A device and method for using molten salt energy storage for distributed energy utilization

A technology of distributed energy and molten salt, which is applied in steam generation methods using heat carriers, energy storage, adsorption machines, etc., can solve the problems of natural gas air pollutants, difficult promotion, site restrictions, etc., and achieve comprehensive utilization of energy High efficiency, absorbing wind power abandonment, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

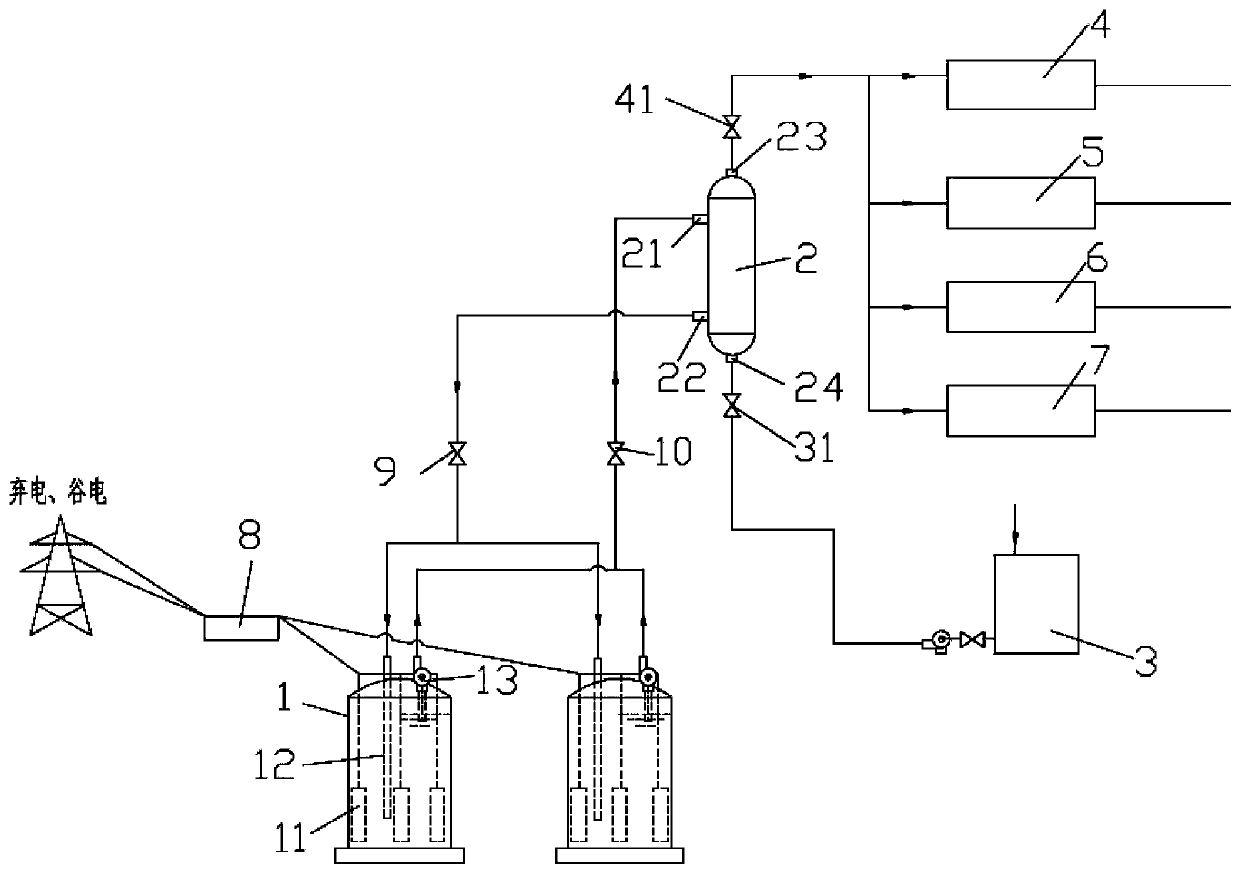

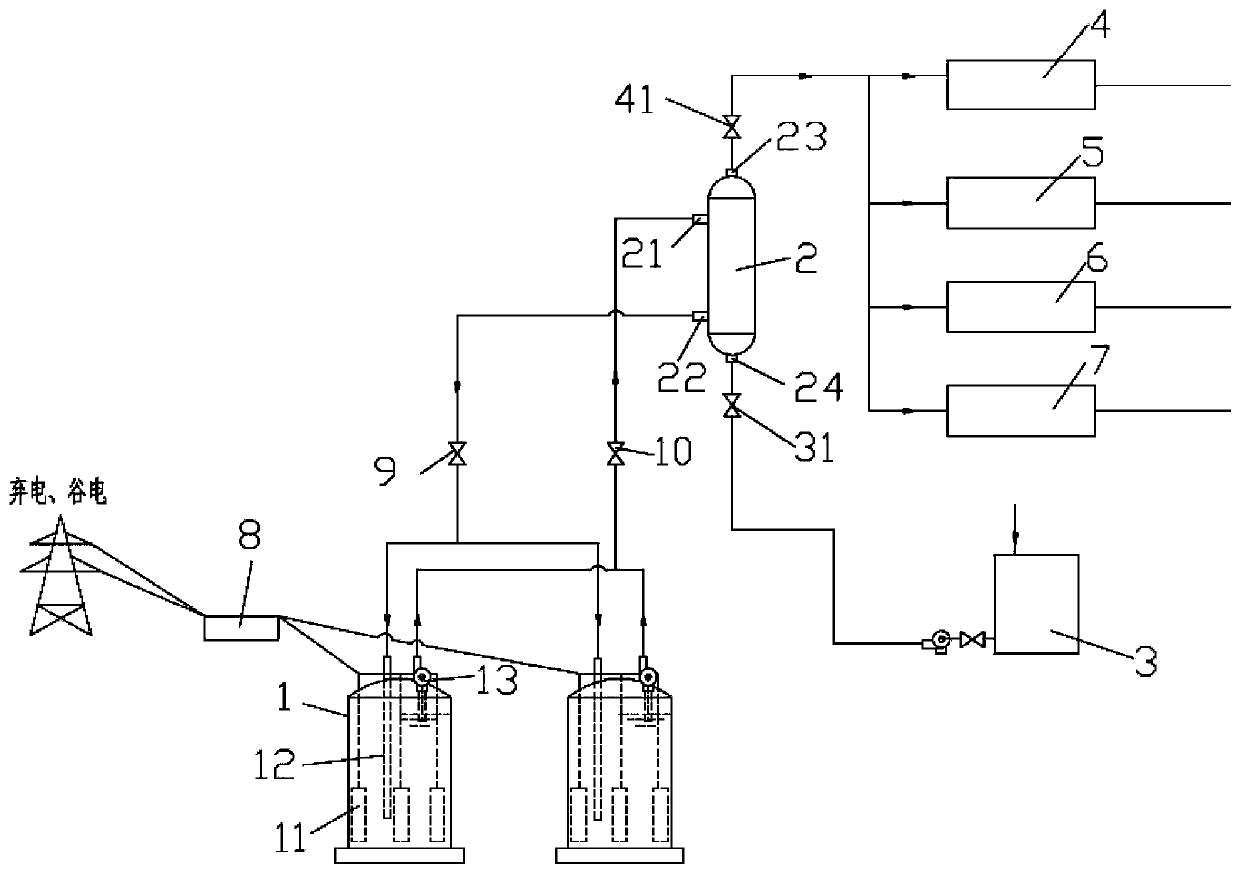

[0057] Such as figure 1 In the shown device, the steam generator 2 is a vertical shell-and-tube heat exchanger, and there are two molten salt heat storage tanks 1, and each molten salt heat storage tank 1 is equipped with three electric heaters 11, which are annular along the inner wall Evenly distributed in the molten salt heat storage tank 1.

[0058] When the device is used for distributed energy utilization of molten salt energy storage, electric signal processing equipment is used to convert the discarded electricity or off-peak electricity, and the electric heater 11 is used to electrically heat the molten salt in the molten salt heat storage tank 1 to 550°C, wherein the amount of molten salt in the molten salt heat storage tank 1 is guaranteed to have a safety height of 0.5 meters above the tank, and the molten salt is sodium nitrate;

[0059] Then, open the third valve to allow the cooling water to flow into the vertical shell-and-tube heat exchanger;

[0060] Open t...

Embodiment 2

[0064] The specific method is the same as in Example 1. The difference from Example 1 is that the device used in this example: there are 3 molten salt heat storage tanks 1, and 6 electric heaters 11 are provided in each molten salt heat storage tank 1. , distributed evenly in a ring shape along the inner wall in the molten salt heat storage tank. The molten salt in the molten salt heat storage tank 1 is electrically heated to 600°C.

[0065] In this embodiment, the efficiency of the electric heating energy storage part is 97.1%, the energy utilization rate of the heat output to the combined cooling, heating and power supply part is 81%, and the comprehensive energy utilization rate can reach 71.9%.

Embodiment 3

[0067] The specific method is the same as in Example 1. The difference from Example 1 is that the device used in this example: one molten salt heat storage tank 1, each molten salt heat storage tank 1 is provided with 6 electric heaters 11 , distributed uniformly in a ring shape along the inner wall in the molten salt heat storage tank 1 . The molten salt in the molten salt heat storage tank 1 is electrically heated to 650°C.

[0068] In this embodiment, the efficiency of the electric heating energy storage part is 97.5%, the energy utilization rate of the heat output to the combined cooling, heating and power supply part is 83%, and the comprehensive energy utilization rate can reach 72.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com