Multistation automatic perforating machine for bicycle crank

A bicycle, multi-station technology, applied in the direction of manufacturing tools, boring/drilling, metal processing equipment, etc., can solve the problems of undiscovered patent documents of automatic bicycle crank punching machines, prone to work accidents, and low processing efficiency. , to achieve reasonable design, ensure product quality, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

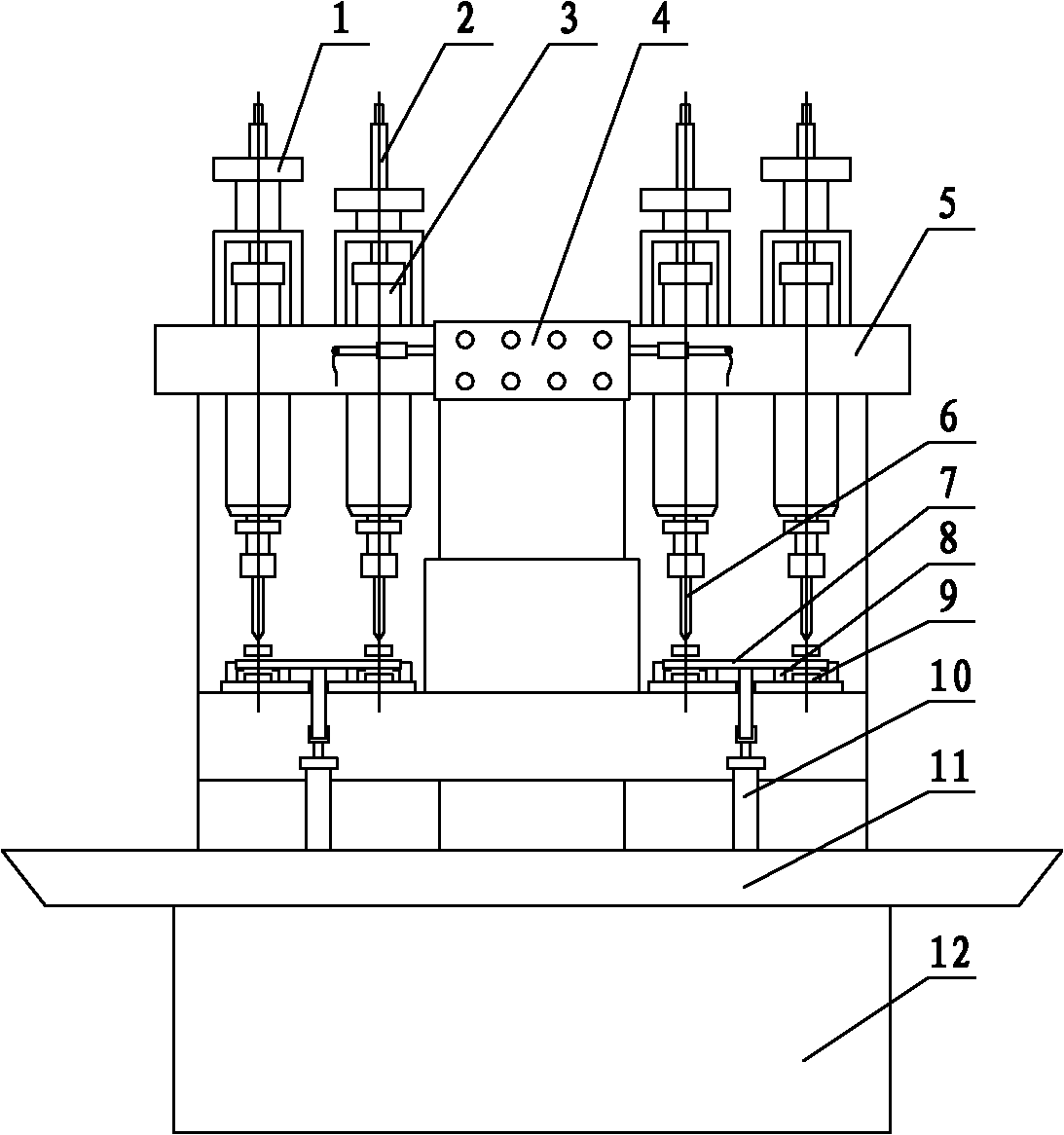

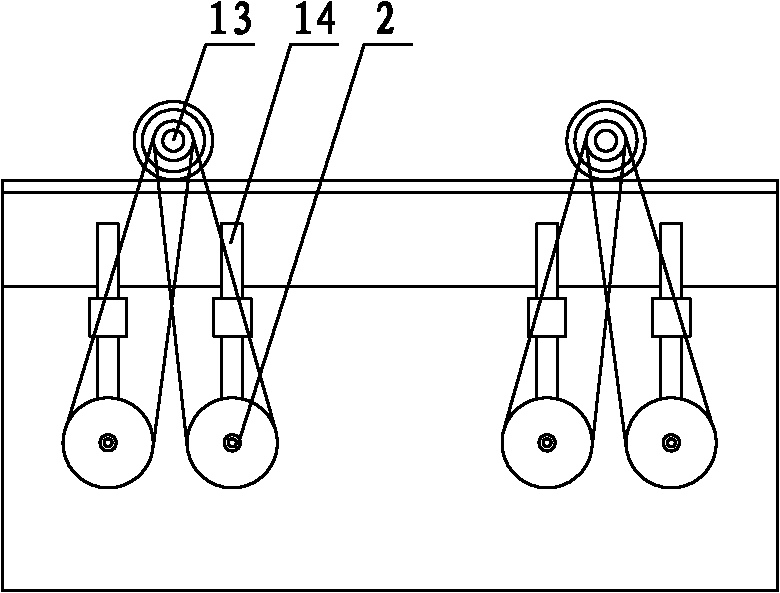

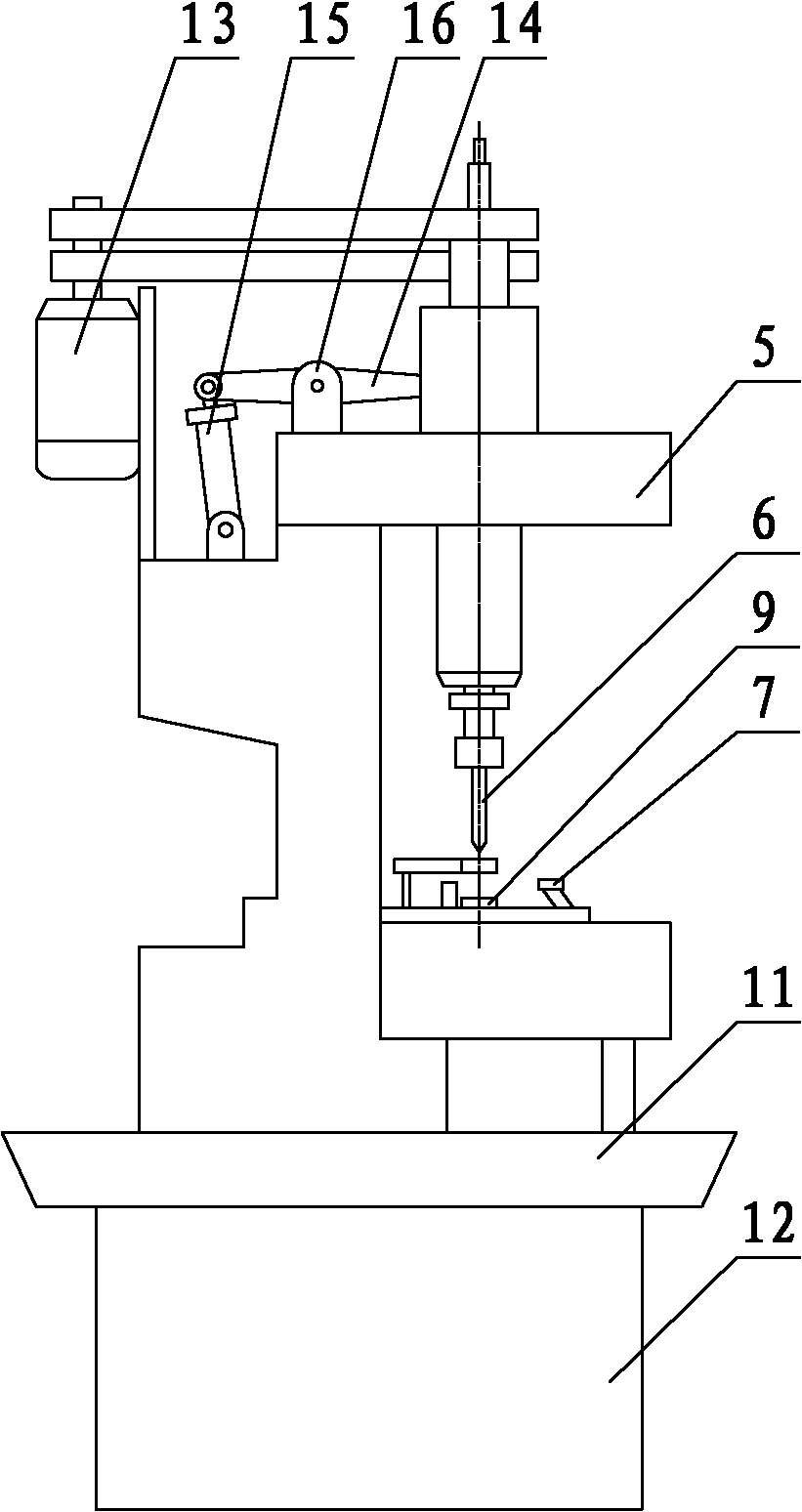

[0022] A multi-station bicycle crank automatic punching machine, comprising a base 12 and a body 5, the body is installed on the base, a waste liquid collection tank 11 is fixed between the base and the body, and a control device is installed on the body Run the control box4. A group of vertically arranged rotating shafts 2 are installed on the fuselage, and the rotating shaft is driven by a motor 13 installed on the back of the fuselage. In this embodiment, there are four rotating shafts, and two motors are installed on the back of the fuselage. The motor drives the two rotating shafts to rotate simultaneously through the belt 1 respectively.

[0023] The lower end of each rotating shaft is connected with a drill bit 6, and each drill bit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com