High-temperature high-pressure adsorption tester

A high-temperature, high-pressure, tester technology, applied in measuring devices, scientific instruments, suspension and porous material analysis, etc., can solve the problems of laborious, low experimental efficiency, time-consuming adsorption tanks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Taking a high temperature and high pressure adsorption tester as an example, the present invention is further described in detail.

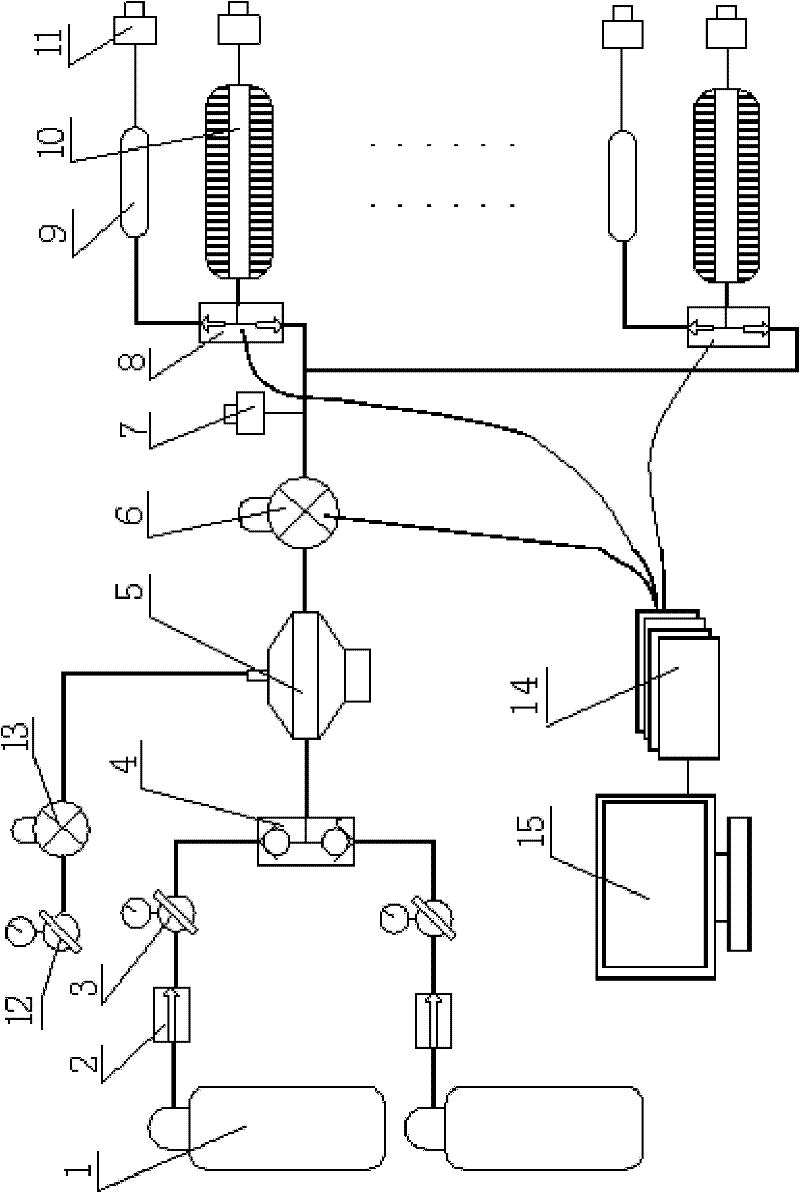

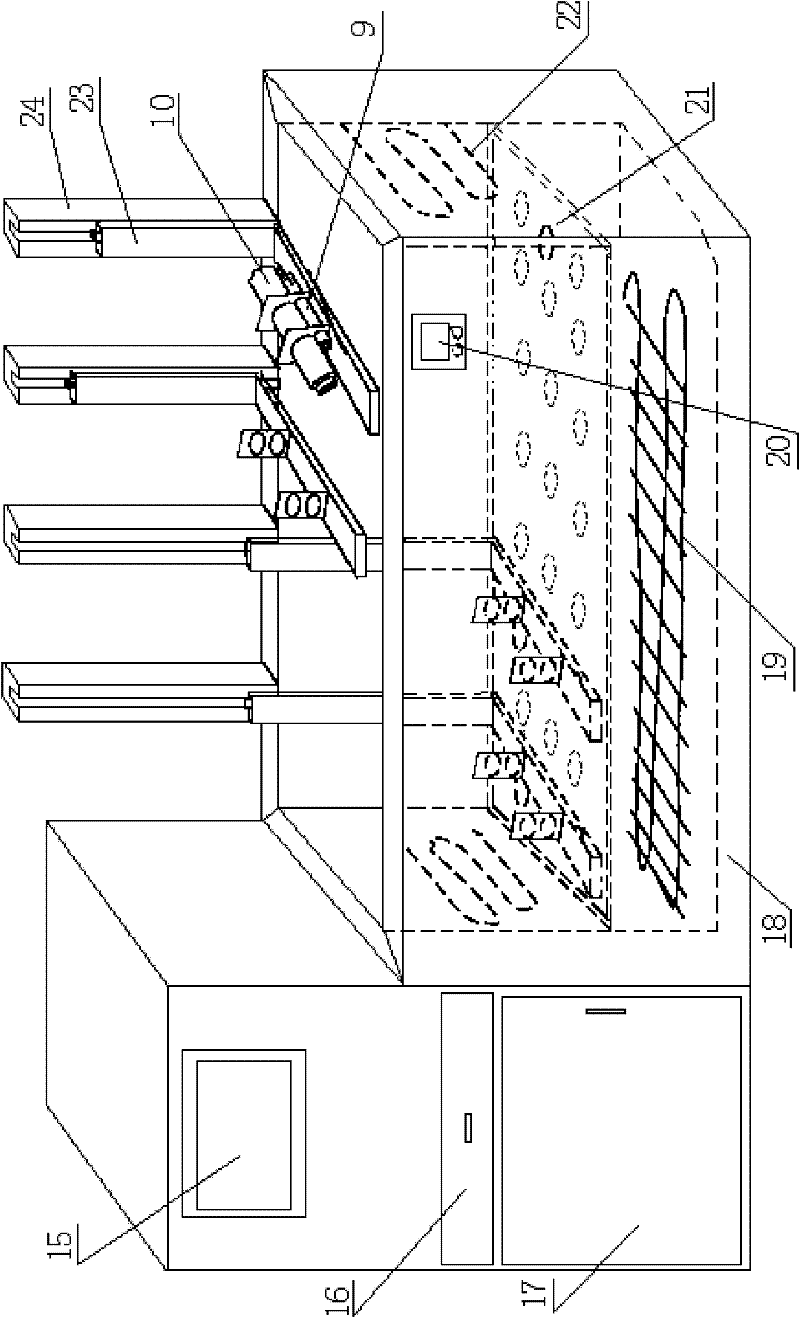

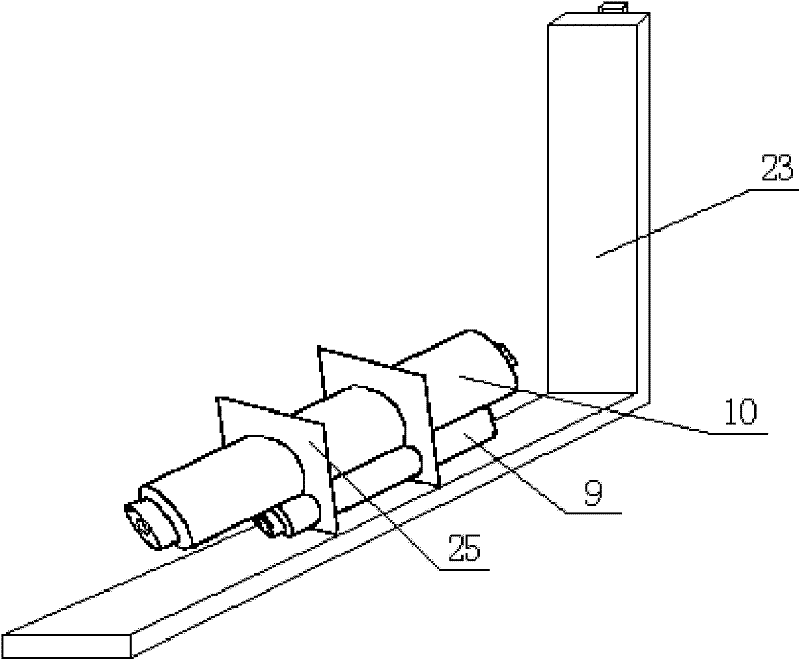

[0032] High temperature and high pressure adsorption tester, including gas pressurization device, adsorption device, temperature control device, lifting device and data acquisition system.

[0033] refer to figure 1 . The gas pressurization device is mainly composed of helium cylinder 1, pneumatic switching valve 2, safety valve 3, shuttle valve 4, booster pump 5, electric control valve A6, pressure transmitter A7 and pneumatic switching valve 8, two pneumatic The on-off valve 2 is respectively connected to the gas outlet of a helium cylinder 1 through a pipeline, the outlet of the pneumatic on-off valve 2 is respectively connected to a safety valve 3, the outlets of the two safety valves 3 are connected to a shuttle valve 4, and the outlet of the shuttle valve 4 is connected to a Haskel The AG-30 booster pump 5 boosts the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com