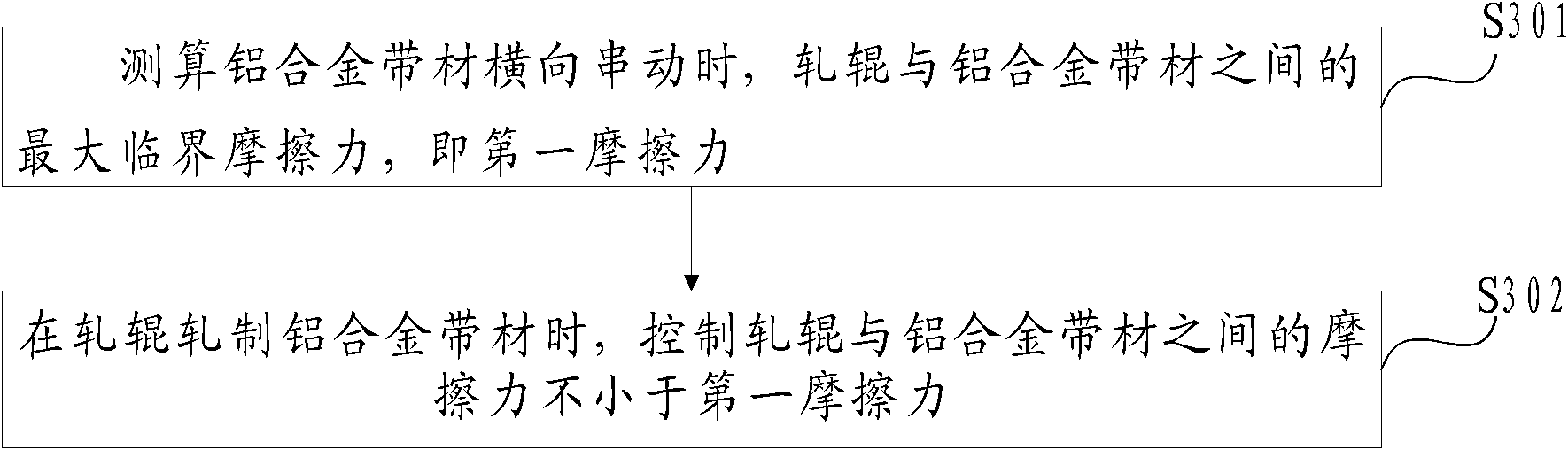

[0037] This embodiment provides a method for rolling an aluminum alloy strip, such as image 3 Shown is a schematic flow chart of the method, which specifically includes the following steps:

[0038] Step S301, measuring and calculating the maximum critical frictional force between the roll and the aluminum alloy strip when the aluminum alloy strip moves laterally, that is, the first friction force.

[0039] The first friction force described in this step can be determined through experimental calculation or theoretical calculation in the actual production process, that is, when the friction force between the roll and the aluminum alloy strip is less than the first friction force, the aluminum alloy strip may Transverse movement, when the frictional force between the roll and the aluminum alloy strip is greater than the first friction force, the aluminum alloy strip will not move laterally.

[0040] Step S302 , when the roll is rolling the aluminum alloy strip, the friction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com