Method for quickly measuring content of five rare earth elements in edible packing material

A technology of packaging materials and rare earth elements, which is applied in the field of determination of edible packaging materials, can solve the problems of affecting human health, high test background, and large amount of reagents, so as to simplify the pre-processing and testing process, overcome low sensitivity, and save testing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: the mensuration of five kinds of rare earth element contents of La, Ce, Pr, Sm and Nd in edible packaging material

[0040] The method for measuring the content of five rare earth elements La, Ce, Pr, Sm and Nd in edible packaging materials, the specific steps of the method adopted are as follows:

[0041] (1) Accurately weigh 0.5000 g of the uniformly prepared gelatin capsule shell, place it in a polytetrafluoroethylene digestion tank cleaned by acid boiling, add 8 mL of nitric acid, and conduct microwave digestion procedure for heating and digestion.

[0042] The microwave digestion program is as follows: power 1200W, heat up for the first time, raise the temperature to 80°C within 4min, and stay at 80°C for 3min; 100°C, and stay at 100°C for 2 minutes; carry out the third heating, from 100°C to 120°C within 1 minute, and stay at 120°C for 2 minutes; carry out the fourth heating , from 120°C to 180°C within 2 minutes, and stay at 180°C for 15 minutes....

Embodiment 2

[0048] Embodiment two: the preparation of standard solution

[0049] 1. Experimental process

[0050] (1) The standard working solution is obtained by diluting the national standard mother solution of La, Ce, Pr, Nd, Sm elements (National Standard Material Research Center) 1000mg / L step by step, according to the content of La, Ce, Pr, Nd, Sm in the sample, the preparation is different Concentration of the standard working solution, the preparation of La, Ce, Pr, Nd, Sm mixed standard working solution concentration: 1.00, 10.00, 20.00, 50.00μg / L.

[0051] Use ICP-MS to measure and draw a standard curve, and the correlation coefficient of the measurement results must be above 0.999.

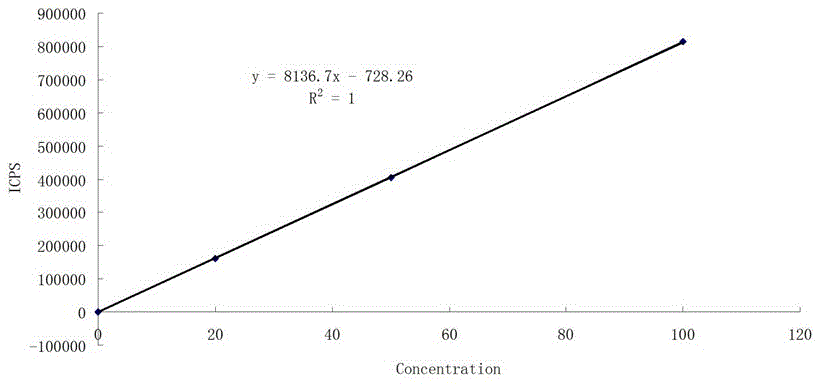

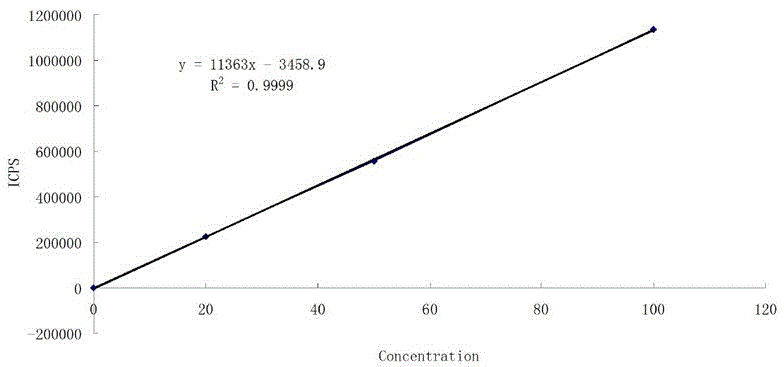

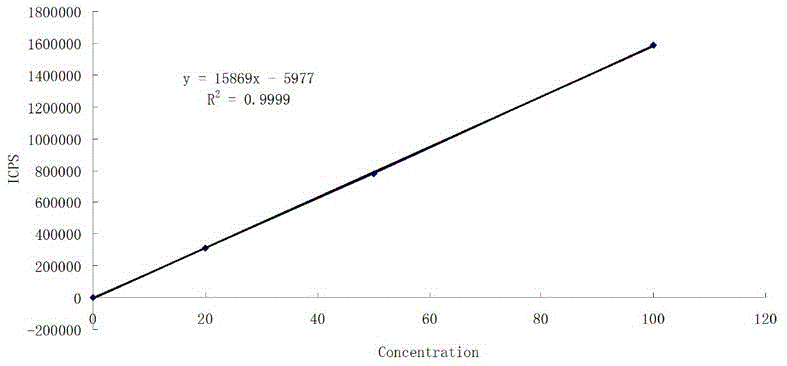

[0052] (2) Drawing of standard working curves of La, Ce, Pr, Nd, Sm elements

[0053] Draw the curve with the concentration of the standard solution of each element (in μg / L) as the abscissa and the corresponding absorbance as the ordinate.

[0054] 2. Experimental results

[0055] For the stan...

Embodiment 3

[0058] Embodiment 3: Elimination of Interference

[0059]The incomplete dissociation of the matrix during the sample measurement or the recombination of dissociated elements in the plasma tail flame will form refractory oxide ions or hydroxide ions, which will interfere with the determination, while the interference of oxides and hydroxides of rare earth elements more serious. By tuning the instrument parameters so that the ratio of CeO / Ce is 0.72%, the oxide interference can be basically eliminated. In addition, the matrix effect and interface effect are eliminated by adding an internal standard online. The selected internal standard element is not interfered by isobaric overlapping or polyatomic ions, or interferes with the isotope of the measured element. The content is very little or even none, and the selected internal standard should be close to the mass number of the element to be measured. In is used as the internal standard element to correct the signal drift of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com