Heat-resistant hose lining reinforced by plant fiber

A technology of plant fiber and inner layer glue, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., to achieve good heat resistance, cooling liquid resistance, and improved elongation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

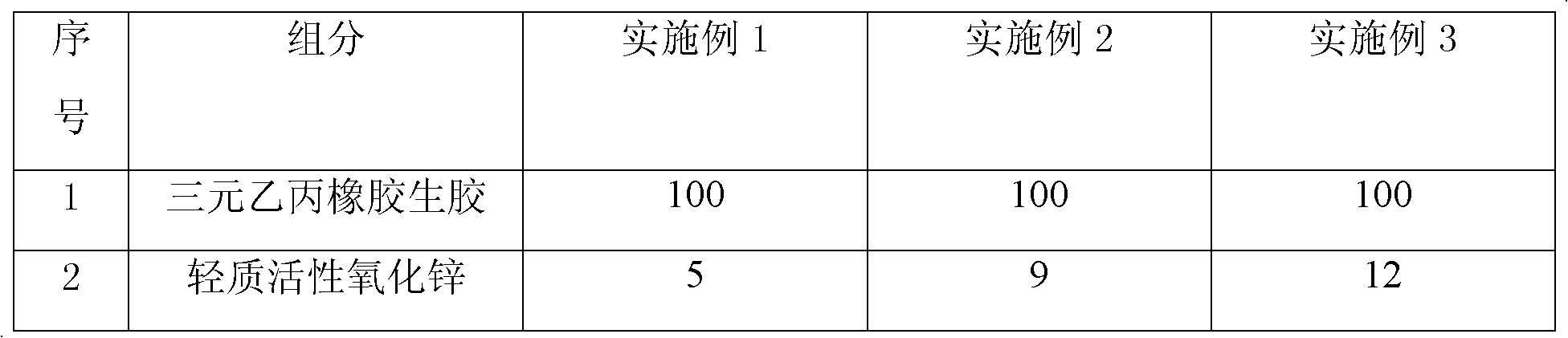

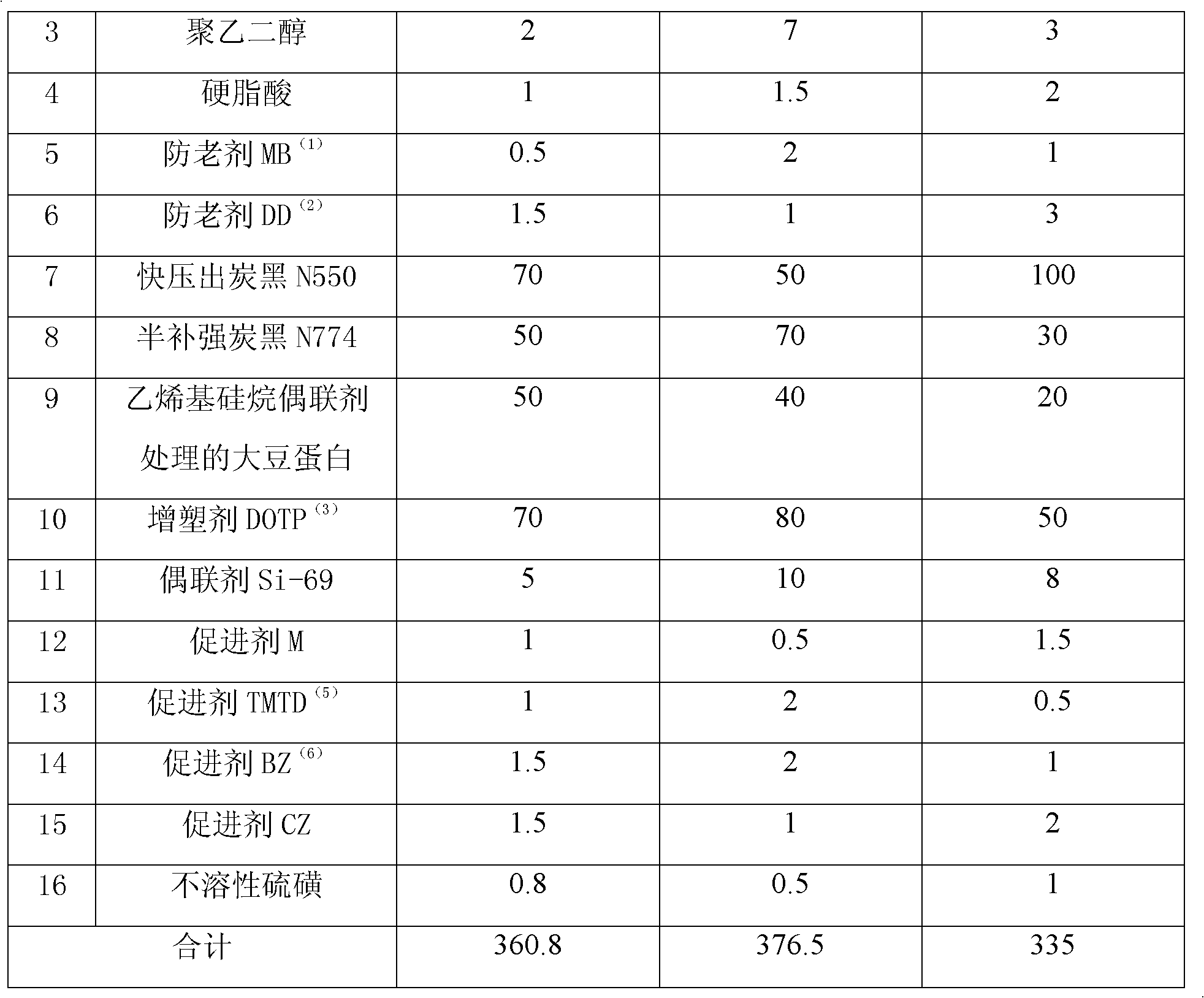

[0024] The embodiment of the formula for the inner layer glue of the heat-resistant hose reinforced with plant fibers in the present invention:

[0025] In parts by mass

[0026]

[0027]

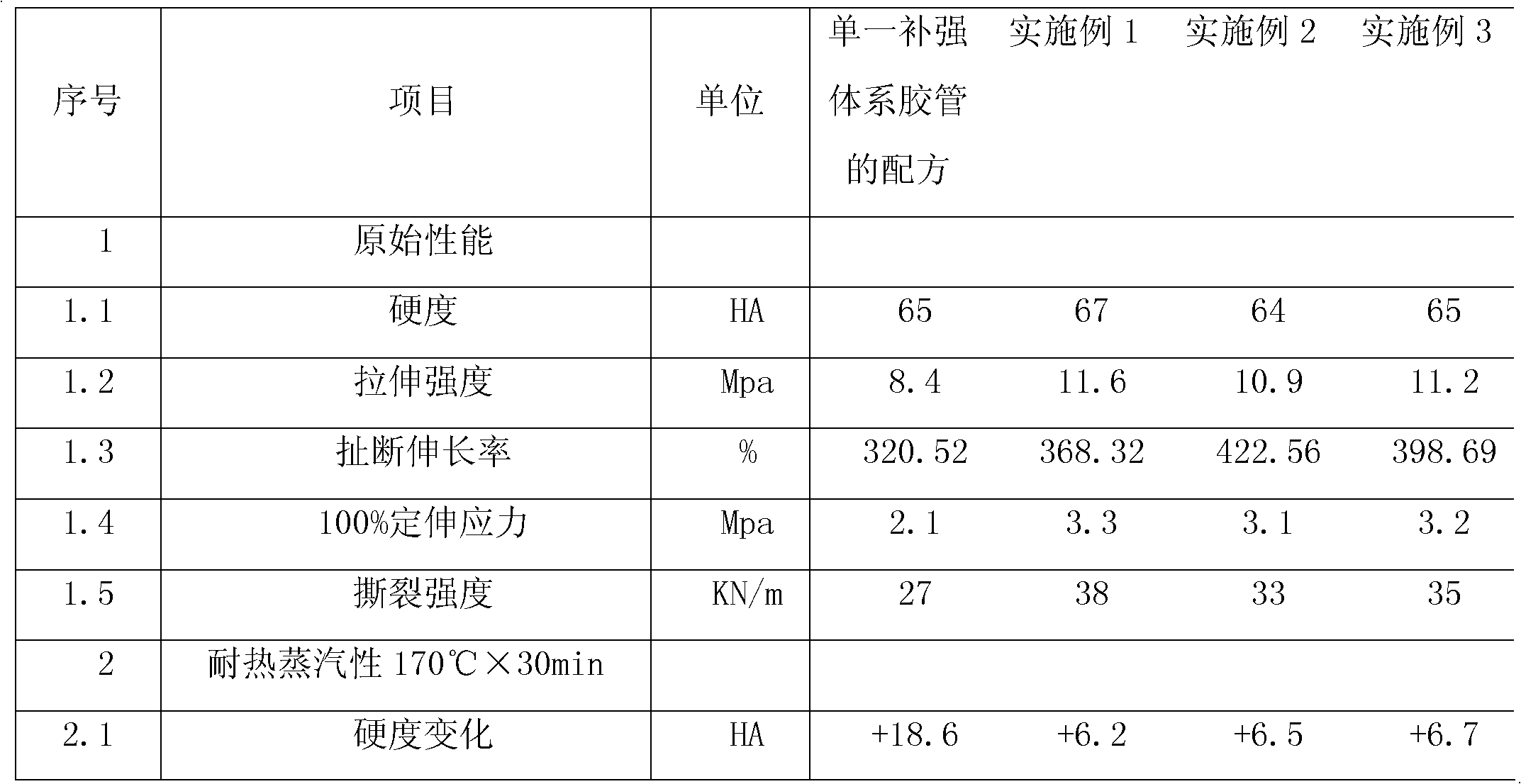

[0028] According to the raw materials in the formula listed in the implementation, the film is made into a film for testing. The performance comparison of the heat-resistant rubber tube reinforced with plant fiber and the rubber tube reinforced with single carbon black is as follows:

[0029]

[0030]

[0031] From the data in the above table, it can be concluded that the inner rubber of the heat-resistant hose reinforced with plant fibers has better heat resistance than the inner rubber of a single reinforcing system hose. Resistance, heat resistance, water vapor resistance, coolant resistance, ozone resistance, at the same time compression performance and elasticity are also very good, can also expand the capacity of the compound to reduce costs, and can better meet the conditions of long-term h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap