Device for testing high hydrostatic pressure and acoustic pressure sensitivity of hydrophone

A sensitivity test and high hydrostatic pressure technology, which is applied in the field of sensing, can solve problems such as inability to perform high hydrostatic pressure sensitivity tests, and achieve the effect of reducing production costs and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

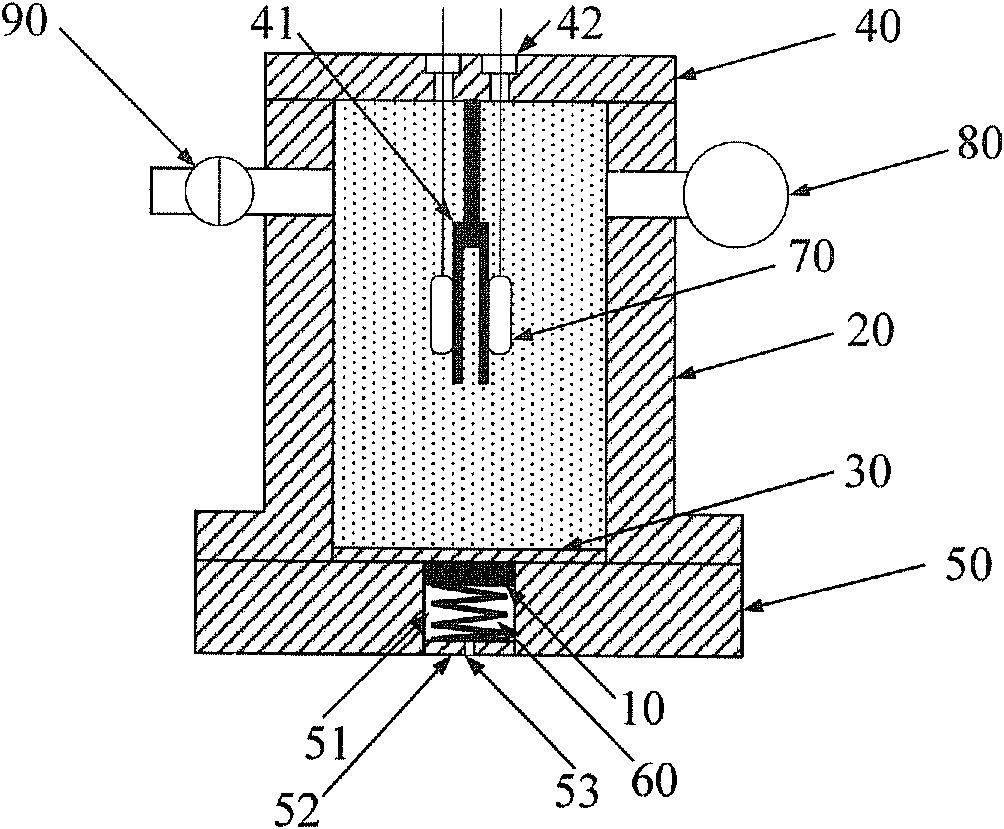

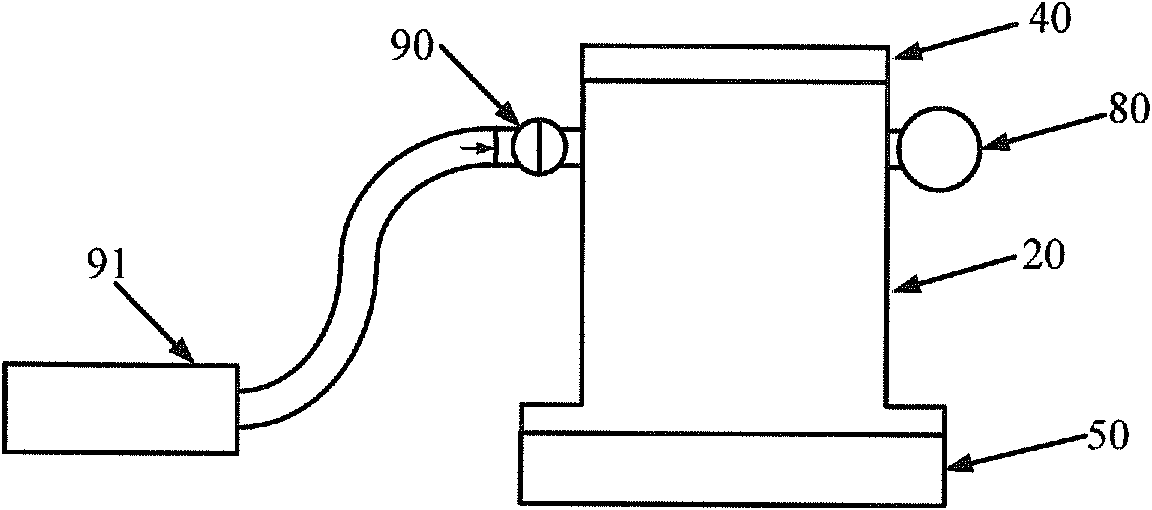

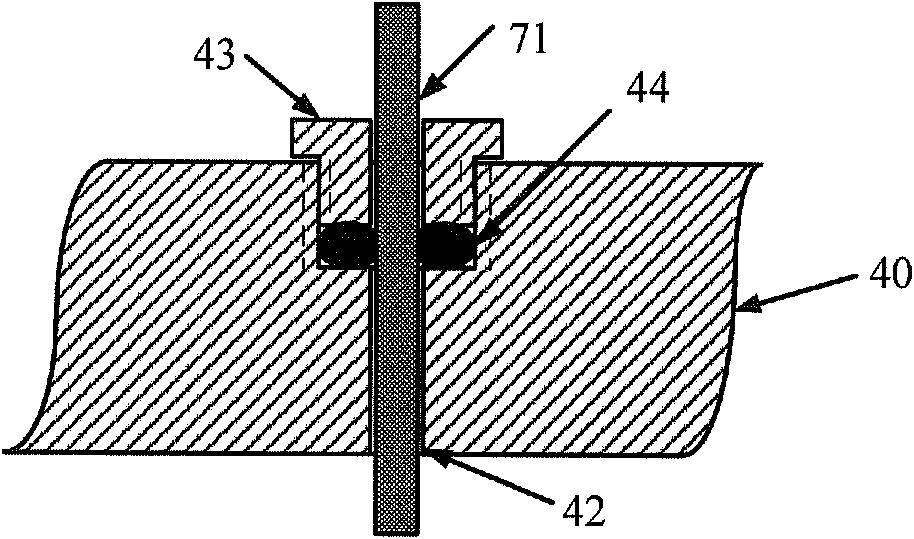

[0034] Such as Figure 1 ~ Figure 3 As shown, the hydrophone high hydrostatic pressure sound pressure sensitivity testing device includes: an exciter 10 for generating a vibration signal; a liquid column cylinder 20 as a container for testing; a thin plate 30 installed at the bottom of the liquid column cylinder 20 for The vibration signal is converted into a sound pressure signal in the liquid; the sealing cover 40 installed on the top of the liquid column cylinder 20 is used to form a closed container with the liquid column cylinder 20 and the thin plate 30; the base 50 installed under the liquid column cylinder 20, Used to limit the vibration direction of the vibrator 10 and support the thin plate 30 to prevent the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com