Control device for water-coal-slurry burner

A technology of control device and burner, which is applied in the direction of burner, combustion method, control combustion, etc. It can solve the problems that cannot meet the actual needs of load change production, manual efficiency and speed difference, large fluctuation of medium temperature, etc., and achieve compensation Manual efficiency and speed difference and fully automatic unreliability and complex maintenance, prevent sedimentation and delamination, and reduce the effect of medium temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

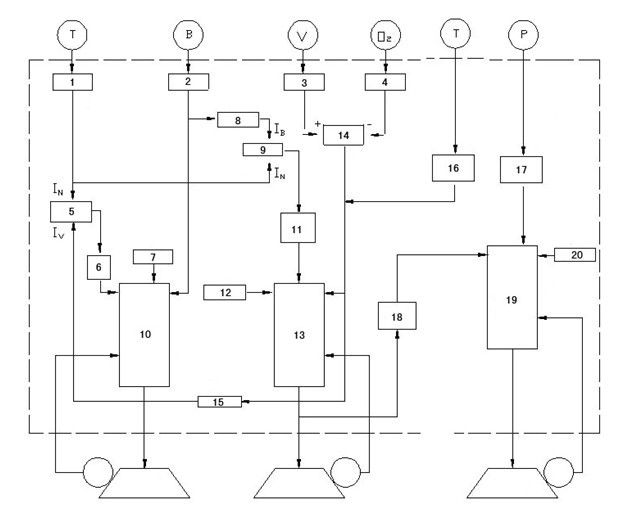

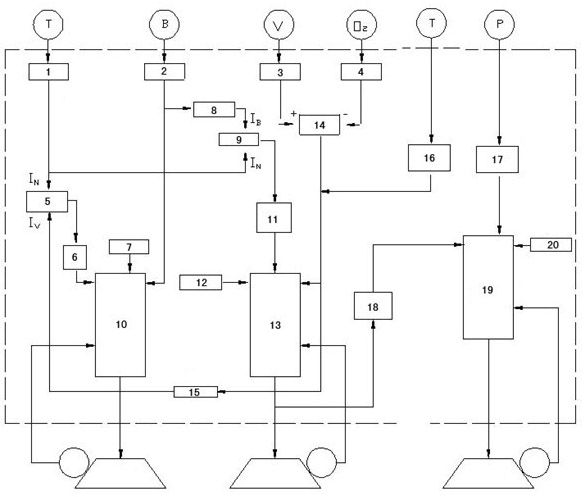

[0016] Such as figure 1 As shown, the coal-water slurry burner control device described in the embodiment of the present invention includes a slurry delivery pump speed control module 10, an air supply volume baffle control module 13 and an induced air volume baffle opening control module 19, and the slurry delivery The outside of the pump speed control module 10 is respectively connected with a heat medium temperature sensor 1, a slurry volume sensor 2, and an oxygen collector-7, wherein a small selection module 5 and a deviation module-6 are sequentially arranged on the line connected to the heat medium temperature sensor 1, The outside of the air supply baffle control module 13 is respectively connected with a deviation module two 11, an oxygen collector two 12 and a deviation module three 16, and the air supply baffle control module 13 is also connected to the air supply volume Sensor 3 and oxygen content sensor 4; in the structure described above, the outer side of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com