Multi-air-duct internal-absorption axial flow turbo fan

A turbo blower and multi-air channel technology, which is applied to mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of exhaust air volume volume constraints, exhaust air volume, and noise. , to achieve the effects of reducing material and production costs, increasing unit exhaust air volume, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail in the following with reference to the accompanying drawings and in the form of specific embodiments.

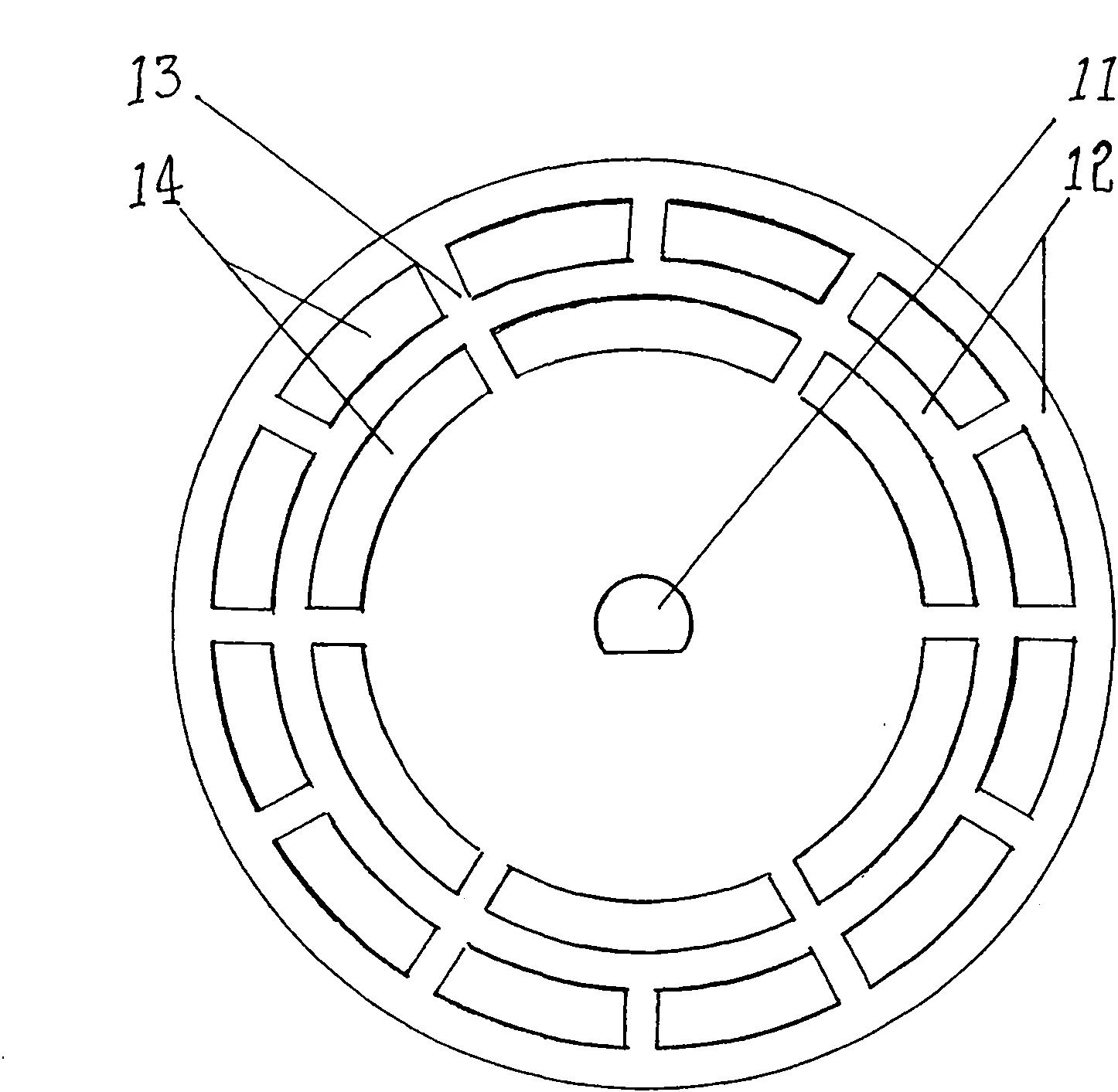

[0031] In this embodiment, the blade rings of the multi-air duct turbine (1) are temporarily set to two layers, but the number of layers of blade rings in actual production is not limited. , speed, volume and other factors.

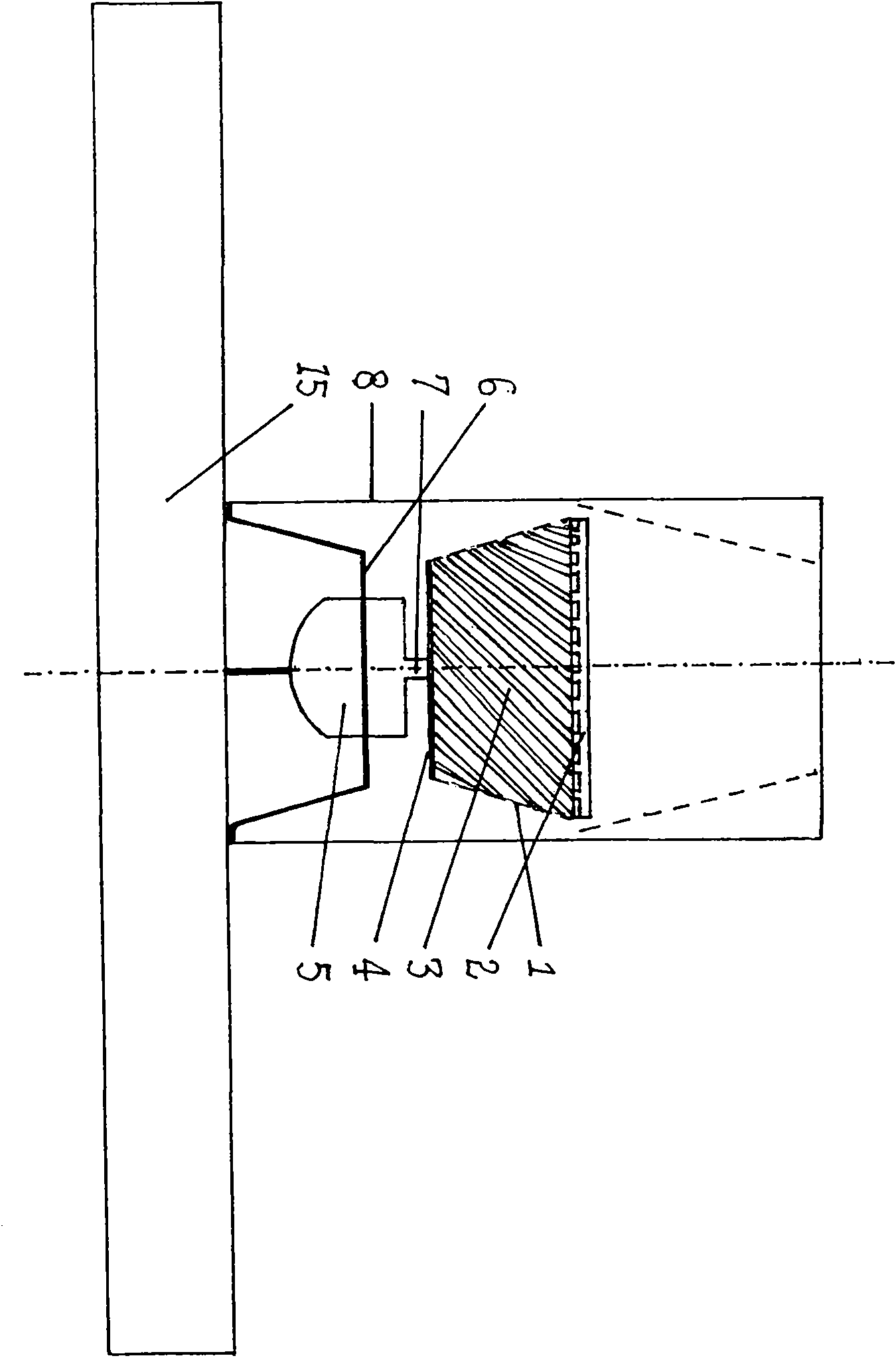

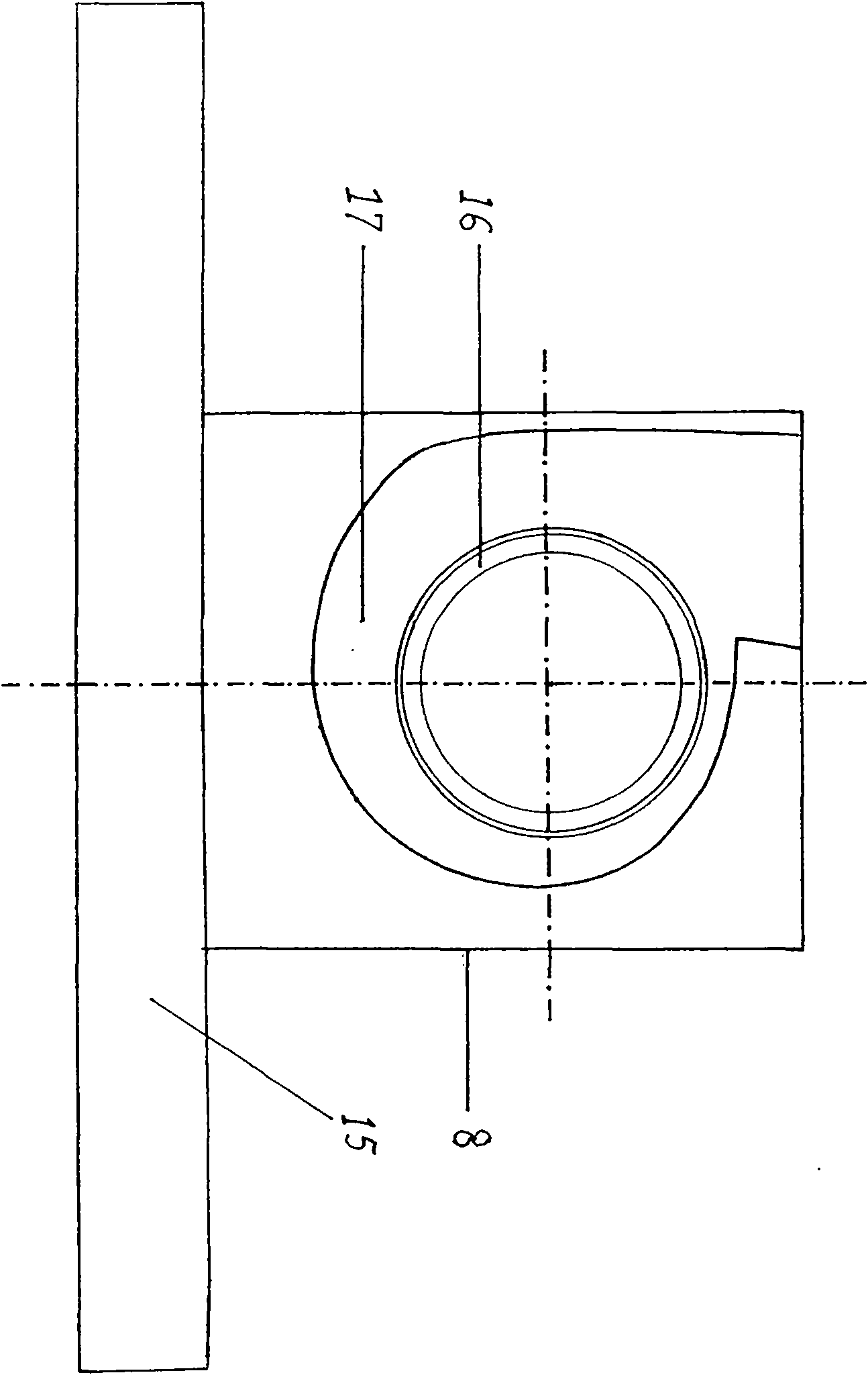

[0032] Such as figure 1 , image 3 , Figure 4 , Figure 5As shown, the motor bracket (6) is fixedly installed on the main body of the motor (5), and the multi-air duct turbine (1) is arranged on the motor output shaft (7), so that the motor output shaft (7) is mounted from the center of the installation chassis (4). The mounting holes (11) protrude and are fixed by fasteners to maintain a vertical state; the multi-air duct turbine (1) consists of a wheel surface fixing ring (2), angular fan blades (3), a mounting chassis (4), The outer fan blade ring (9), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com