Waterproof method for precast pile head

A technology of prefabricated pile heads and prefabricated piles, which is applied in the direction of protection devices, buildings, and infrastructure engineering, etc., can solve the problems that are not easy to do, and the flexible waterproof layer is difficult to achieve reliable waterproofing, so as to achieve the effect of improving the reliability of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

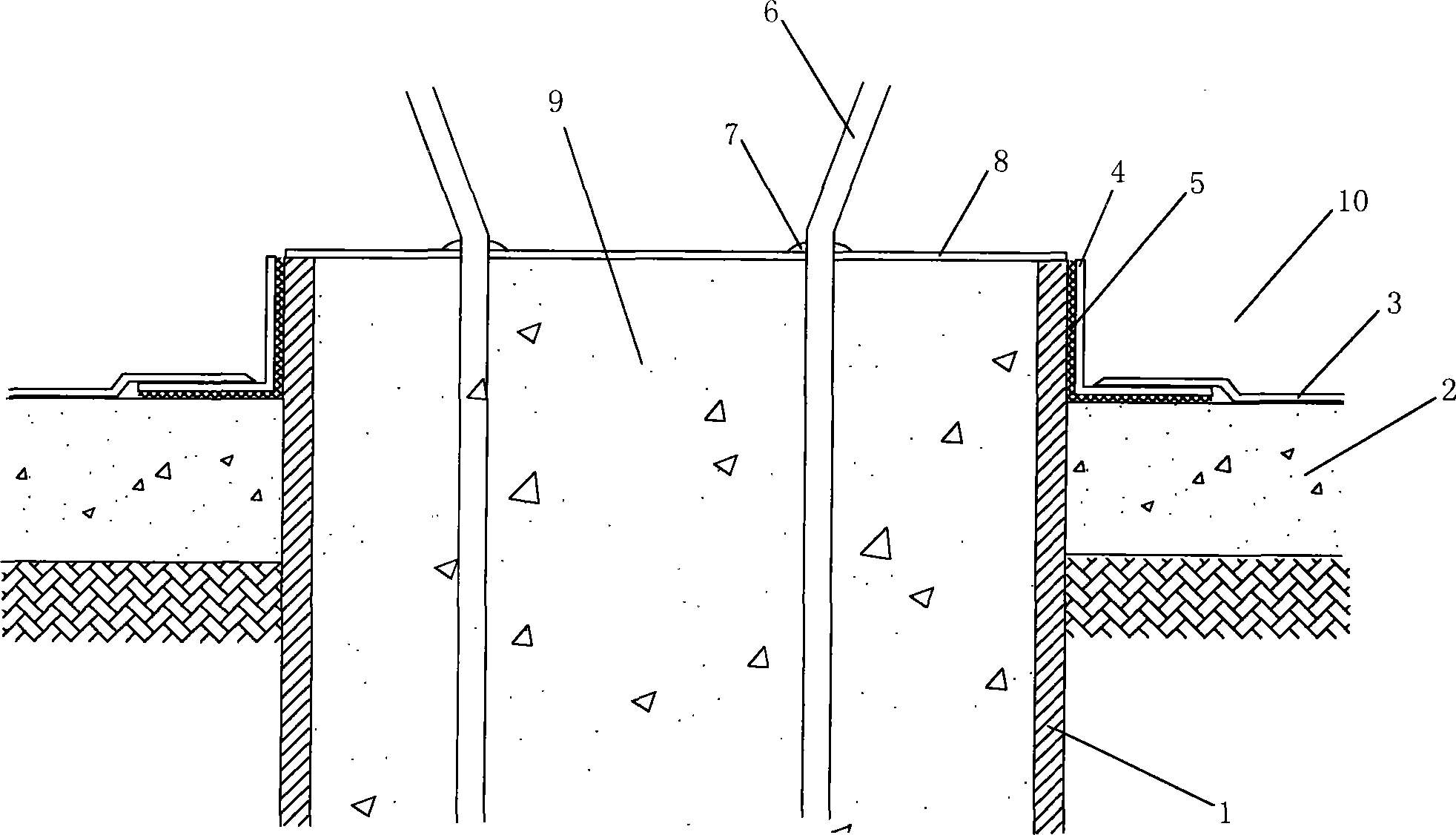

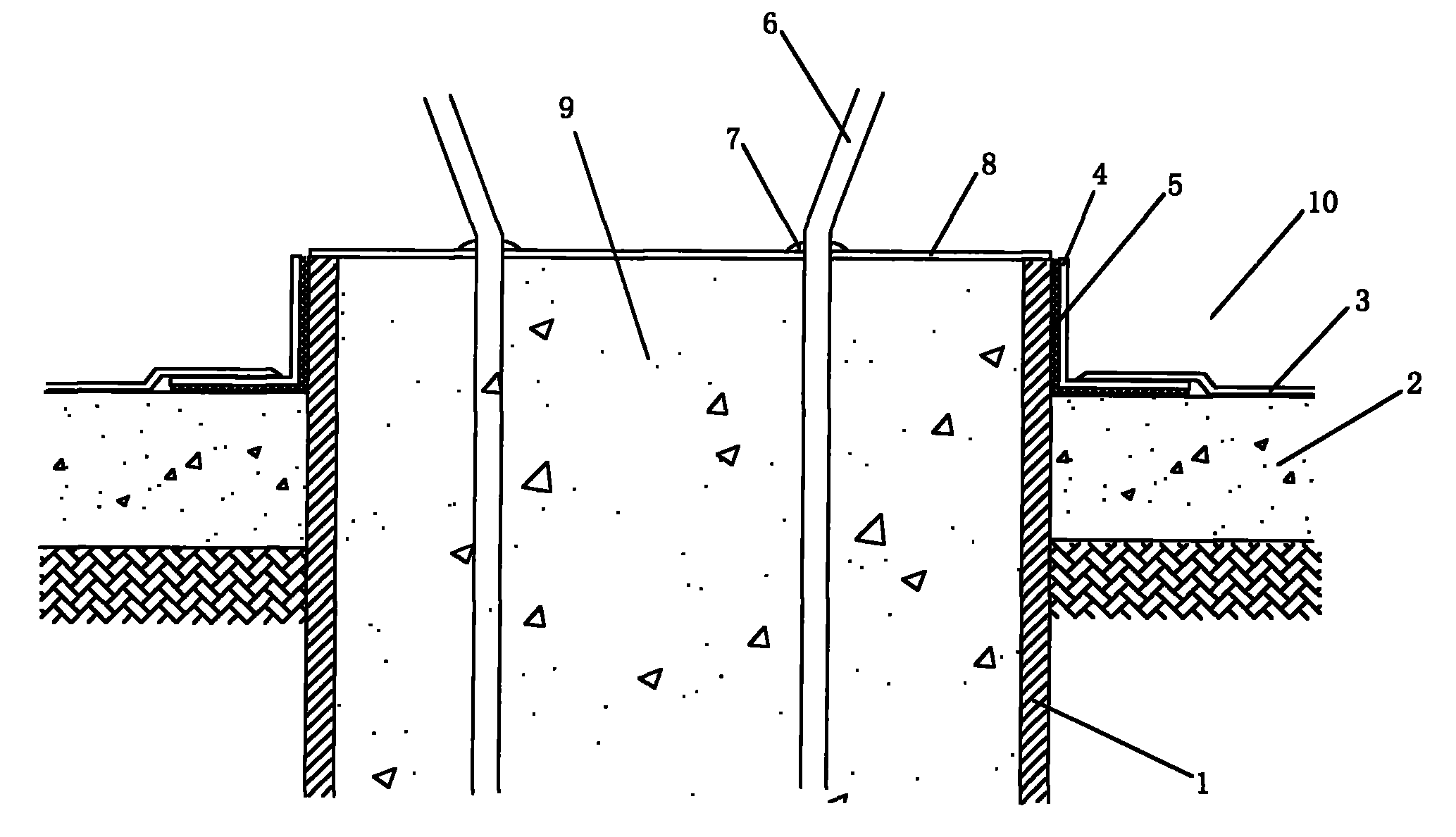

[0011] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0012] Precast piles generally include steel pipe piles and precast reinforced concrete piles, such as figure 1 Shown is a steel pipe pile, and the outer wall 1 of the pile head is a steel pipe; for a prefabricated reinforced concrete pile, the outer wall is concrete.

[0013] The waterproof method of the present invention, such as figure 1 Shown is the pile head section structure diagram of the steel pipe pile, including the steps:

[0014] Put the pile head waterstop 4 into the pile head; the pile head waterstop 4 is a cylindrical casing, which can be inserted into the pile head. The periphery of the pile head is generally cylindrical, and the inside is poured with concrete 9 and connecting steel bars 6;

[0015] Break open the inner ring of the pile head waterstop 4, inject epoxy resin adhesive 5, bond one wing of the pile head watersto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com