Automatic frequency conversion pulping system in household paper manufacturing process

A technology for manufacturing process and tissue paper, applied in the field of automatic frequency conversion pulping system, can solve the problems of high labor intensity of operators, low automation procedures, difficult control of process parameters, etc., to reduce maintenance difficulty, improve automation, reduce The effect of doing wasteful time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

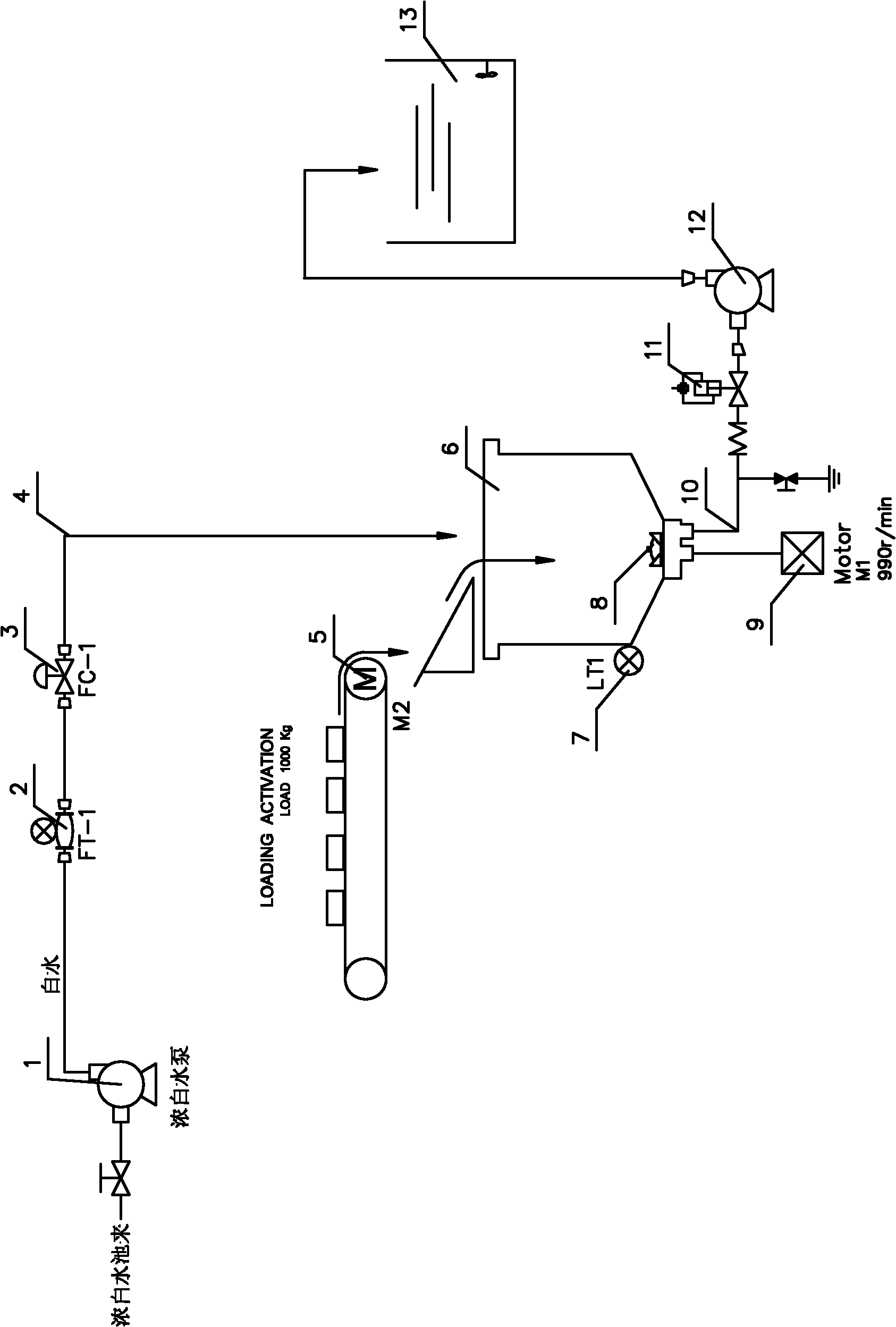

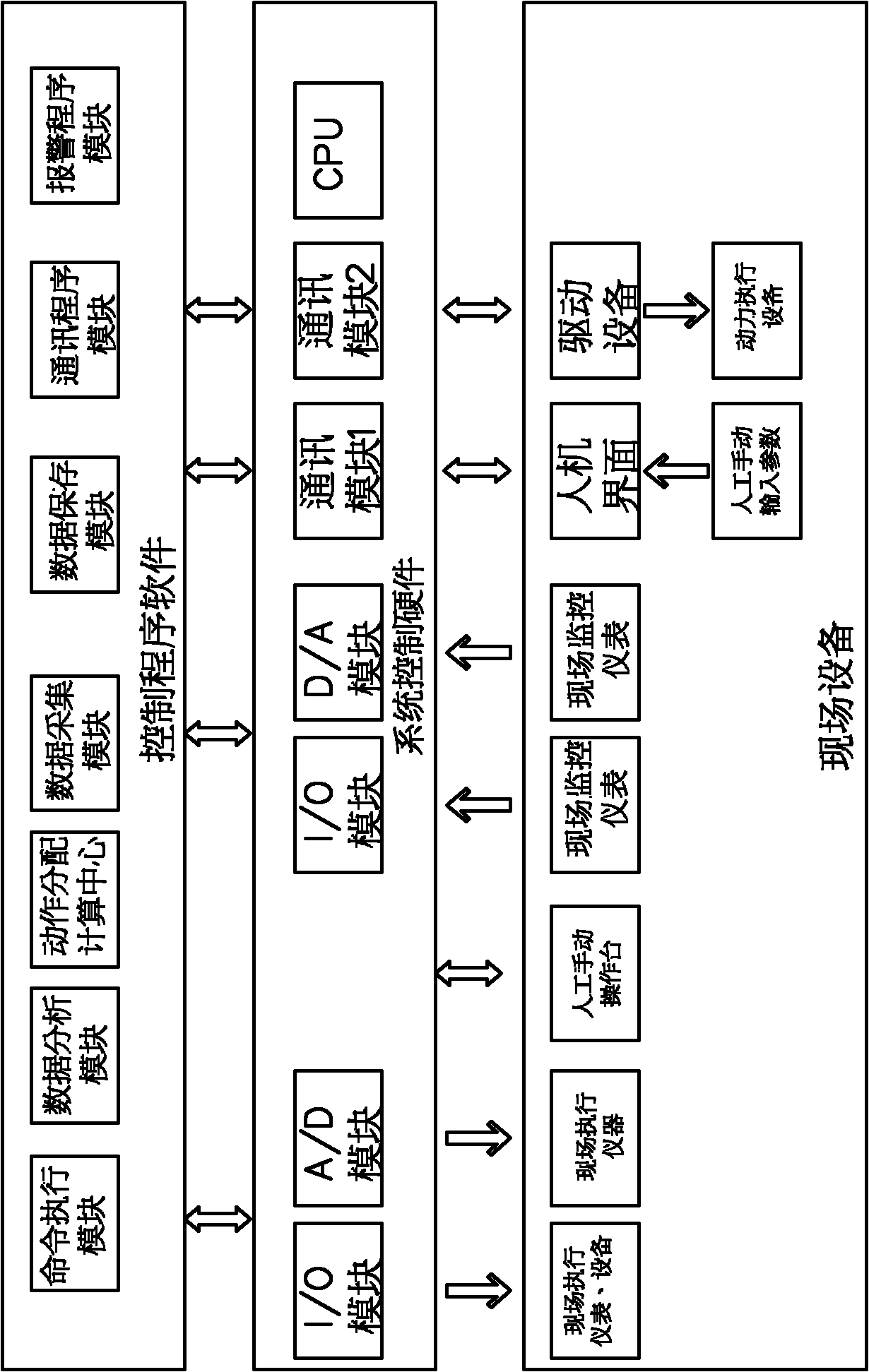

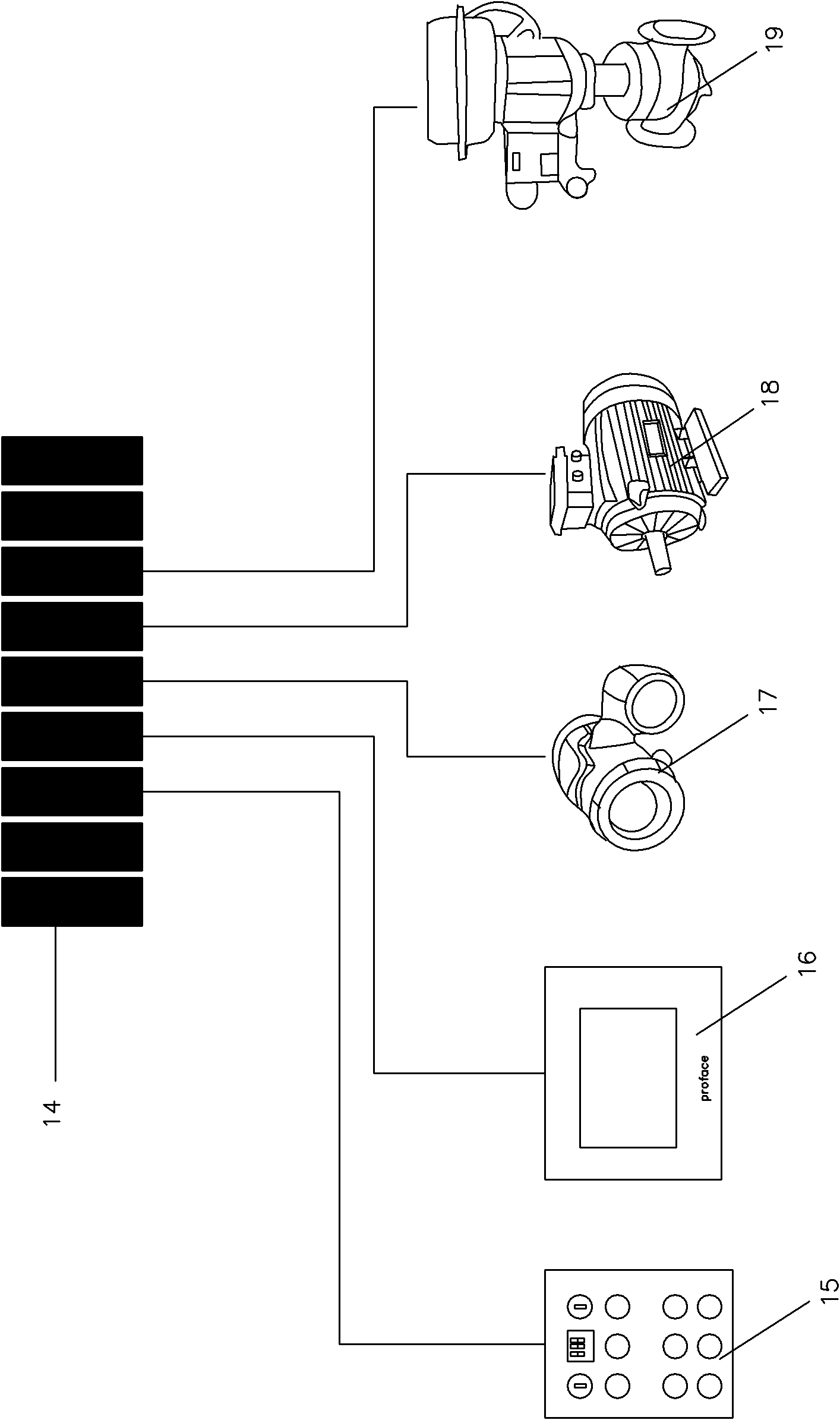

[0026] see Figure 1~3 As shown, the operation and control flow chart of the automatic frequency conversion pulping system of the present invention. The automatic frequency conversion pulping system in the household paper manufacturing process of the present invention includes a crushing and pulping process flow and an automatic control system. The automatic control system includes field devices, system control hardware, control program software and operating programs; among them, the field devices are connected with the system control hardware, and the operation of the system control hardware is controlled by the control program software; among them, the field devices include the instruments in the field process Instruments, consoles, execution equipment and drive equipment.

[0027] Such as figure 1 As shown, the crushing and depulping process flow of the present invention includes: a water adding process flow, a feeding process flow, a pulping process flow and a pulp pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com