Loading method for concrete member flexural test

A concrete and component technology, applied in the direction of applying a stable bending force to test the strength of materials, can solve the problems of increased test workload and difficult to continue to use, and achieve the effect of small slippage, simple structure and reliable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

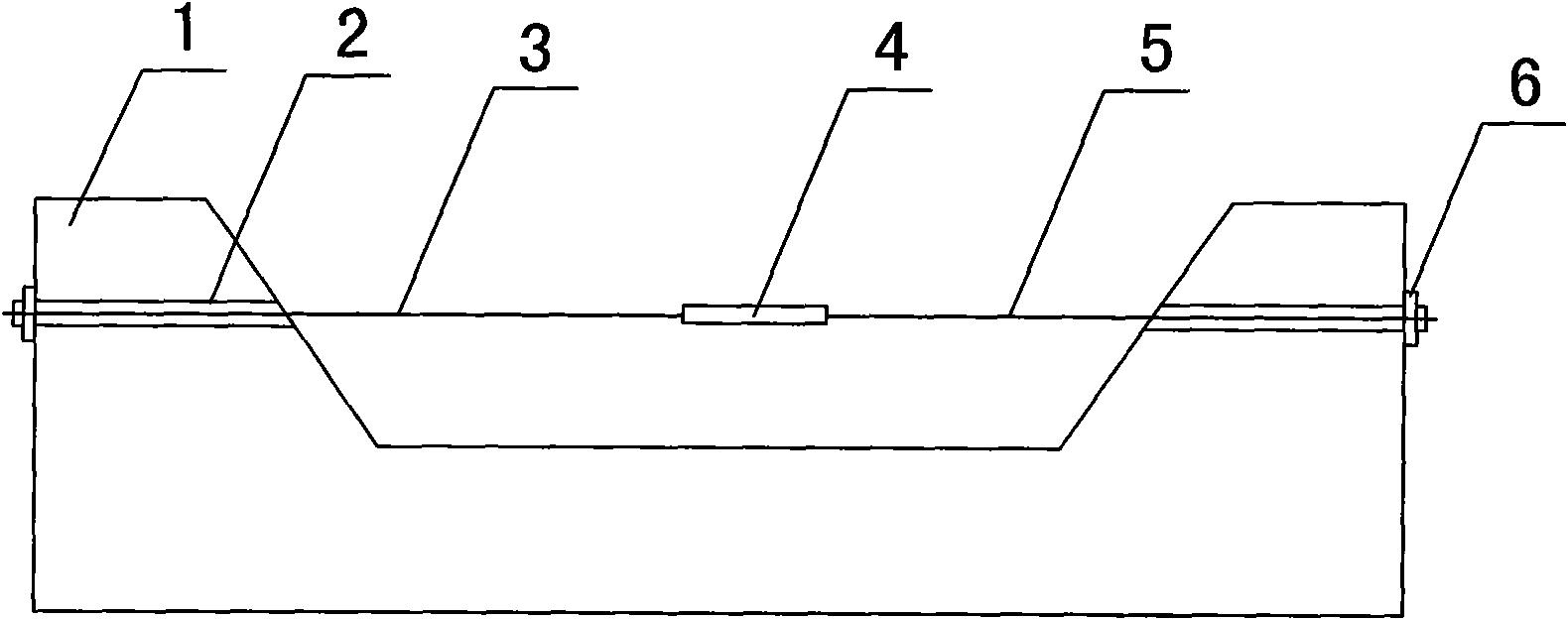

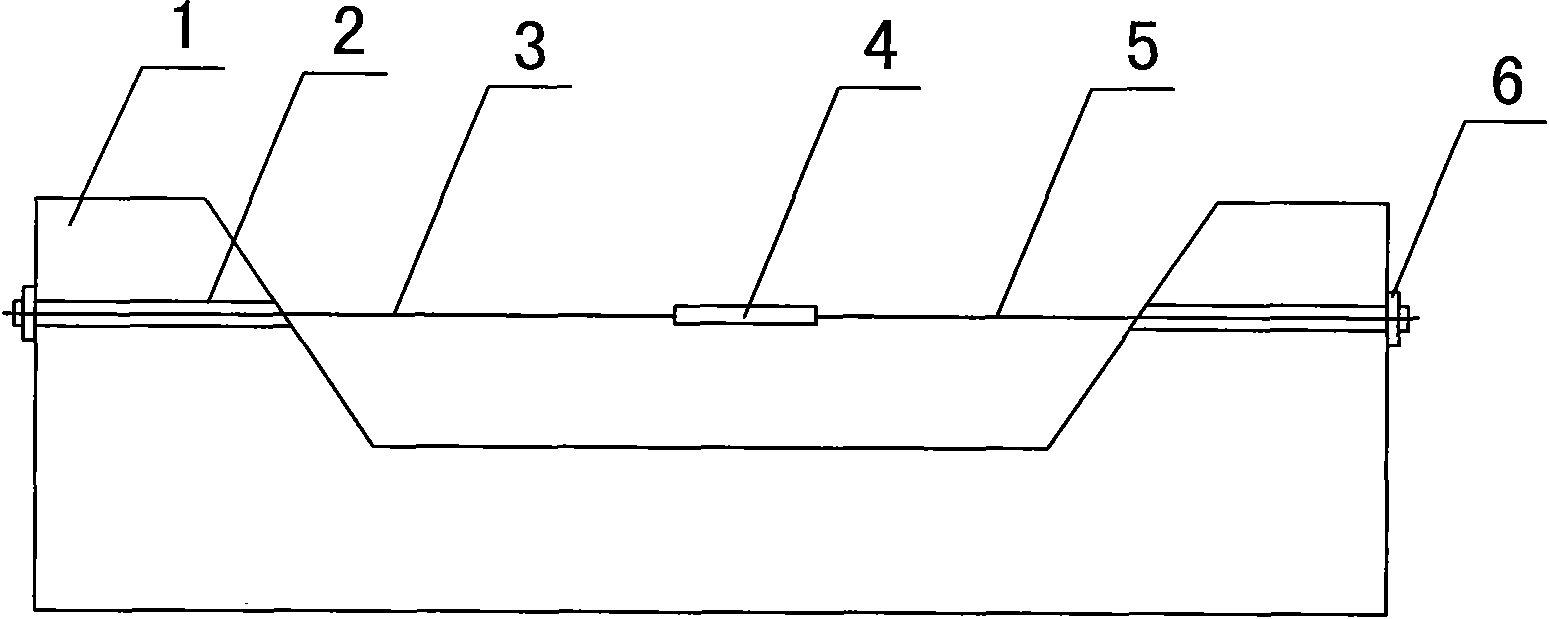

[0025] Such as figure 1 As shown, pouring plain concrete (or reinforced concrete) component 3, the concrete component is 800mm long, 100mm wide, and 100mm high. Corbels 1 are set at both ends of the concrete member. The height of the corbel is 150mm, the length of the bottom of the corbel is 200mm, and the length of the upper end of the corbel is 100mm. The corbel and the concrete member are poured into one body at the same time. Leave the circular tunnel 2 (the tunnel diameter is 30mm, it is advisable to pass through the screw end rod), the holes of the two circular tunnels are on the same axis, and the steel plate with holes is embedded in the tunnel outside. After pouring, the concrete components were cured for 28 days according to the existing concrete curing conditions and methods (according to the current national standard "Test Method for Mechanical Properties of Ordinary Concrete"), the strength of the concrete was measured, and the cracking load of the concrete compon...

Embodiment 2

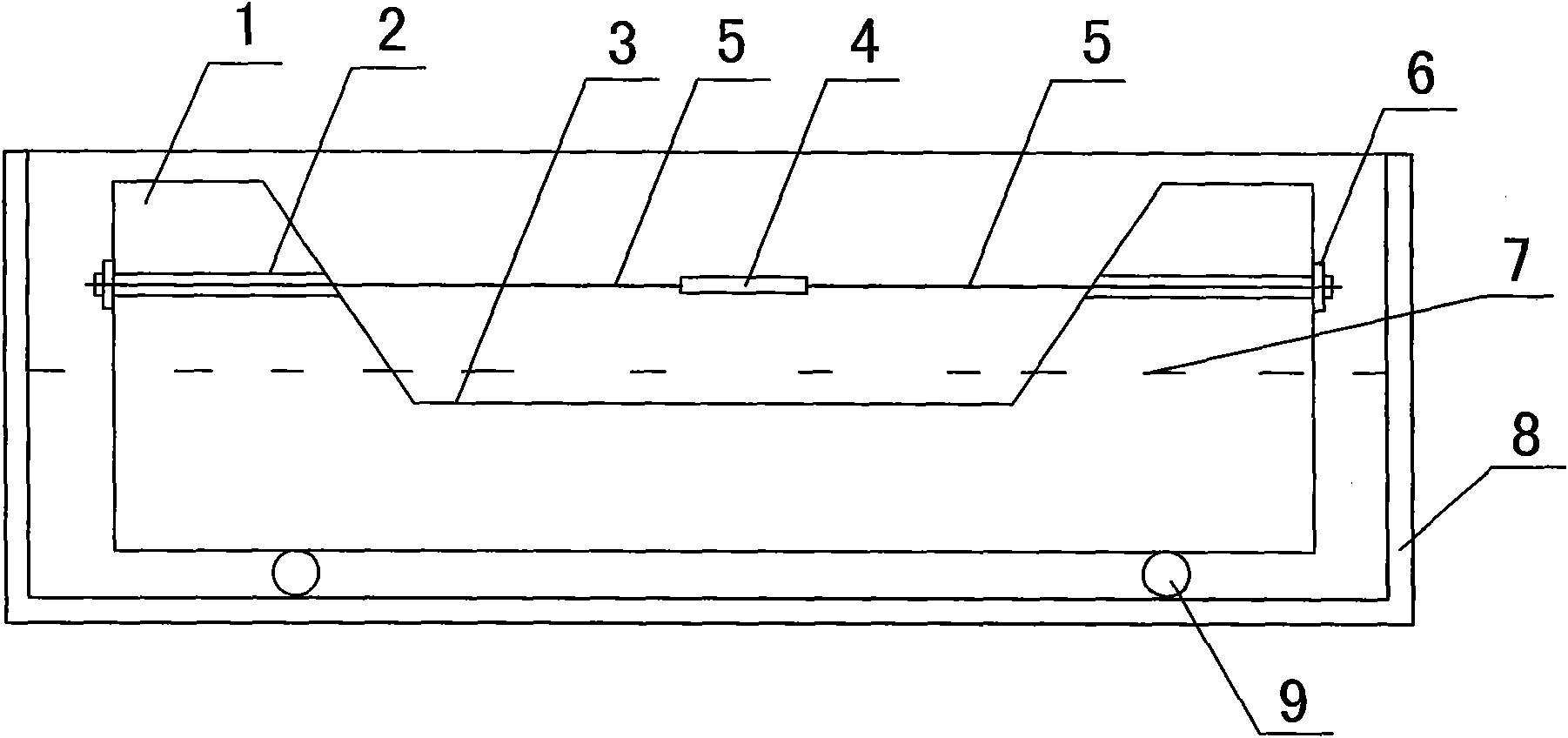

[0027] Such as figure 2 as shown in figure 1 As shown, pouring plain concrete (or reinforced concrete) component 3, the concrete component is 800mm long, 100mm wide, and 100mm high. Corbels 1 are set at both ends of the concrete member. The height of the corbel is 150mm, the length of the bottom of the corbel is 200mm, and the length of the upper end of the corbel is 100mm. The corbel and the concrete member are poured into one body at the same time. Leave the circular tunnel 2 (the tunnel diameter is 30mm, it is advisable to pass through the screw end rod), the holes of the two circular tunnels are on the same axis, and the steel plate with holes is embedded in the tunnel outside. After pouring, the concrete components were cured for 28 days according to the existing concrete curing conditions and methods (according to the current national standard "Test Method for Mechanical Properties of Ordinary Concrete"), the strength of the concrete was measured, and the cracking load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com