Liquid densitometer

一种浓度计、液体的技术,应用在悬浮液和多孔材料分析、仪器、分析材料等方向,能够解决测定误差、不能避免测定误差、原材料污染配管电阻等问题,达到误差稳定、误差小、稳定测定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

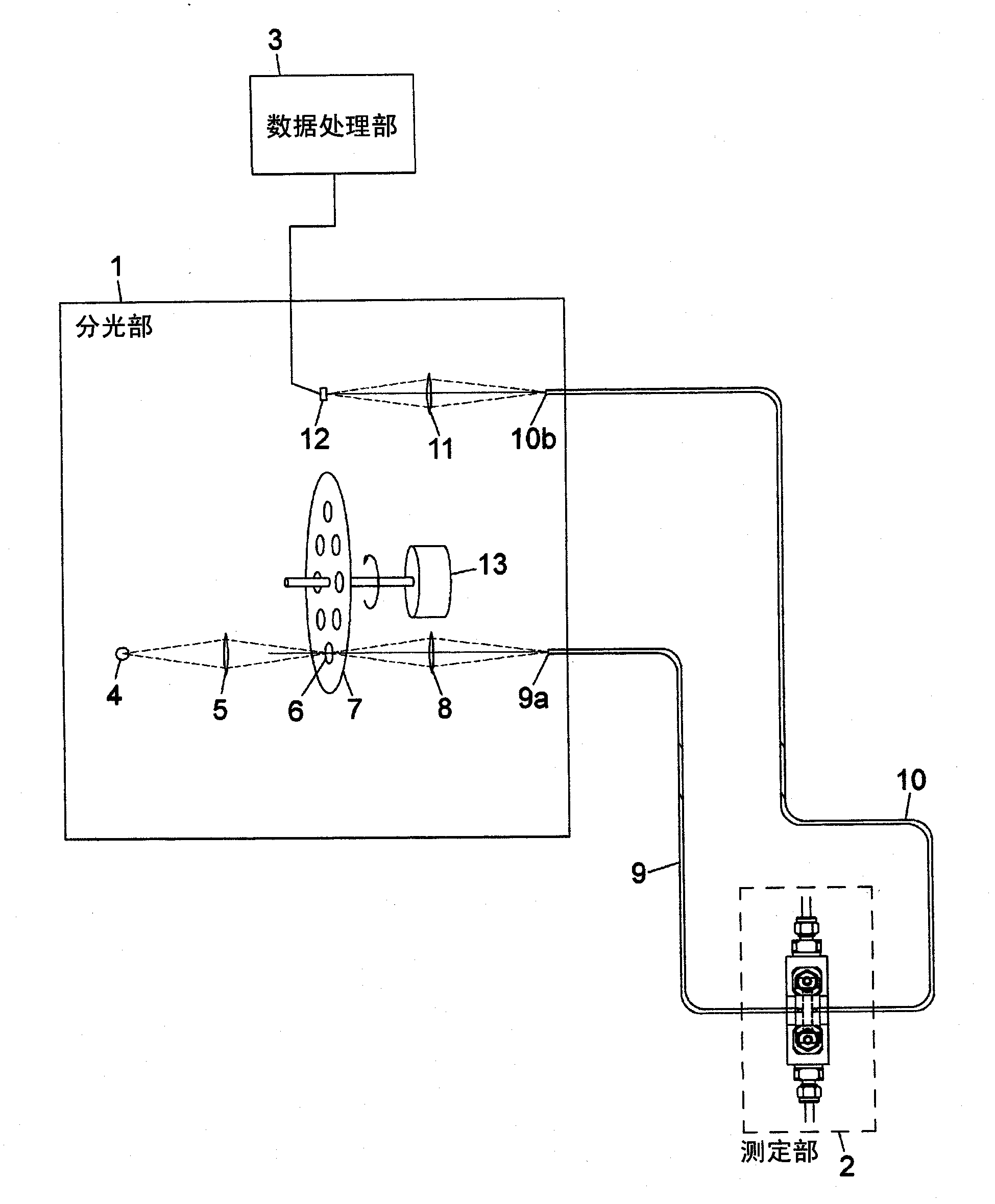

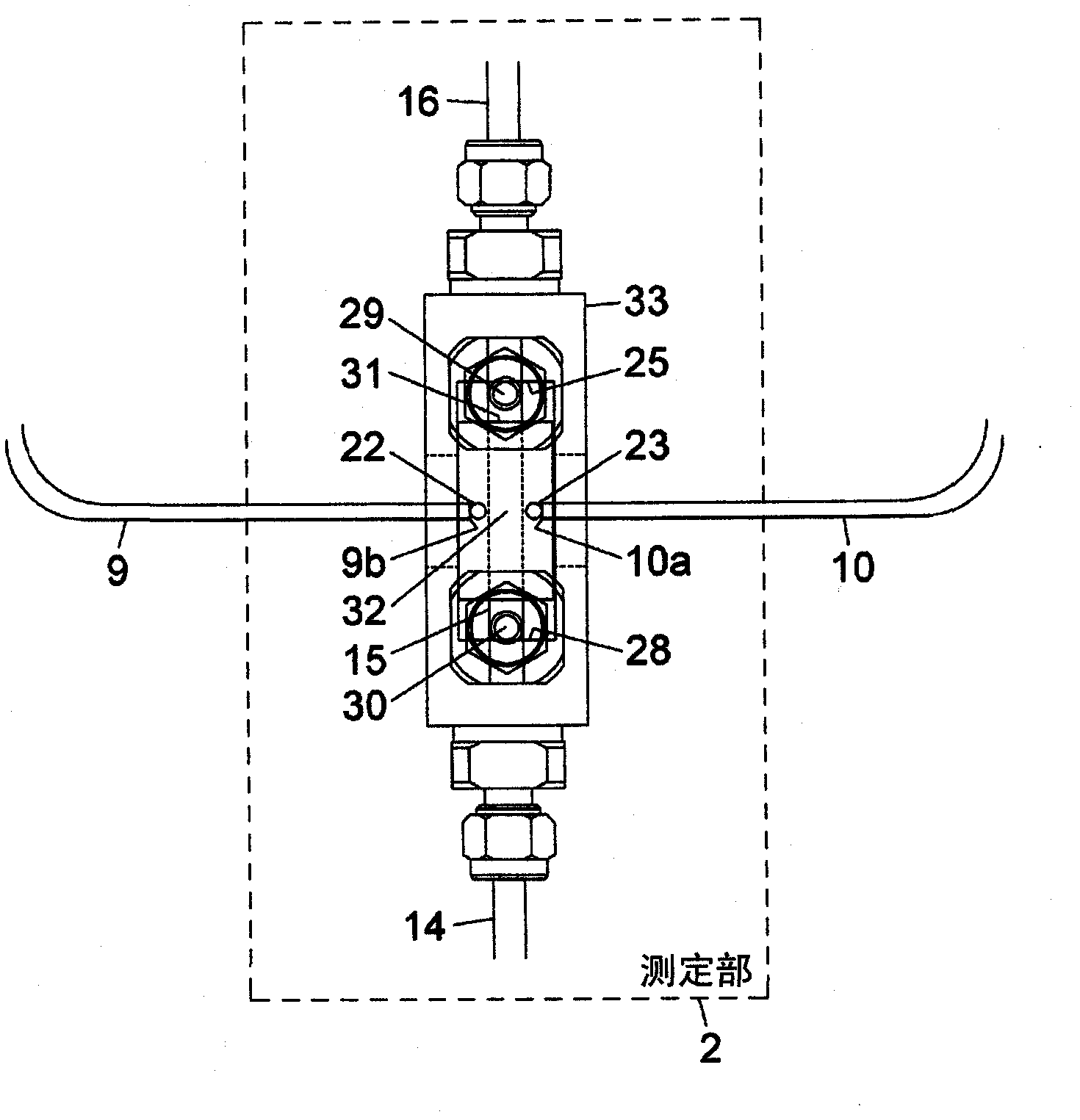

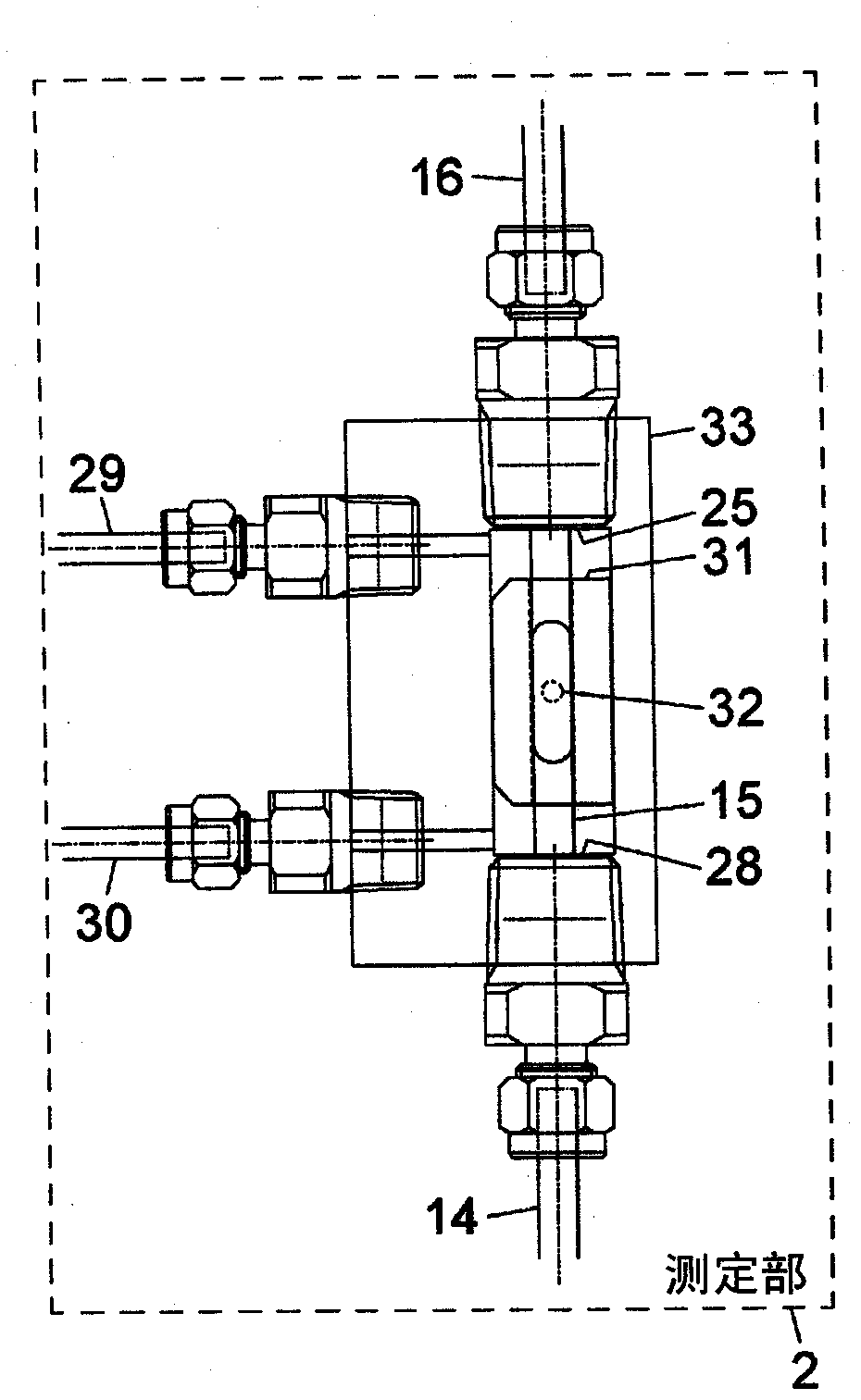

[0050] figure 1 It is a figure which briefly shows an Example. figure 2 , image 3 It is a figure which shows the measurement part of this Example. figure 2 is a plan view of the measurement unit, image 3 It is a side view of the measurement unit. Figure 4 and Figure 5 It is a cross-sectional view for explaining the operation of the measurement unit of this embodiment.

[0051] Such as figure 1 As shown, the liquid concentration meter is substantially composed of a spectroscopic part 1 , a measuring part 2 , and a data processing part 3 .

[0052] First, a specific configuration of the spectroscopic unit 1 will be described.

[0053] The spectroscopic unit 1 is provided with a tungsten lamp 4 as a light source, a convex lens 5 , a rotating disc 7 including eight interference filters 6 , a convex lens 8 , a convex lens 11 , and a light receiving element 12 . The light emitted by the tungsten filament lamp 4 is collected by the convex lens 5 and passes through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com