Organometallic polymer ceramic precursor, and preparation method and application thereof

A ceramic precursor and organometallic technology, applied in the field of organometallic polymer ceramic precursors and their preparation, can solve the problems of poor solubility of precursors, low yield of ultra-high temperature resistant ceramics, and low content of ultra-high temperature resistant components metal materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0030] Reference example 1 Preparation of divinyl zirconocene: Add 29.282 g of dichloro zirconocene into a three-necked flask, add 2000 ml of ether solvent, dissolve, and cool down to -40 o C. Add 0.2 mol of vinyl Grignard reagent to the solution, react at constant temperature for 48 hours, filter after the reaction is completed, remove the solvent under reduced pressure, rinse twice with cold n-pentane, and recrystallize with toluene-n-pentane to obtain white di Vinyl zirconocene, yield 70-90%.

reference example 2

[0031] Reference example 2 Preparation of dipropenyl zirconocene: Add 29.282 g of dichloro zirconocene into a three-necked flask, add 2000 ml of ether solvent, dissolve, and cool down to -40 o C. Add 0.2 mol of propenyl Grignard reagent to the solution, react at constant temperature for 48 hours, filter after the reaction is completed, remove the solvent under reduced pressure, rinse twice with cold n-pentane, and recrystallize with toluene-n-pentane to obtain a white di Propyl zirconocene, yield 60-80%.

[0032] 2. Examples of preparation of polymers containing zirconocene, hafnium and titanium ceramic precursors

Embodiment 1

[0034] Under nitrogen protection, add 0.55 g (0.002 mol) divinylzirconocene (A 2 monomer) and 5 ml toluene at a constant temperature of -20 o C; Add 0.02 g (0.0014 mol) borane (B) dropwise under electromagnetic stirring 3 monomer) pyridine solution (concentration: 2.0 mol / L), reacted for 48 hours, the solution became viscous; added 100 ml of n-pentane, precipitated, filtered, 80 o C is dried, obtains Zr-B-C ceramic precursor polymer pale yellow polymer powder (referring to figure 1 ). Yield 85%.

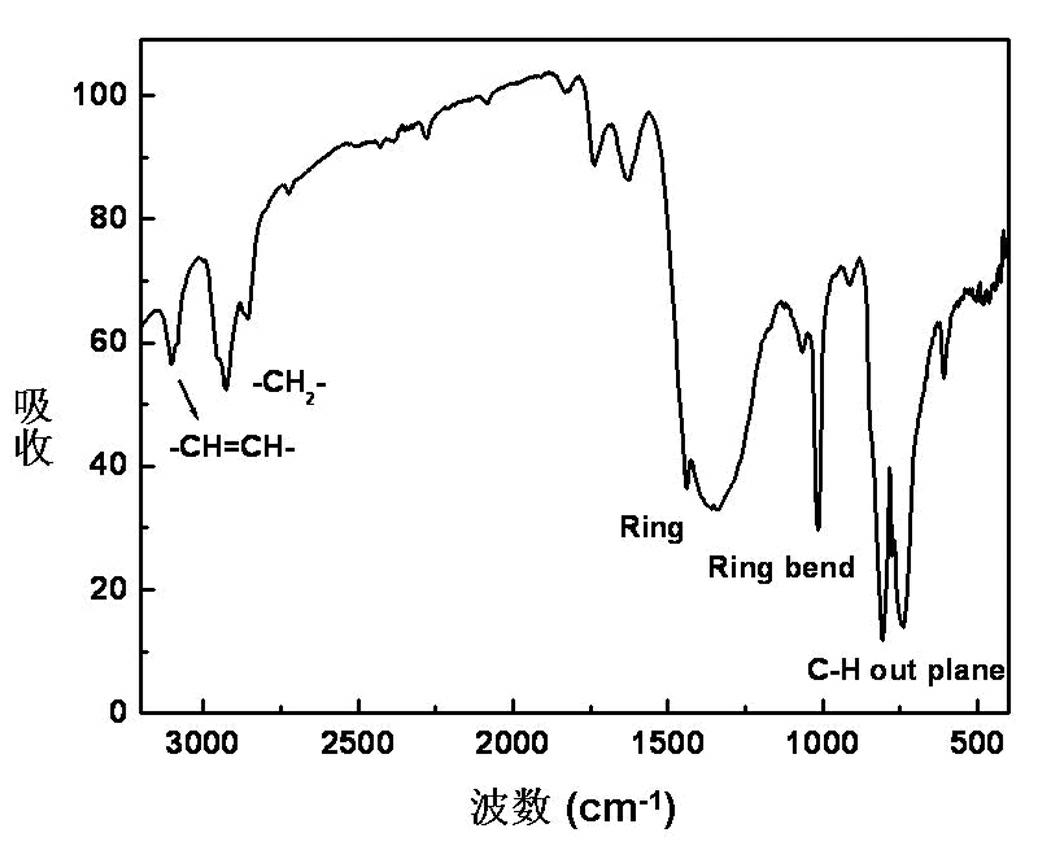

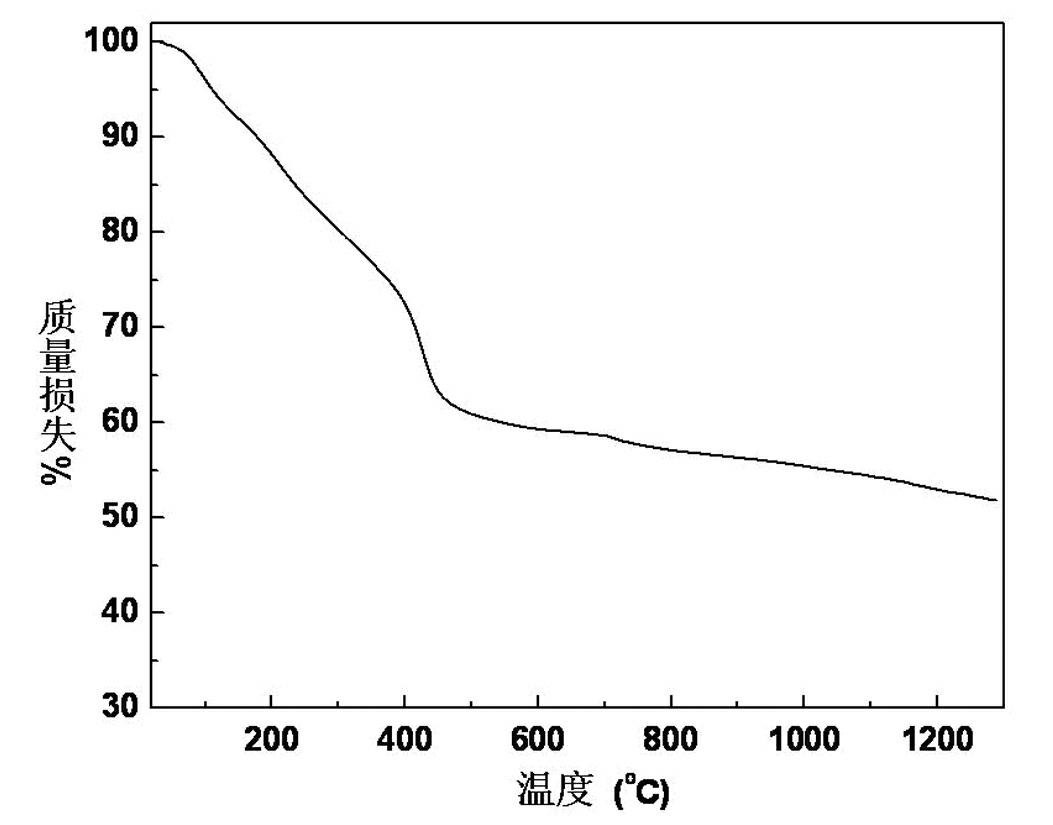

[0035] The obtained Zr-B-C ceramic precursor polymer is soluble in DMF, NMP, DMAc and DMSO. Through IR, 1 Structural characterization and testing of the precursor polymer by H NMR and TGA, in the IR spectrum, 3095 cm -1 and 2900 cm -1 The positions are the carbon-hydrogen vibration absorption peaks on the precursor polymer ring and the carbon-hydrogen vibration absorption peaks on the methylene on the main chain, respectively, at 1400 cm -1 、1100 cm -1 and 800 cm -1 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com