Rhinestone processing method and rhinestone grinding and polishing production line

A processing method and production line technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve problems such as high labor intensity, achieve the effects of halving labor intensity, improving the operating environment, and helping on-site management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

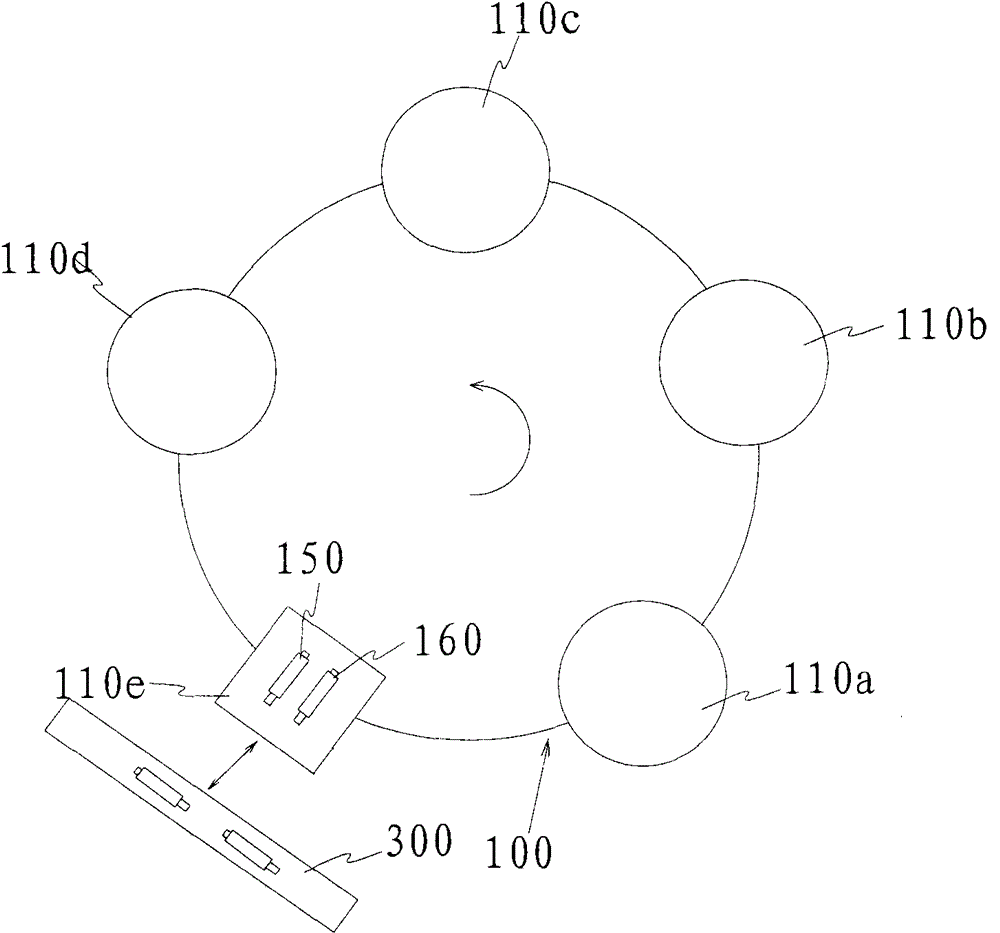

[0037] Combine below Figure 1 to Figure 3 The method for processing the rhinestones of the present invention is described. The purpose of the rhinestone processing is to process the spherical glass beads into rhinestones with front surfaces and rear surfaces.

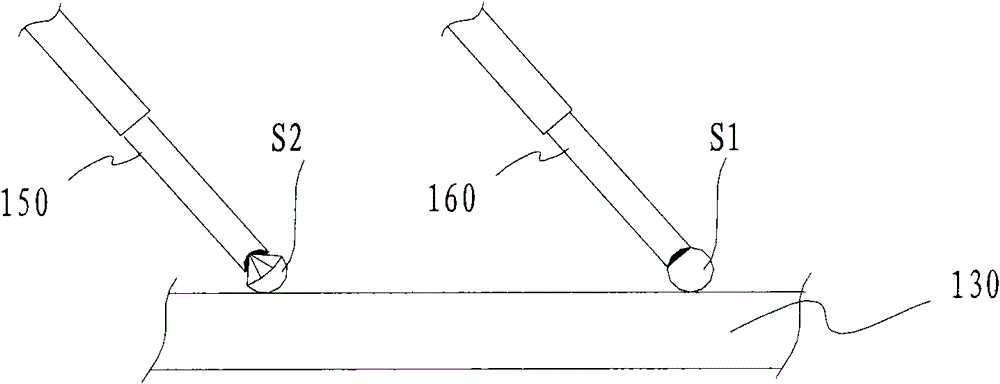

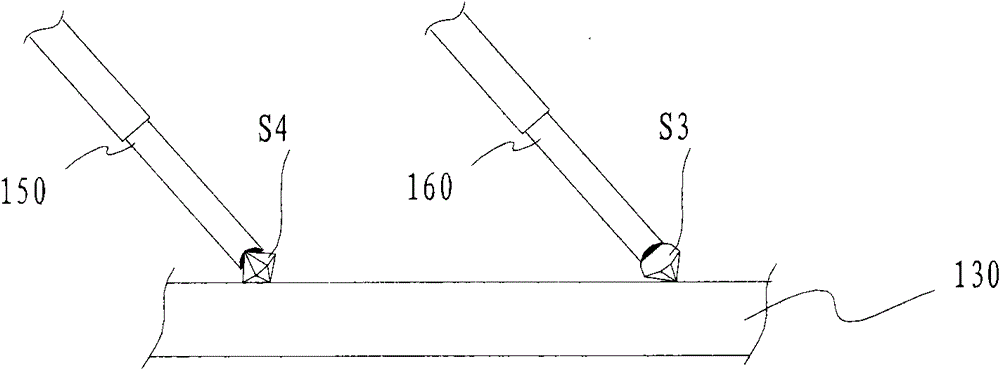

[0038] Step 1: Put two rows of glass beads S1 and S2 (such as figure 1 (Shown) grind sequentially on multiple grinding discs at the same time to obtain a row of glass beads S3 with front surfaces and a drain drill S4 (with front surfaces and rear surfaces) polished and polished (such as figure 2 Shown);

[0039] Step 2: Pass the row of glass beads S3 processed on each surface of the front portion obtained in Step 1 through butt joints to obtain the row of glass beads S2 required in Step 1.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com