Indirect evaporative cooler using membrane-contained, liquid desiccant for dehumidification

An evaporative cooler and liquid desiccant technology, applied in indirect heat exchangers, natural cooling systems, energy-saving heating/cooling, etc., can solve problems such as corrosion, expensive purchase, operation, and maintenance, and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

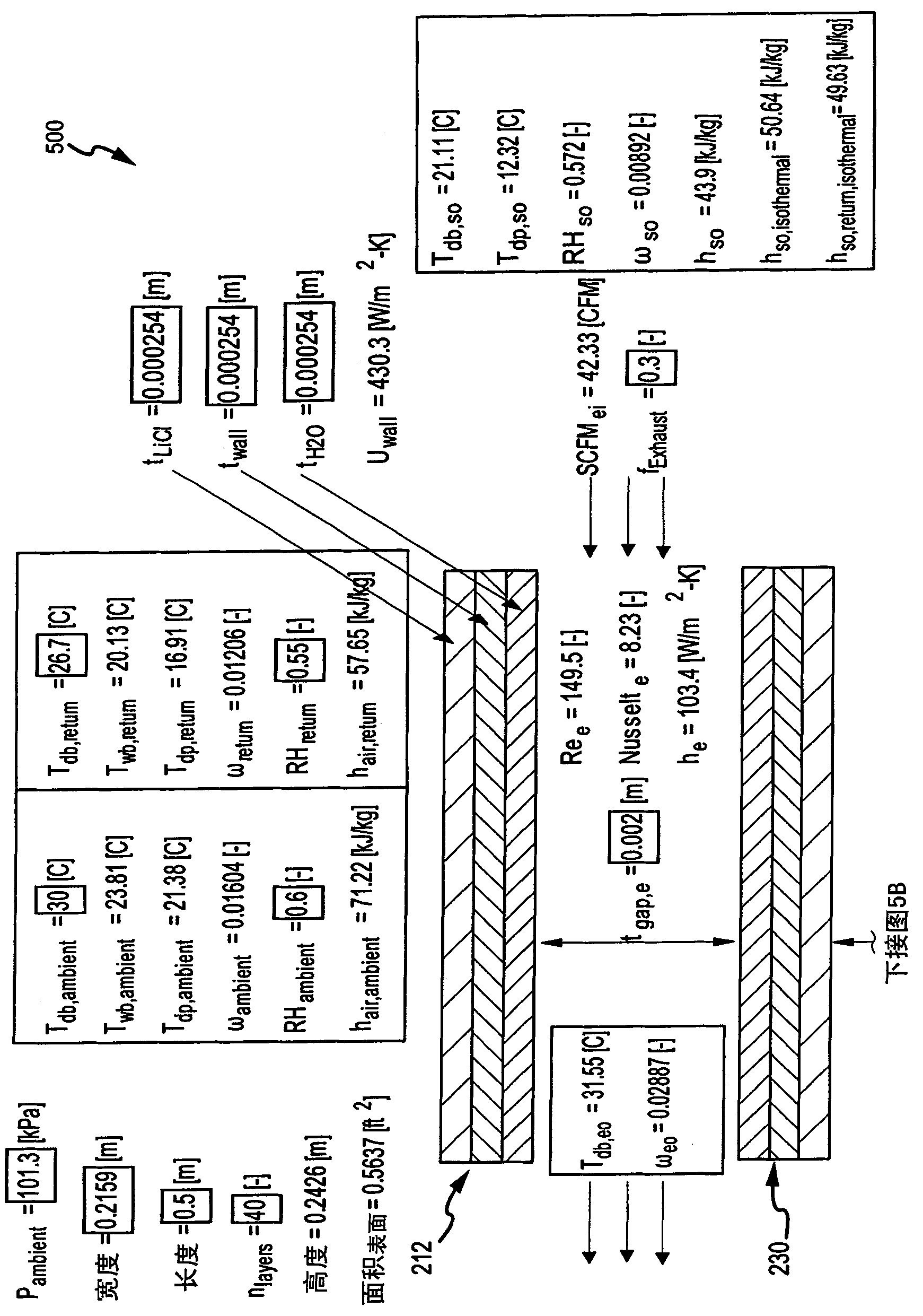

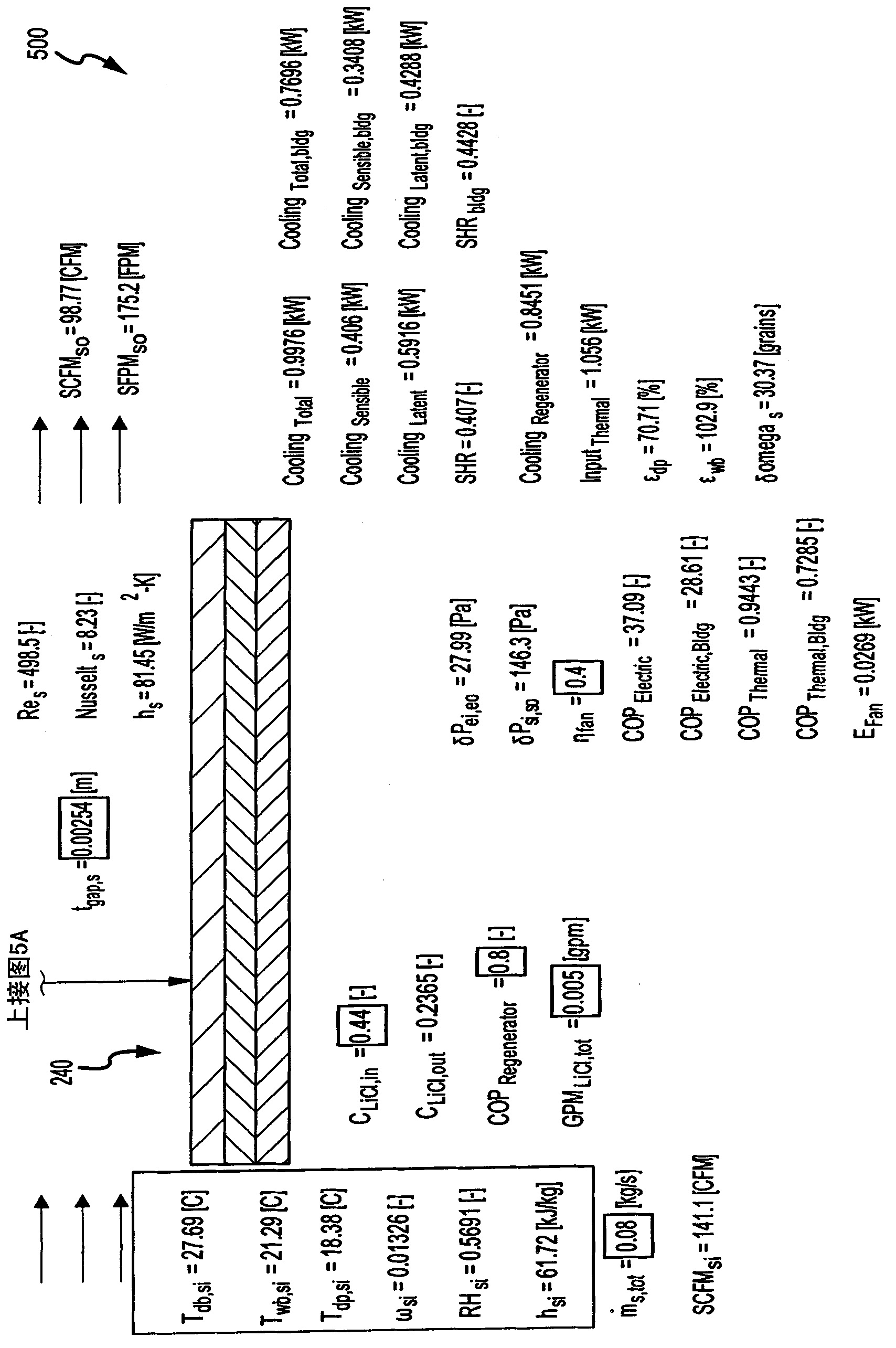

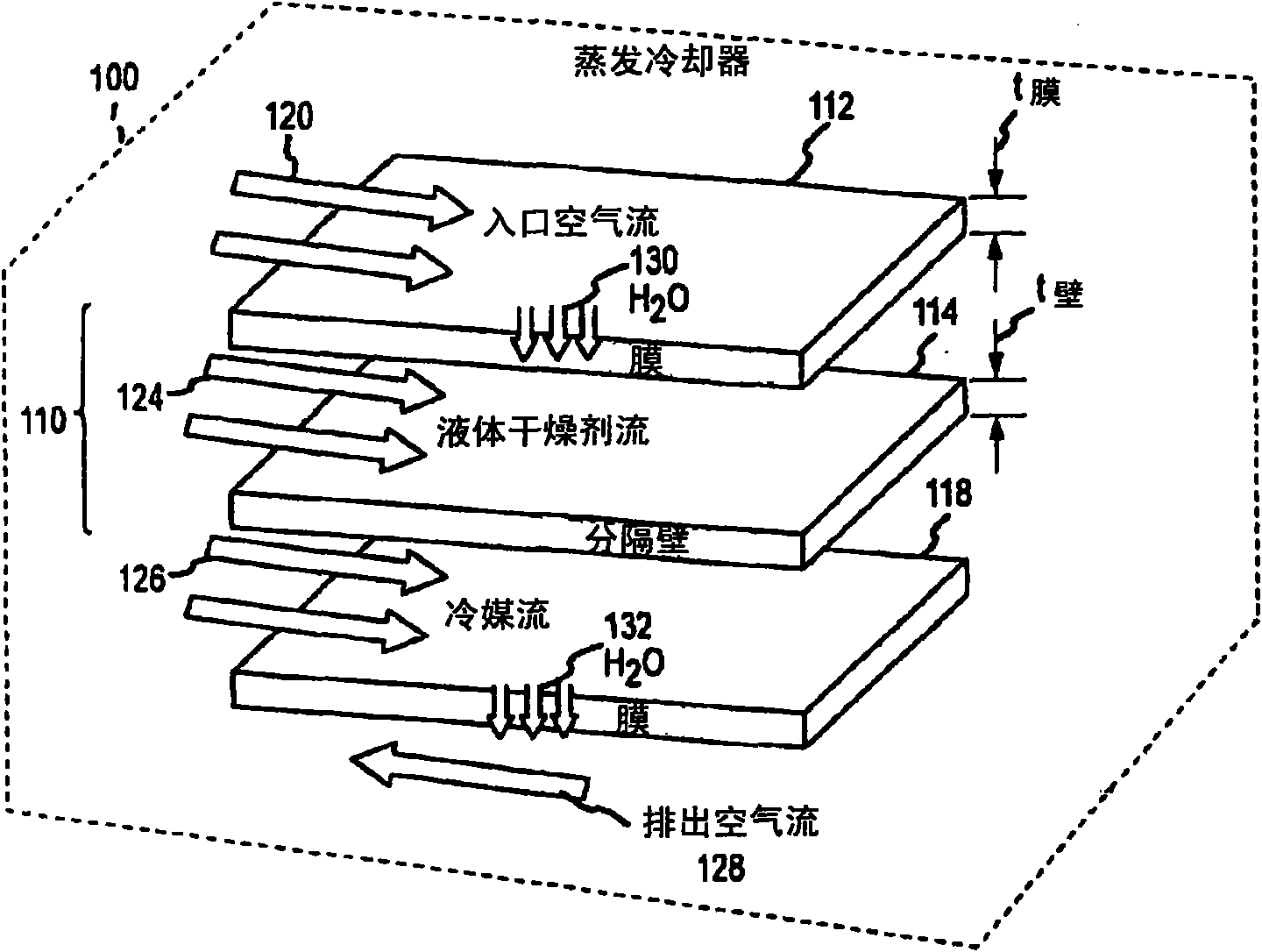

[0033] A description of an exemplary indirect evaporative cooler with dehumidification and mass / heat transfer components for a cooler that provides an inlet airflow chamber with an optional evaporative cooling system that encloses a liquid desiccant is provided next. The side wall defined by the permeable membrane. The assembly also includes an outlet or exhaust airflow chamber (eg, counter-flow to the inlet airflow) with side walls defined by a permeable membrane enclosing a refrigerant, such as water. In the embodiments described below, the membrane is "permeable" in the sense that moisture in the form of vapor (e.g., water in vapor state) can generally readily permeate, such as via evaporation, from the inlet supply air and liquid refrigerant through the membrane. However, the membrane generally traps or blocks the flow of moisture in liquid form, which instead is directed to flow within the channels or chambers. In some cases, liquid water is trapped within the membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com