Pipe clamp with vibration absorption structure for automobile

A vibration-damping structure and pipe clamp technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problem that the insertion and extraction force of projection welding bolts cannot be adjusted, the vibration and noise of the whole vehicle are high, and the axial direction of the pipe can not be adjusted. To avoid problems such as moving, to achieve the effect of convenient and reliable assembly, adjustable vibration damping effect, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

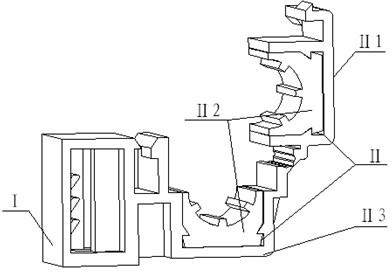

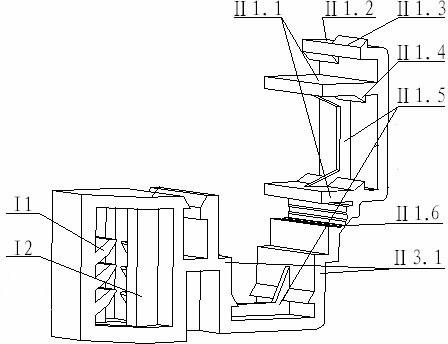

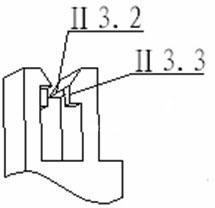

[0021] The following set of drawings describe the structure of the pipe clamp in detail:

[0022] see figure 1 , The present invention consists of the installation part I and the clamping part II. The installation part I is a frame structure with bolt installation holes, and there are guide teeth I1 and guide columns I2 in the holes. The clamping part Ⅱ is composed of the pipe clamp cover Ⅱ1, the vibration damping pad Ⅱ2 and the pipe clamp seat Ⅱ3. The installation part Ⅰ, the pipe clamp cover Ⅱ1, and the pipe clamp seat Ⅱ3 are connected as a whole through injection molding. The vibration damping pad Ⅱ2 is installed on the pipe clamp cover Ⅱ1 and the pipe clamp seat Ⅱ3 by inlaying, and the pipe clamp cover Ⅱ1 and the pipe clamp seat Ⅱ3 are buckled. to form a clamping hole.

[0023] The matching structure of the installation part Ⅰ and the fixing bolt 1 is detailed in Figure 4 and Figure 5 . The guide teeth Ⅰ1 are symmetrically distributed on both side walls of the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com