Controlled and monitored width-adjusting servo system of brushless torque motor

A servo system and brush force technology, applied in the circuit field, can solve the problems that the servo system does not have the ability to interface with the bus, has a low degree of automation, and relies on testers, etc., and achieves the advantages of simple design, high heating power, and reduced AC magnetic field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

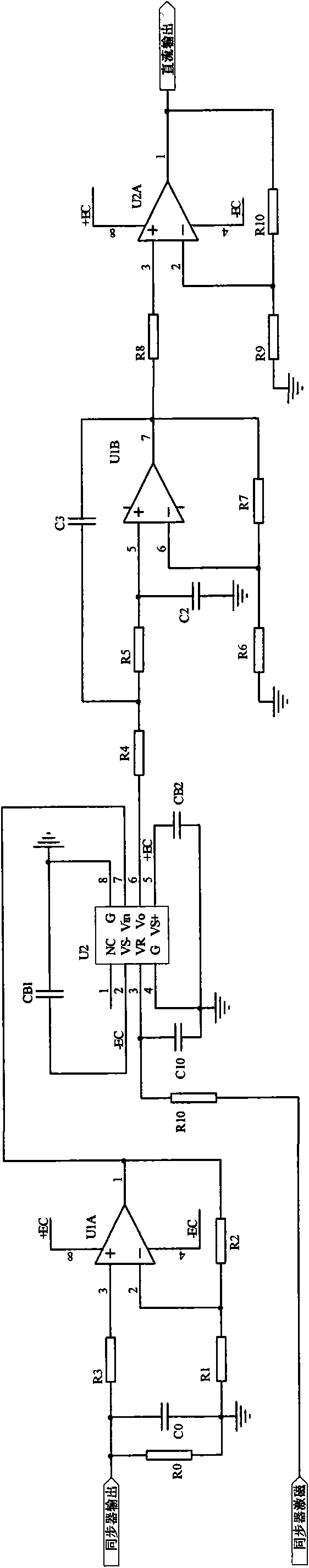

[0024]The system power supply includes ±12V (code-named ±EC) signal power supply; +5V (code-named VD5) is logic power supply, +28V (code-named VD28) power supply; +5V (code-named VCC) bus control power supply; +5V (code-named VD28) power supply; code-named M05)I 2 C monitors the power supply. Each power supply is isolated from each other.

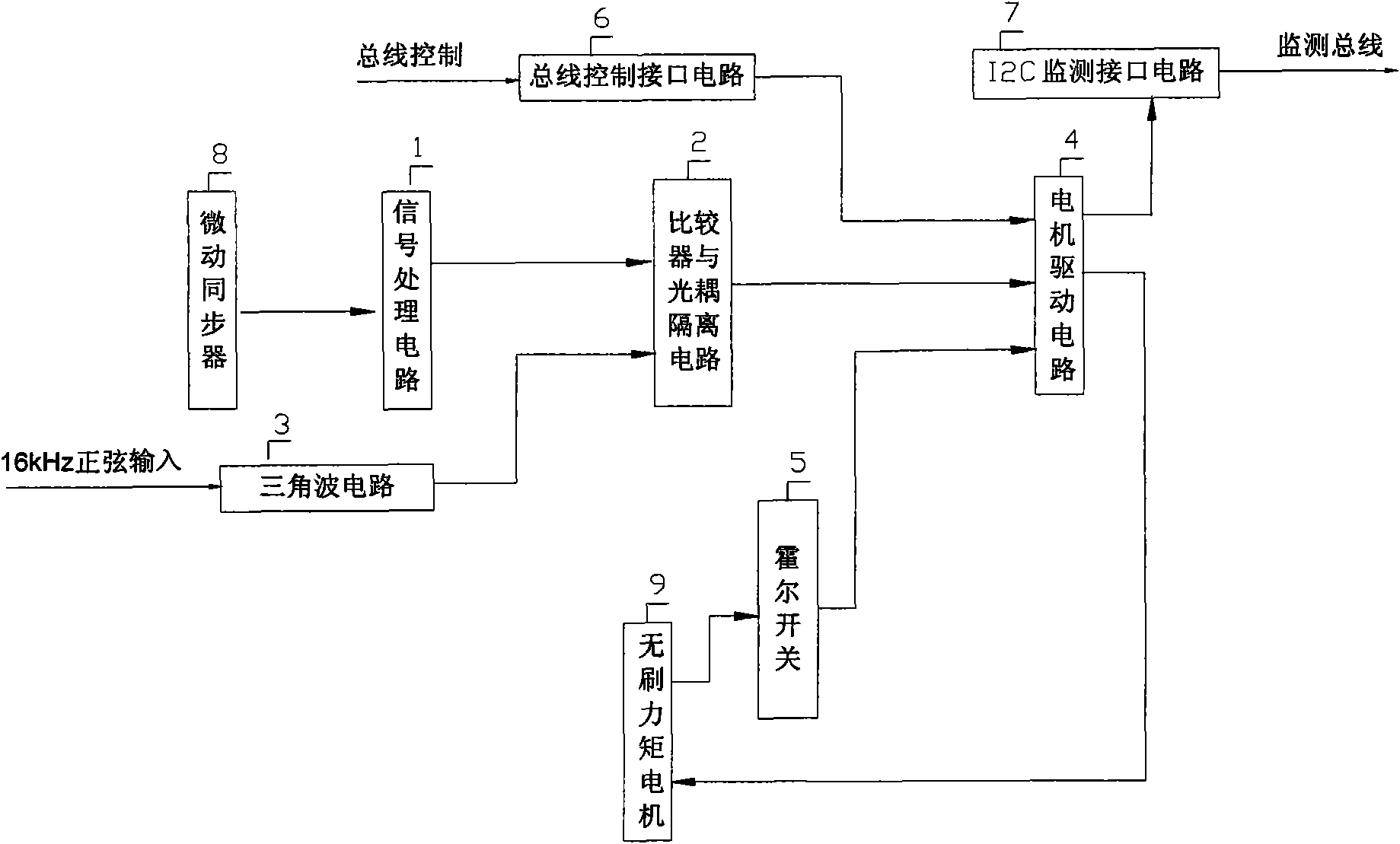

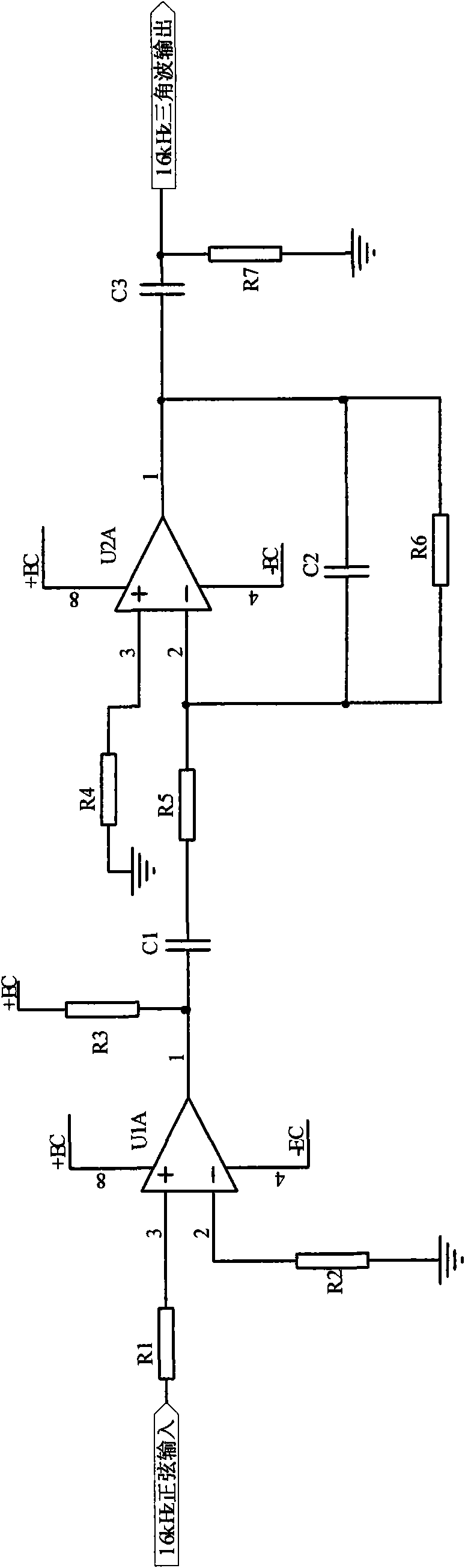

[0025] The specific implementation of the system will be described below in conjunction with the accompanying drawings. figure 1 It is a block diagram of a controllable and monitorable brushless torque motor width adjustment servo system, including signal processing circuit 1, comparator and optocoupler isolation circuit 2, triangular wave circuit 3, motor drive circuit 4, Hall switch 5, and bus control interface Circuit 6, I 2 C monitoring interface circuit 7, micro-synchronizer 8, brushless torque motor 9. The micro-synchronizer outputs an AC signal proportional to the angle, and through the signal processing circuit, triangular wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com