Position controller with acceleration and current feedforward for heavy-load robot

A technology of current feedforward and acceleration, which is applied in the direction of control using feedback, can solve problems such as failure to meet application requirements, achieve good control performance, avoid large calculations, and solve the effect of dynamic multi-axis coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

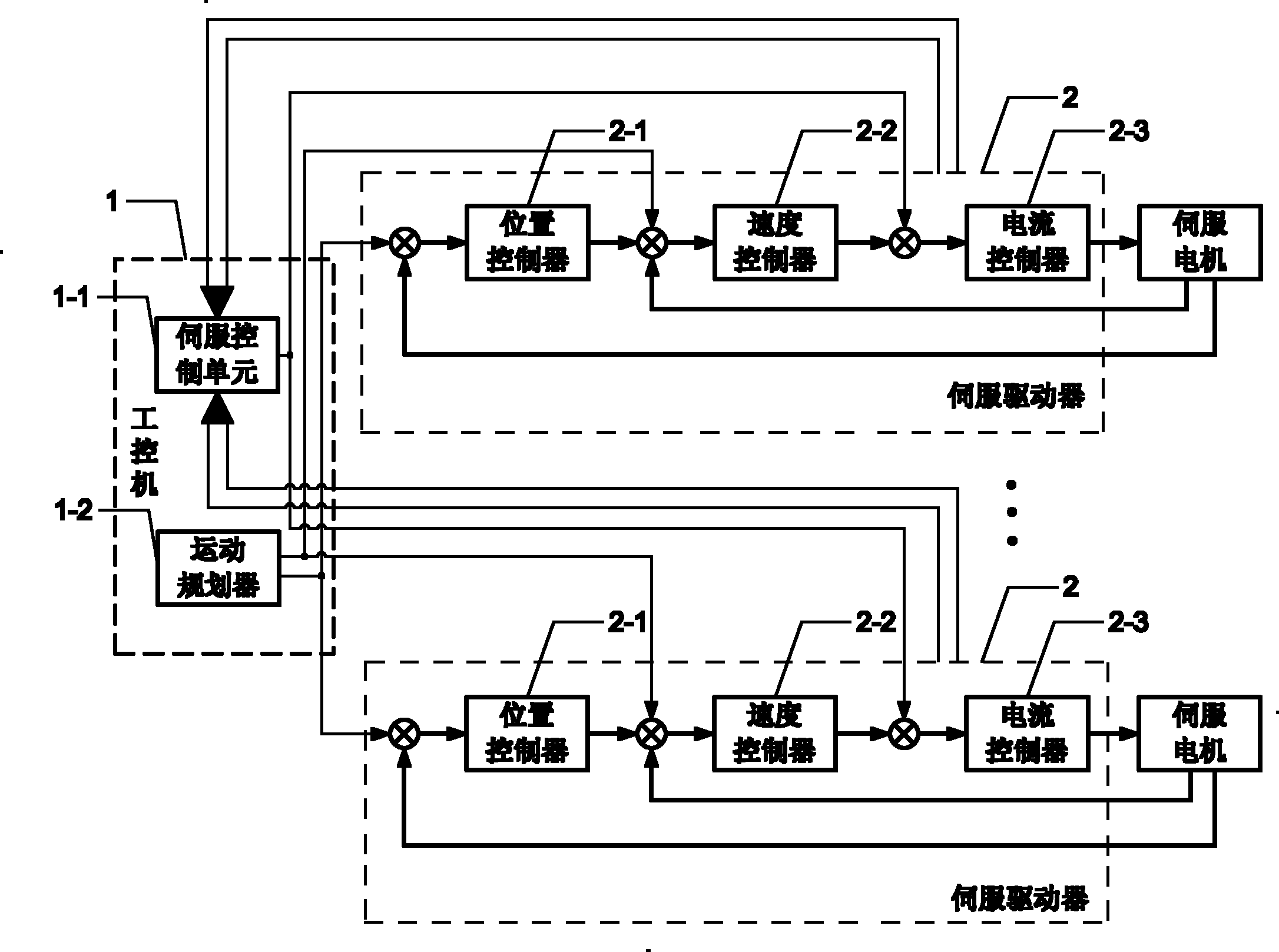

[0017] Specific implementation mode one: the following combination figure 1 Describe the present embodiment, the heavy-duty robot described in the present embodiment has the position controller of acceleration and current feed-forward, and it comprises industrial computer 1 and n servo drives 2;

[0018] The industrial computer 1 includes a servo control unit 1-1 and a motion planner 1-2;

[0019] The servo driver 2 includes a position controller 2-1, a speed controller 2-2 and a current controller 2-3;

[0020] The n position signals output by the motion planner 1-2 are respectively sent to each servo driver 2; the n speed feed-forward signals output by the motion planner 1-2 are respectively sent to each servo driver 2; the servo control unit 1-1 outputs n current feedforward signals are given to each servo driver 2 respectively; the drive signal of each servo driver 2 is fed back to the servo control unit 1-1, and the drive signal includes a position feedback signal, a spe...

specific Embodiment approach 2

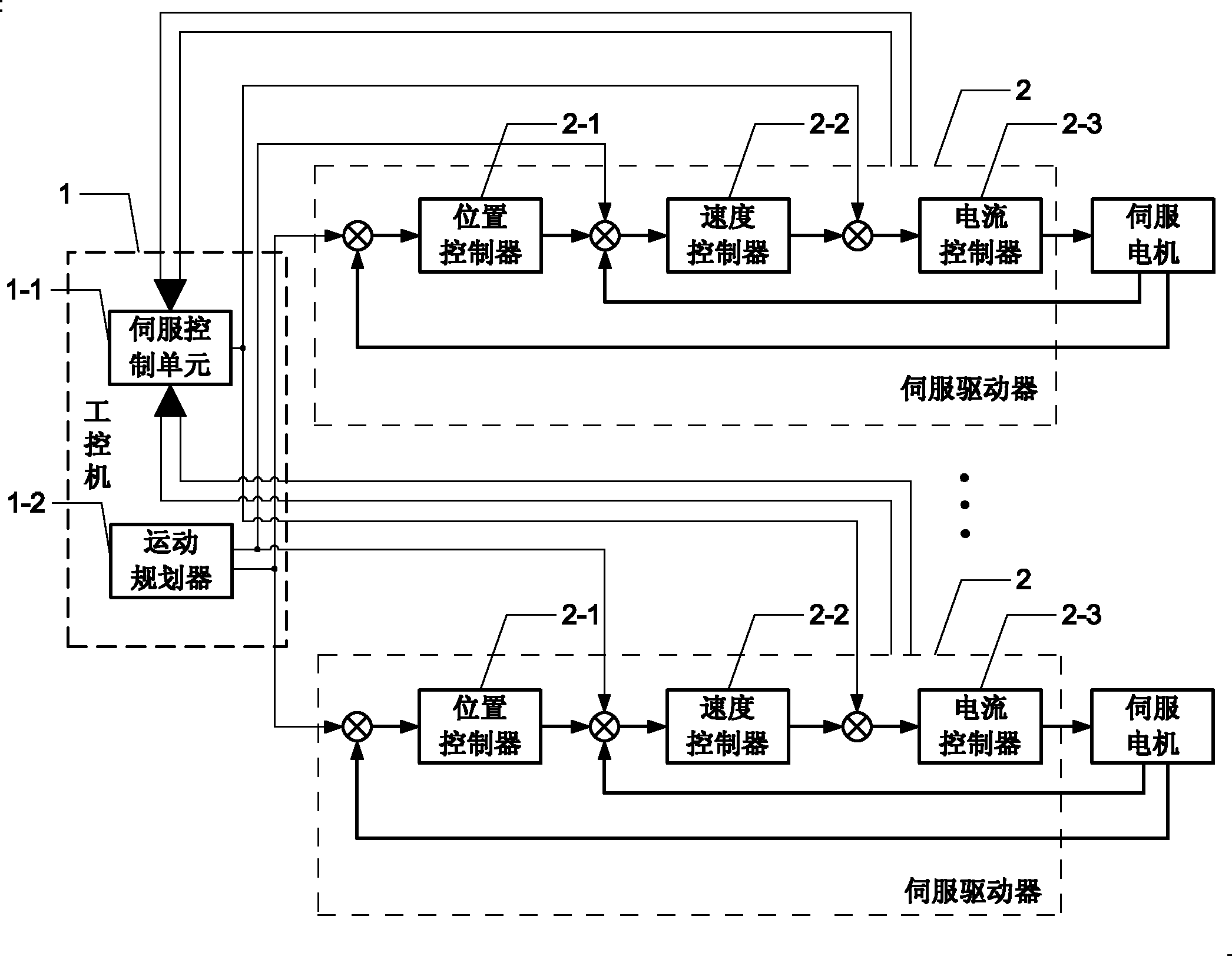

[0024] Specific implementation mode 2: This implementation mode provides a specific example, n=6, that is, the controller has 6 servo drives 2 . The position controller with acceleration and current feed-forward of described heavy load robot, it comprises industrial computer 1 and 6 servo drives 2;

[0025] The industrial computer 1 includes a servo control unit 1-1 and a motion planner 1-2;

[0026] The servo driver 2 includes a position controller 2-1, a speed controller 2-2 and a current controller 2-3;

[0027] The position signal output by the motion planner 1-2 is sent to each servo driver 2 respectively; the speed feedforward signal output by the motion planner 1-2 is sent to each servo driver 2 respectively; the current feedforward signal output by the servo control unit 1-1 To each servo driver 2 respectively; the driving signal of each servo driver 2 is fed back to the servo control unit 1-1, and the driving signal includes a position feedback signal, a speed feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com