Drill bucket capable of opening bucket door continuously to discharge soil forcibly

A technology of drilling bucket and door opening device, which is applied in the direction of earthwork drilling, drill bit, drilling equipment, etc. It can solve the problems that affect the use of drilling bucket, unfavorable soil unloading, unovercome disadvantages, etc., so as to improve reliability, avoid damage, impact force, etc. gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

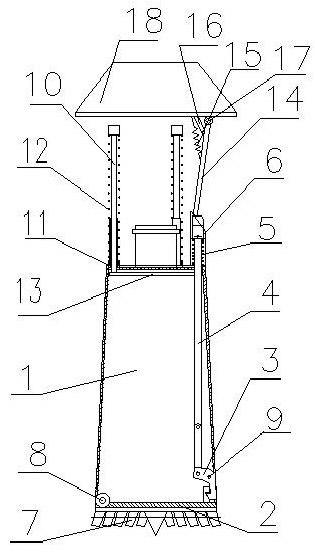

[0024] Example 1: In figure 1 In the shown drill bucket that can continuously open the bucket door and forcibly unload soil, the drill bucket includes a drill bucket body 1, a door opening mechanism, a drill bucket bottom door 2, and a soil unloading mechanism. The drill bucket bottom door 2 is located under the drill bucket body 1. At the port, one end of the bottom door 2 of the drilling bucket is provided with a lock, which matches with the door hook 3 of the door opening mechanism. 1 is provided with a bulldozer plate 13 in the inner cavity, and the bulldozer plate 13 is provided with a bulldozer lever 10, and the bulldozer lever 10 passes through the bulldozer guide sleeve 11 positioned at the top of the drill bucket body 1, and the bulldozer lever 10 The bulldozing return spring 12 is set on the body part of the drilling bucket; the door opening mechanism includes a push-down device installed on the pressure plate 18 of the drilling rig and a door-opening device installe...

Embodiment 2

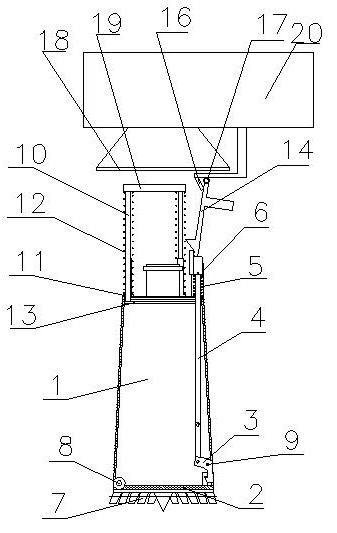

[0026] Example 2: In figure 2 In the shown drill bucket that can continuously open the bucket door and forcibly unload soil, the drill bucket includes a drill bucket body 1, a door opening mechanism, a drill bucket bottom door 2, and a soil unloading mechanism. The drill bucket bottom door 2 is located under the drill bucket body 1. At the port, one end of the bottom door 2 of the drilling bucket is provided with a lock, which matches with the door hook 3 of the door opening mechanism. 1 is provided with a bulldozer plate 13 in the inner cavity, and the bulldozer plate 13 is provided with a bulldozer lever 10, and the bulldozer lever 10 passes through the bulldozer guide sleeve 11 positioned at the top of the drill bucket body 1, and the bulldozer lever 10 Going out of the drill bucket body part is covered with a bulldozer return spring 12; the door opening mechanism includes a push-down device installed on the power head 20 of the drilling rig and a door-opener installed on ...

Embodiment 3

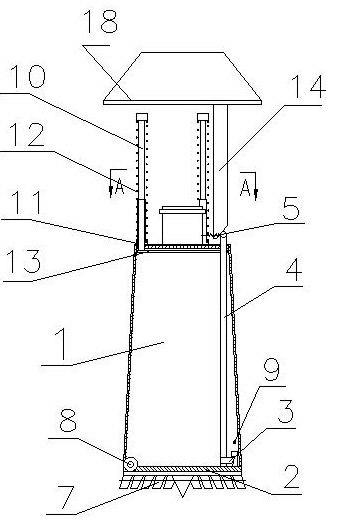

[0028] Example 3: In image 3 with Figure 4 In the shown drill bucket that can continuously open the bucket door and forcibly unload soil, the drill bucket includes a drill bucket body 1, a door opening mechanism, a drill bucket bottom door 2, and a soil unloading mechanism. The drill bucket bottom door 2 is located under the drill bucket body 1. At the port, one end of the bottom door 2 of the drilling bucket is provided with a lock, which matches with the door hook 3 of the door opening mechanism. 1 is provided with a bulldozer plate 13 in the inner cavity, and the bulldozer plate 13 is provided with a bulldozer lever 10, and the bulldozer lever 10 passes through the bulldozer guide sleeve 11 positioned at the top of the drill bucket body 1, and the bulldozer lever 10 The bulldozing return spring 12 is set on the body part of the drilling bucket; the door opening mechanism includes a push-down device installed on the pressure plate 18 of the drilling rig and a door-opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com