Aqueous coating composition

A technology for water-based coatings and compositions, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficulty in exerting coating properties and poor curing properties, and achieve excellent low-temperature curing properties and excellent coating properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

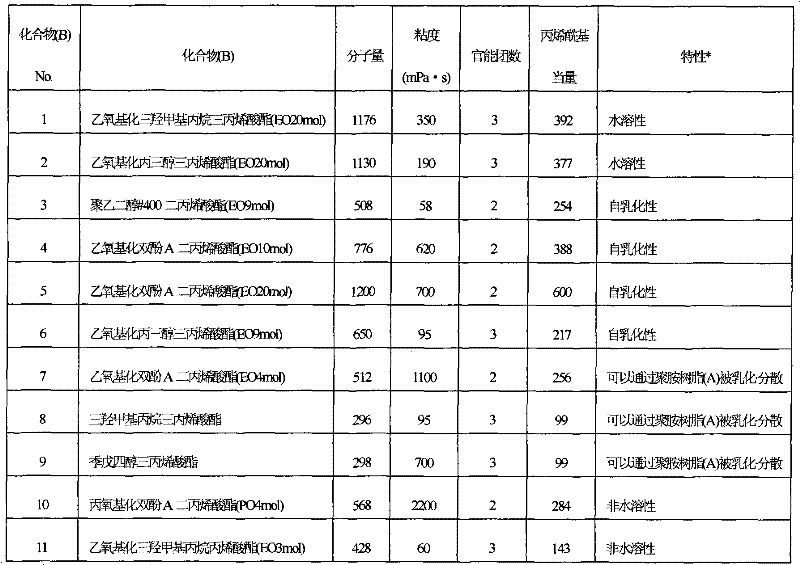

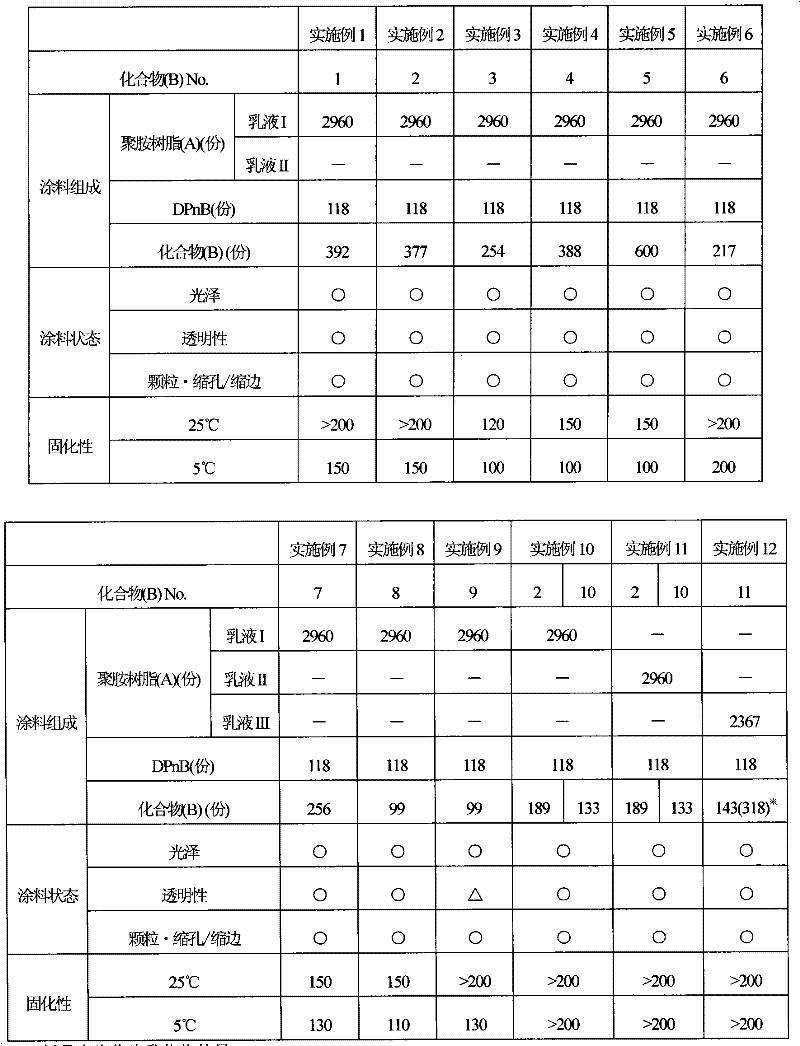

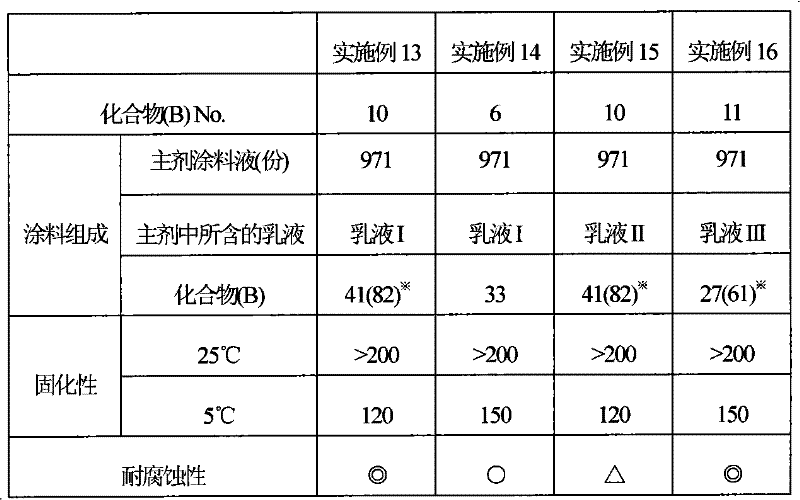

[0066] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples. In addition, parts and % in Examples are based on weight unless otherwise specified. In addition, the evaluation items in the examples are as follows.

[0067] (coating state)

[0068] The glass plates obtained by applying and drying the coatings obtained in Examples and Comparative Examples at 25°C (24 hours) were visually inspected to evaluate coating film abnormalities such as gloss, transparency, particles, craters, and edge shrinkage. .

[0069] Gloss ○: Coated film with high gloss

[0070] △: Semi-gloss coating film

[0071] ×: Dull coating film

[0072] Transparency ○: Completely or almost no cloudy coating film

[0073] △: Slightly cloudy coating film

[0074] ×: Coated film with severe turbidity

[0075] Abnormal coating film ○: Coating film completely or almost free of particles, shrinkage cavity / edge shrinkage...

manufacture example 1

[0087] [Manufacturing example 1] Production of polyamine resin (epoxy polyamine resin)

[0088] Add 702 parts of epoxy resins, 269 parts of bisphenol A, 108 parts of dimer acid, 190 parts of methyl isobutyl ketone (hereinafter referred to as "MIBK") was reacted at 117° C. until the epoxy equivalent became 1,270 in the presence of 1 part of benzyldimethylamine. Then, 255 parts of ketimine compounds (73 mass % MIBK solution) of aminoethylethanolamine were added, and it was made to react at 117 degreeC for 1 hour. Thereafter, it was diluted with MIBK until the non-volatile content was 75%, and an epoxy-based polyamine resin having a number average molecular weight of 2400 and an amine equivalent of 1184 was obtained.

manufacture example 2

[0089] [Manufacturing example 2] Emulsification of epoxy-based polyamine resin

[0090] Acetic acid was added to the epoxy polyamine resin obtained in Production Example 1 so that the neutralization rate was 20.0% (neutralization rate with respect to the amine groups of the resin), and ion-exchanged water was added for dilution. Thereafter, the mixture of MIBK and water was removed under reduced pressure until the solid content was 40% by mass to prepare emulsion I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com