Welding wire machine

A wire bonding machine and heating block technology, which is applied in the field of wire bonding machines, can solve the problems of troublesome replacement of heating blocks, expensive heating blocks, and reduced machine efficiency, etc., and achieves simple structure, preheating speed block, and enlarged heating area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be further described in detail below.

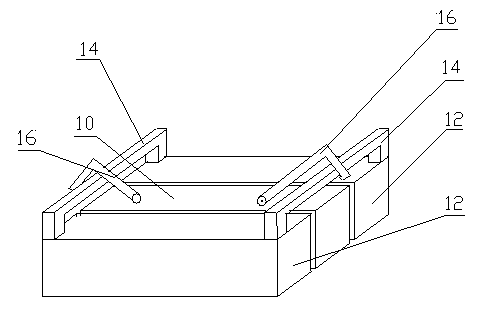

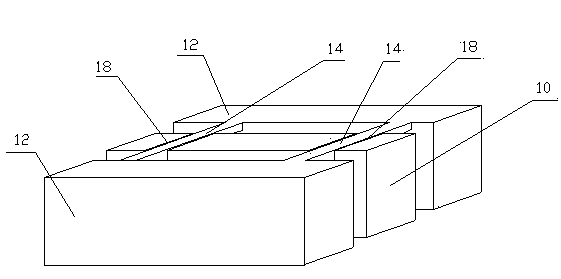

[0022] Such as figure 1 As shown, the wire bonding machine according to the first embodiment of the present invention has a preheating module on it, and the preheating module mainly includes a preheating plate (not shown) and a heating plate arranged under the preheating plate to heat the preheating plate. The heating block 10, the workpiece to be welded (not shown) is placed on the preheating plate for preheating. The area of the upper surface of the preheating plate is larger than the area of the upper surface of the heating block 10 . The heating block 10 is elongated, and two sides of the heating block 10 are provided with elongated heat transfer blocks 12 made of metal with good thermal conductivity. The upper surface of the heat transfer block 12 is located on the same plane as the upper surface of the heating block 10, so that it is in close contact with the preheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com