System for monitoring wear of pantograph sliding plate

A pantograph sliding plate and monitoring system technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as low efficiency, poor accuracy, and easy misjudgment, achieve high efficiency and accuracy, and avoid pantograph-catenary accidents. , the effect of not easily misjudged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

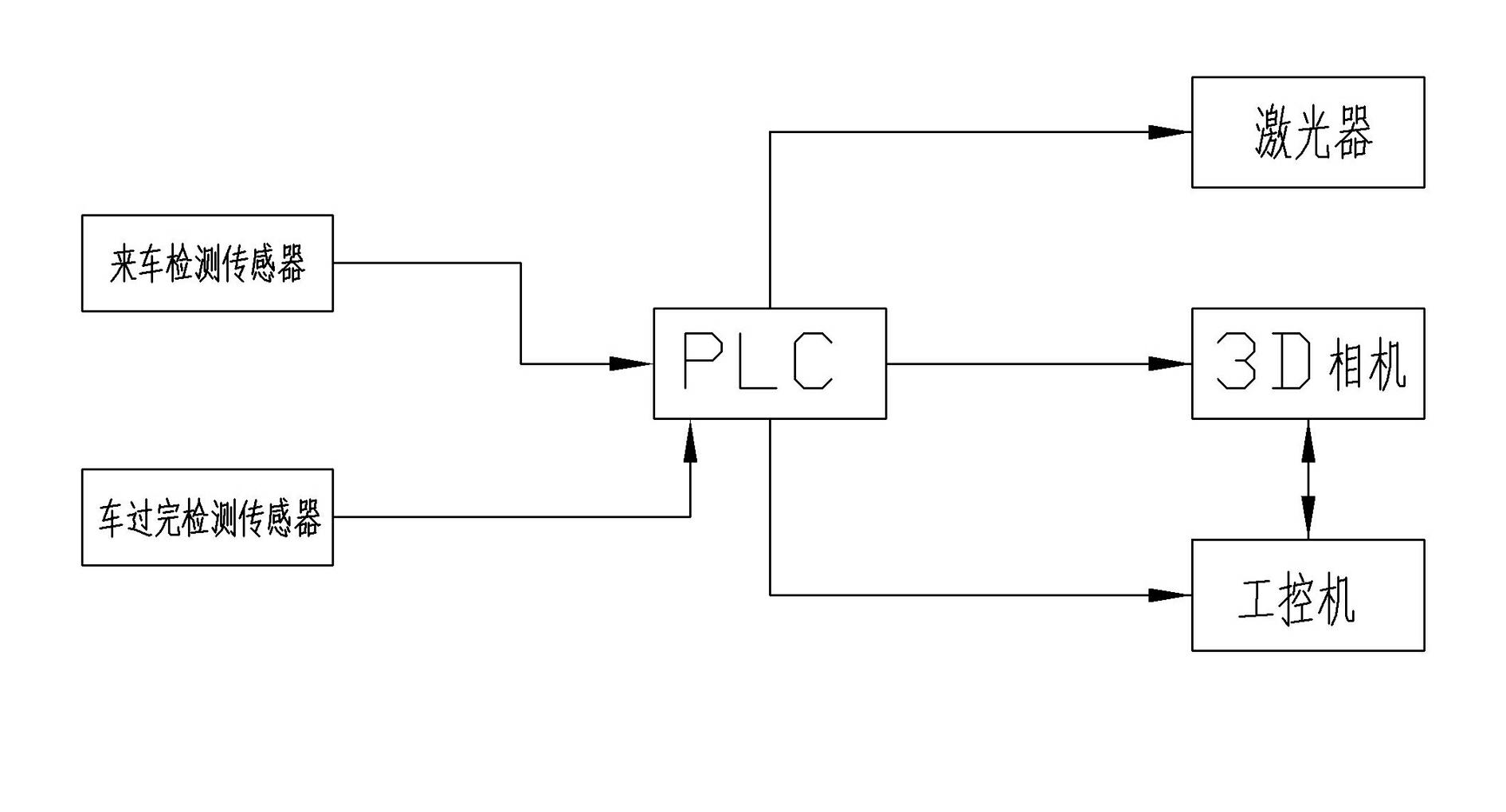

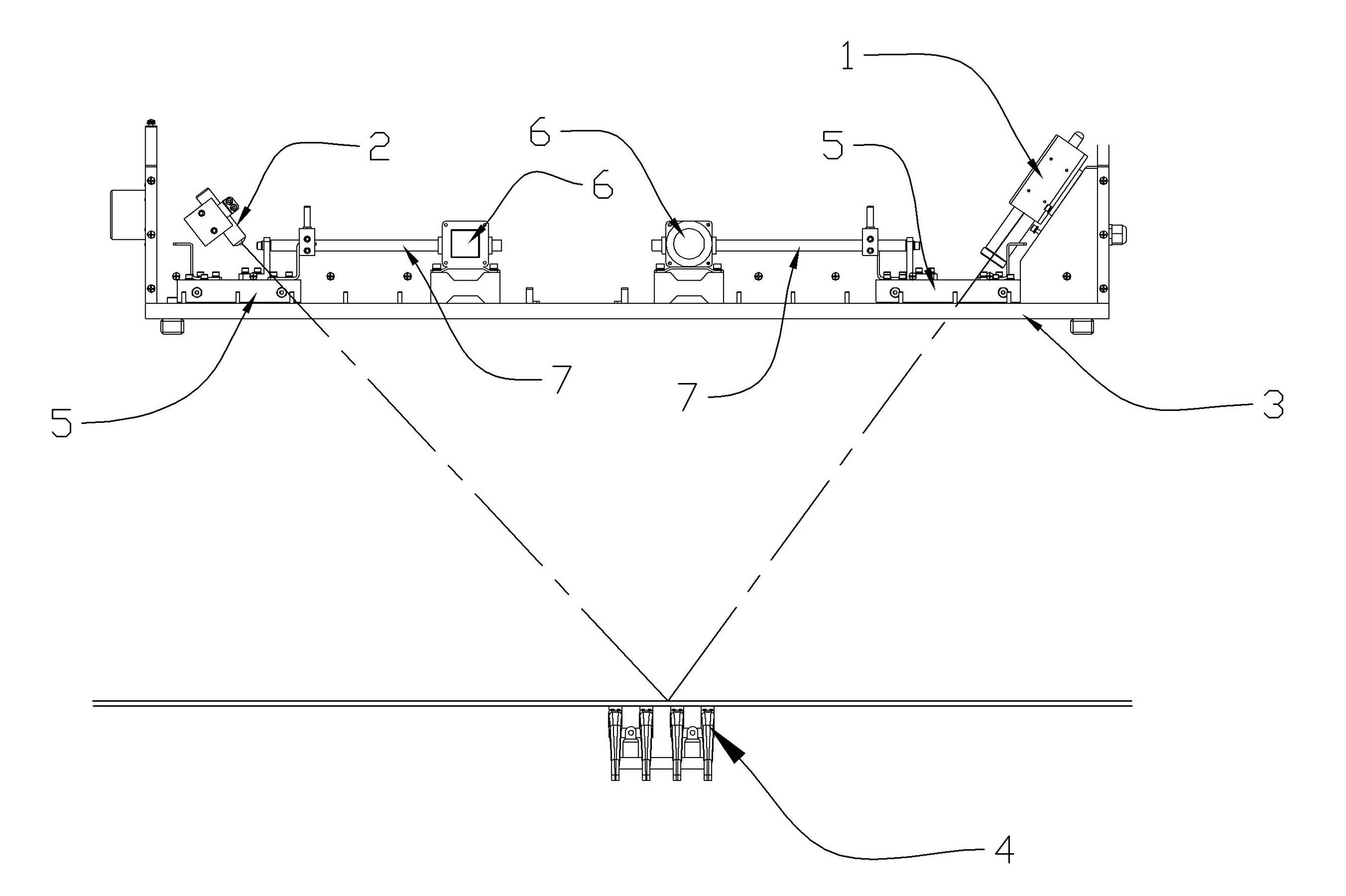

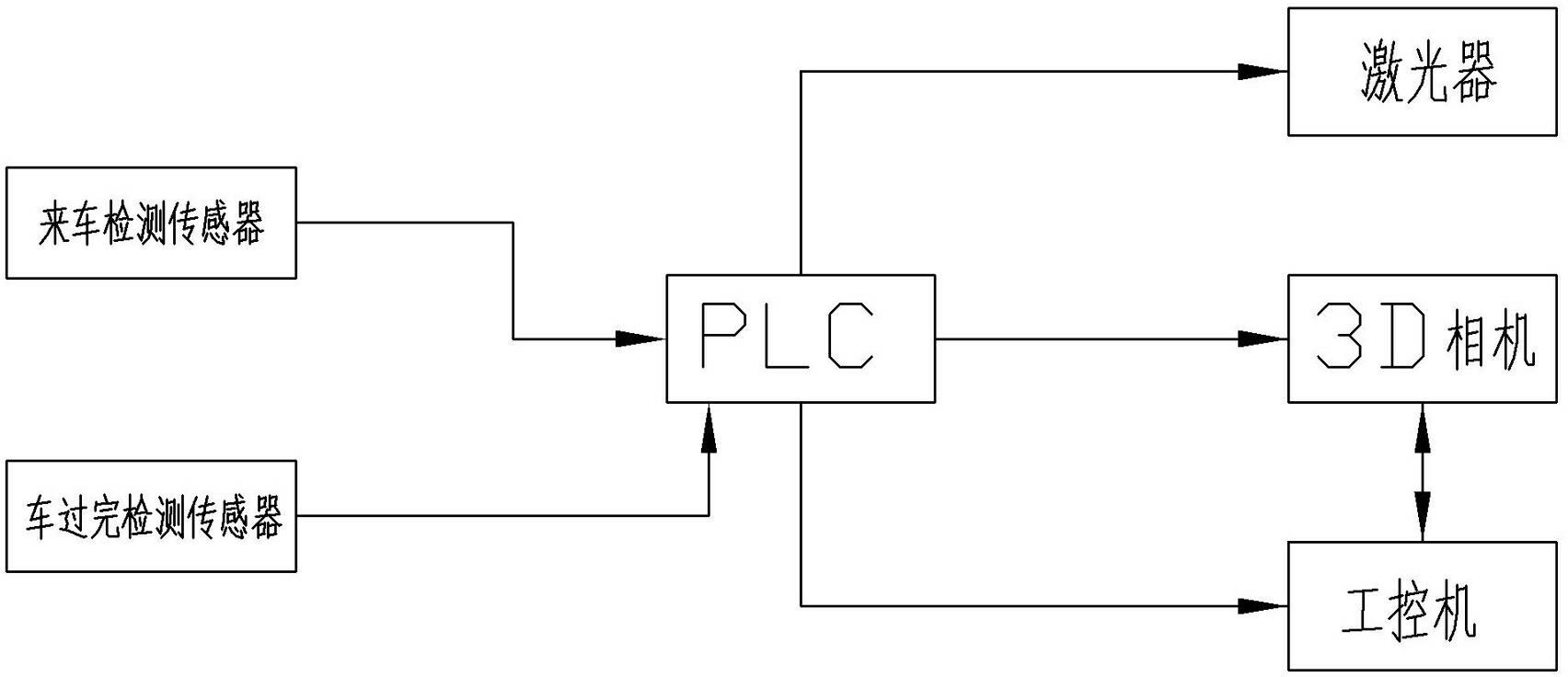

[0010] like figure 1 , one A pantograph slide wear monitoring system, including a three-dimensional stereo camera 1 (3D camera) and a laser 2; the 3D camera and the laser are installed above the monitoring place, which can be installed above the monitoring place through a fixed frame 3, relative to the fixed frame It can be rotated, and the angle can be adjusted by rotating after installation, so that when the pantograph 4 passes by, the laser can fully and clearly illuminate the pantograph, and the 3D camera can fully and clearly photograph the pantograph. For example, adjust the laser so that the irradiating light can fully and clearly cover the pantograph passing through the bottom, and the 3D camera can be set symmetrically with it, and the incident light of the laser is reflected by the pantograph slide and just irradiates the lens direction of the 3D camera. The 3D camera and laser are connected to the PLC controller, and the PLC controller controls the switch of its p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com