Waste gas treatment thermal cycle drying system

A technology for waste gas treatment and drying system, which is applied in the fields of surface pretreatment, electrical components, climate sustainability, etc. It can solve the problems of high production cost, inability to manufacture large-width backplanes, stretching deformation, etc., and save electricity costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] According to the claims of the present invention and the content disclosed in the specification, the technical solution of the present invention is specifically described as follows.

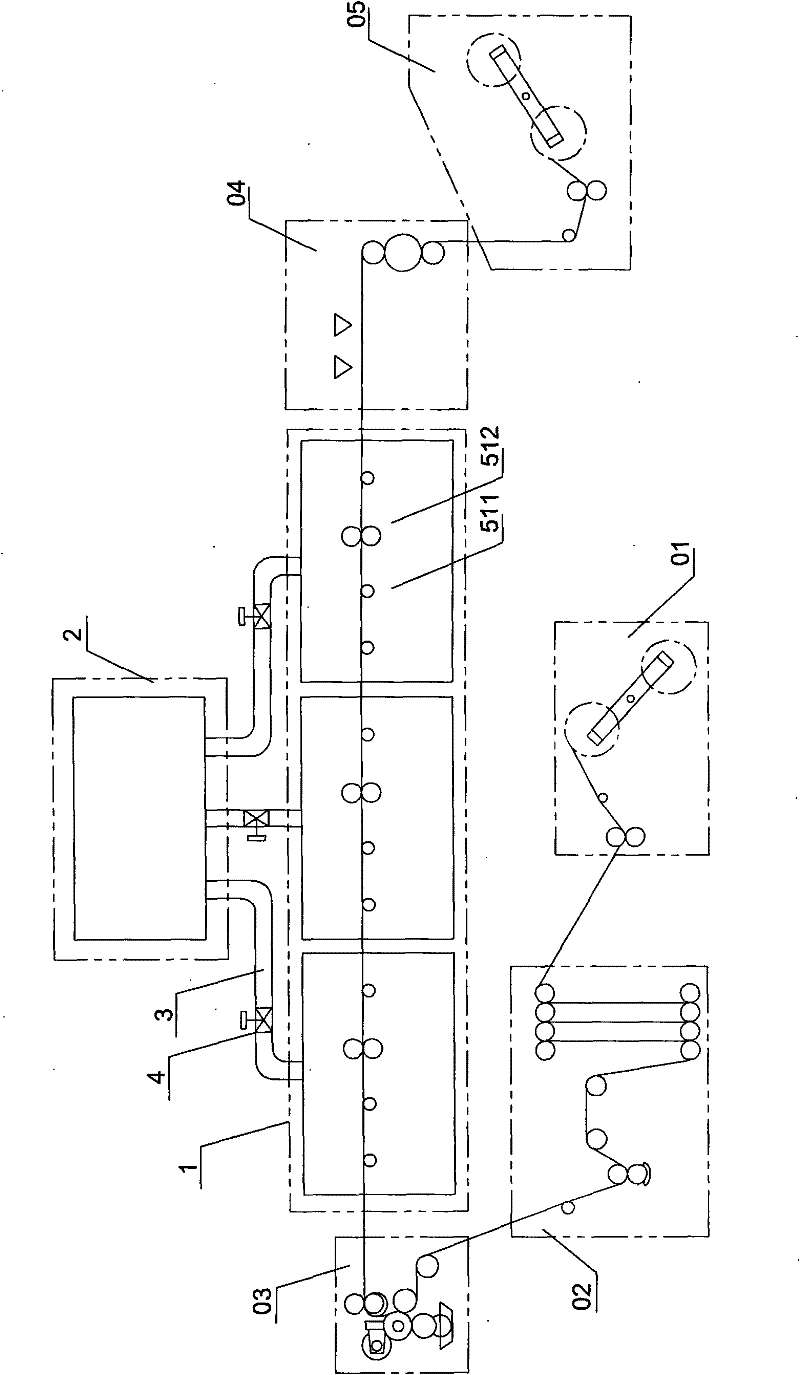

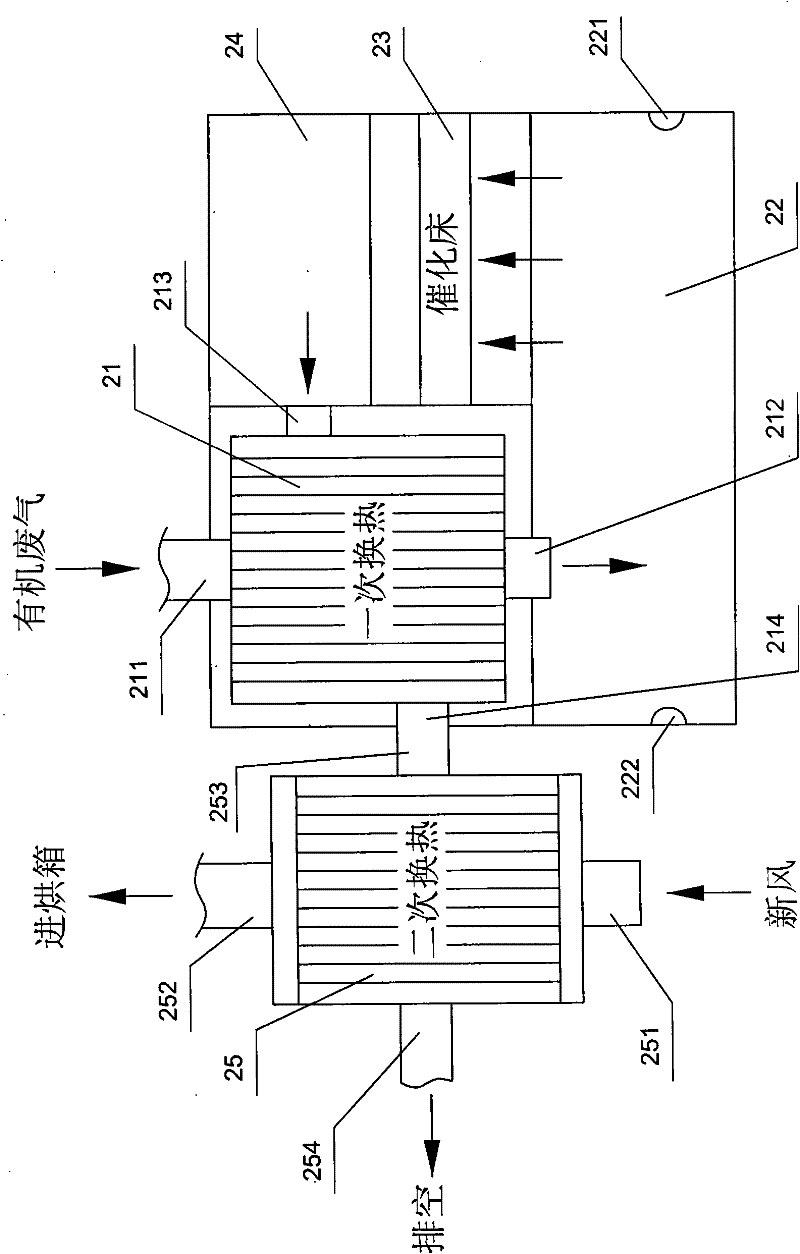

[0062] Such as figure 1 As shown in the prior art, the manufacturing device for the backsheet of a solar battery pack includes an unwinding device 01 , a pretreatment device 02 , a coating device 03 , a cooling system 04 and a winding device 05 connected in sequence. The waste gas treatment thermal cycle drying system of the present invention is arranged between the coating device 03 and the cooling system 04, and is used to dry the coated base film and transfer it to the cooling system for cooling.

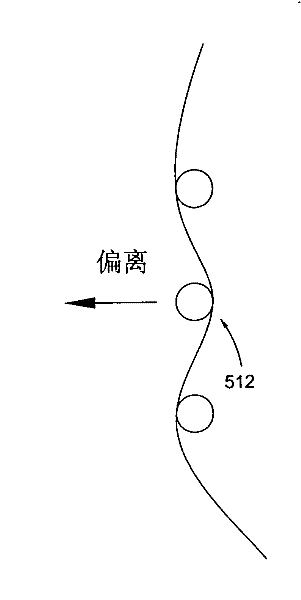

[0063] Such as figure 1 As shown, the exhaust gas treatment heat circulation drying system of the present invention comprises the following structure:

[0064] A group of ovens 1, the ovens 1 are connected in series to form a segmented multi-stage drying system;

[0065] A waste gas treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com