Intelligent electronic balance

An electronic balance, intelligent technology, applied in measuring devices, instruments, weighing and other directions, can solve problems such as increasing the difficulty of operation, increasing production costs, etc., to achieve the effect of reasonable structure, high accuracy, and reduction of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

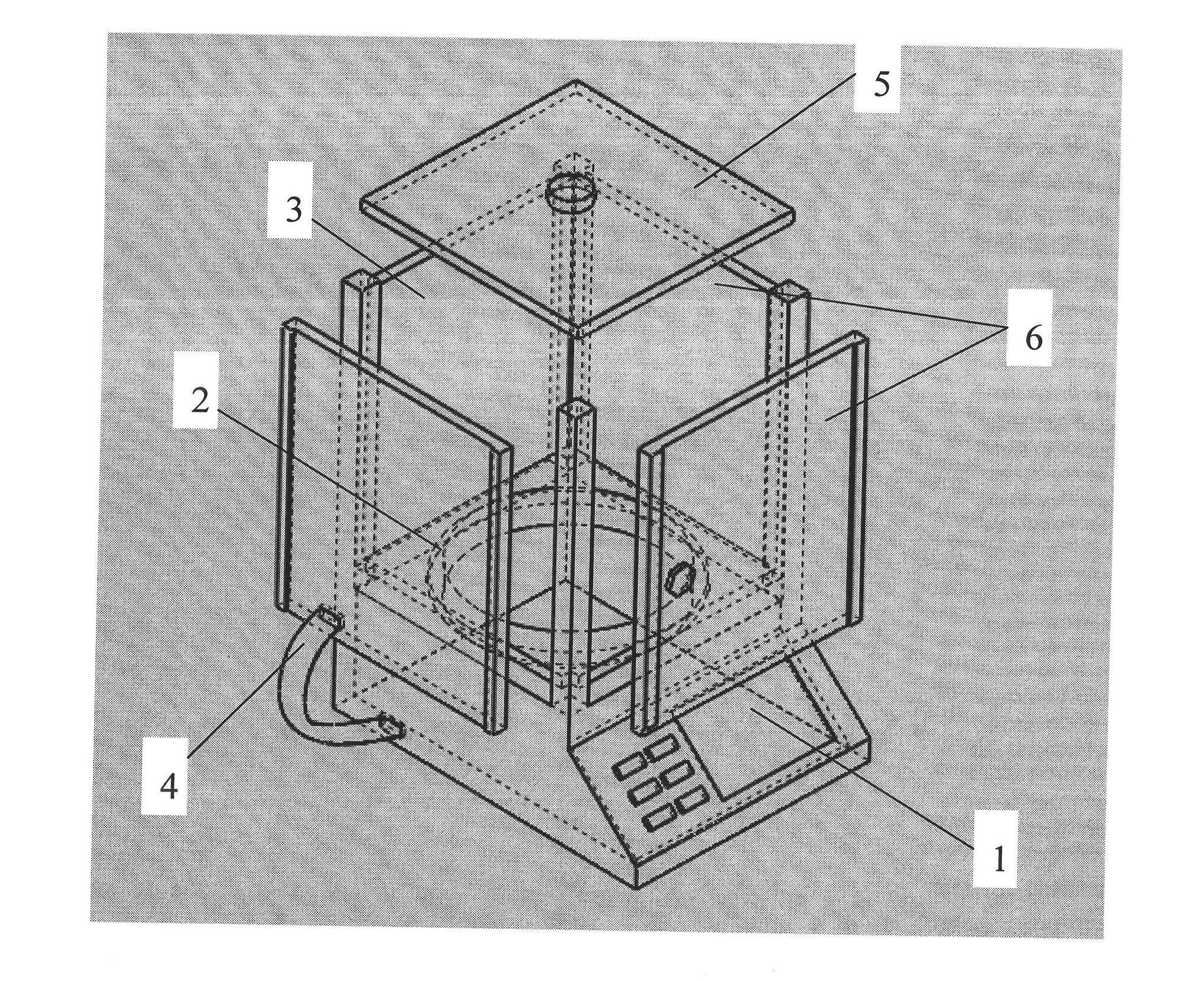

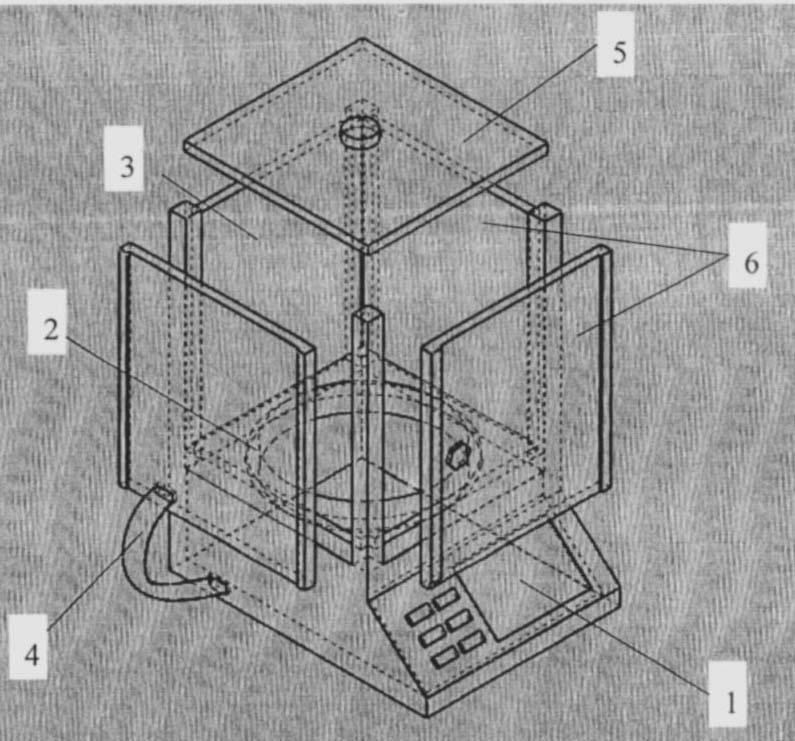

Image

Examples

Embodiment 1

[0020] The combined weighing box is disassembled and assembled, and the microwave heating functional side plate is installed, which can realize the microwave heating of the weighing object, and the temperature range of the lifting object is 0.5°C-50°C. Through computer control, the weighing object can be accurately weighed at a certain temperature. The actual quality value of the interval; at the same time, this function can detect the quality change of the material after the temperature changes. If the material quality change value exceeds the applicable range due to the temperature change, the material is a waste product, which can eliminate hidden dangers and improve safety. coefficient.

Embodiment 2

[0022] The combined weighing box is disassembled and assembled, and the cooling quick-freezing functional side plate is installed, which can realize the freezing and cooling of the weighing object, and the temperature range of the lowering object is 0.5°C-30°C. Through computer control, the weighing object can be accurately weighed at a certain temperature. The actual quality value of the interval; at the same time, this function can detect the quality change of the material after the temperature changes. If the material quality change value exceeds the applicable range due to the temperature change, the material is a waste product, which can eliminate hidden dangers and improve safety. coefficient.

Embodiment 3

[0024] The combined weighing box can be disassembled and assembled, and the physical dehumidification functional side plate is installed, which can realize the control of the humidity percentage of the weighing object, and reduce the humidity percentage from 0.05% to 5%. Through computer control, it can be accurately reduced The humidity content of the object reduces the dehumidification process and reduces the production cost; at the same time, this function can detect the quality change of the material during the humidity change process, and analyze the influence of the material humidity on the quality. If the impact is large, the material is waste. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com